Method for preparing N,N'-bi(alkyl)-p-phenylenediamine

A technology of p-phenylenediamine and alkyl, applied in the field of preparation of N,N'-bis-p-phenylenediamine, which can solve the problems of harsh preparation conditions and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

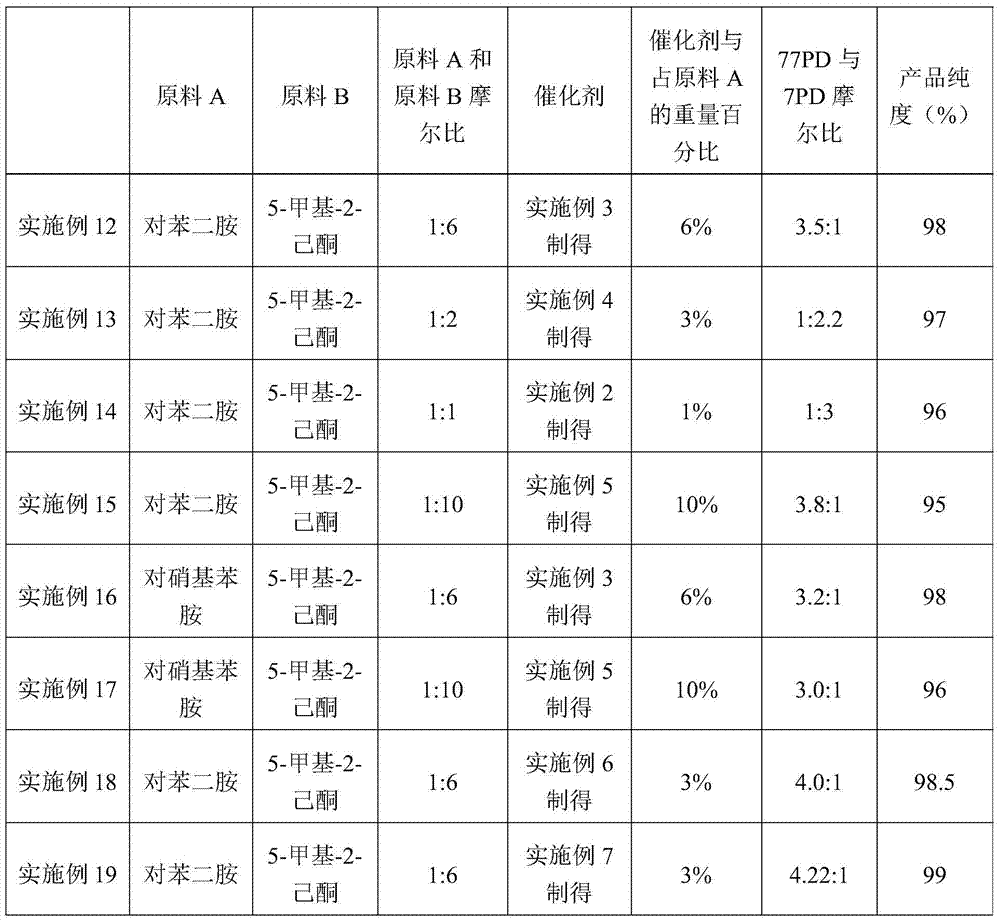

Examples

preparation example Construction

[0024] As described in the background art section, the existing preparation method of N,N'-bis(alkyl)-p-phenylenediamine has harsh conditions and low yield. In order to solve this problem, the present invention provides a preparation method of N,N'-bis(alkyl)-p-phenylenediamine, which comprises the following steps: mixing raw material A and raw material B and reacting to obtain a reaction liquid, The reaction solution is dehydrated to obtain a Schiff base intermediate; hydrogen is introduced into the Schiff base intermediate, and a reduction reaction is carried out under the catalysis of a supported nanocomposite metal catalyst to obtain N,N'-bis(alkyl )-p-phenylenediamine; Wherein, raw material A is p-phenylenediamine and / or p-nitroaniline, and raw material B is alkyl ketone.

[0025] The above preparation method provided by the present invention adopts a two-step method to prepare N,N'-bis(alkyl)-p-phenylenediamine, specifically: first, p-phenylenediamine or p-nitroaniline a...

Embodiment 1

[0037] In this example, a supported nanocomposite metal catalyst Cu-Pd / TiO was prepared 2 (where TiO 2 For catalyst carrier, Pd and Cu are respectively the first active component and the second active component), and the preparation method is as follows:

[0038] Weigh 10 g of nanocrystalline titanium dioxide, add 150 ml of deionized water to stir, and prepare a slurry at a temperature of 80° C. after heating in a water bath. Slowly add 10ml of Cu(NO 3 ) 2 solution (Cu content is 0.27g / ml) and 6ml of H 2 PdCl 4 solution (Pd content is 0.01g / ml), stirring and impregnating at constant temperature for 5h. Then, NaOH solution with a mass concentration of 10% was added dropwise to the mixed solution, the pH value was adjusted to be between 8 and 10, and the temperature of the solution was kept and stirred for another 5 hours. Then filter the reaction solution, wash the filter cake with deionized water until neutral, vacuum dry at 90-150°C for 2 hours, then vacuum roast at 200...

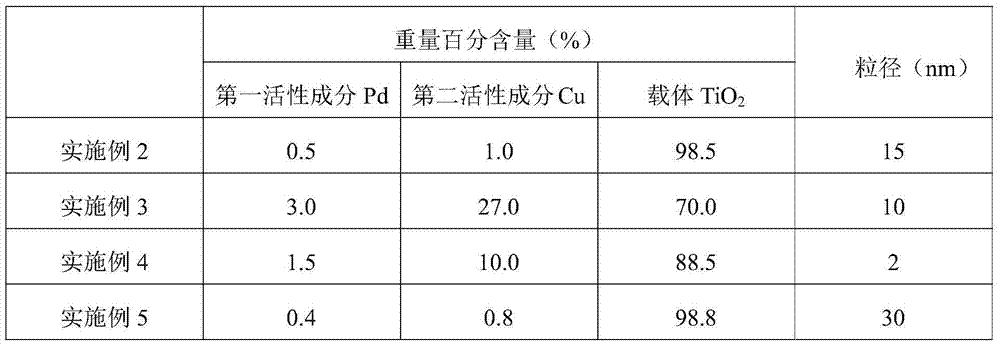

Embodiment 2 to 5

[0040] All prepared supported nanocomposite metal catalyst Cu-Pd / TiO in this embodiment 2 , the process condition of preparation is the same as embodiment 1, and difference is the ratio and particle diameter of catalyst support, first active ingredient and second active ingredient, and concrete ratio is as follows:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com