Colored curable resin composition

A technology of curable resin and composition, applied in nonlinear optics, optics, optomechanical equipment, etc., can solve problems such as colorant sublimation, and achieve the effect of inhibiting sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] In the preparation of the compound (1), relative to 1 mole of the compound represented by the formula (q2), the amount of the compound represented by the formula (q1) is preferably 1 mole to 10 moles, more preferably 1 mole to 4 moles, and even more preferably It is 1 mol to 3 mol, more preferably 1 mol.

[0085] In the preparation of compound (1), relative to 1 mole of the compound represented by formula (q2), the amount of ethyl cyanoacetate is preferably 1 mole to 10 moles, more preferably 1 mole to 4 moles, and even more preferably 1 mole to 1 mole. 3 moles, more preferably 1 mole.

[0086] In the preparation of compound (1), relative to 1 mole of the compound represented by formula (q2), the amount of benzoic acid is preferably 0.1 moles to 3 moles, more preferably 0.3 moles to 3 moles, even more preferably 0.3 moles to 1.2 moles , and more preferably 0.3 to 0.4 mol.

[0087] The method for obtaining the target compound (1) from the reaction mixture is not partic...

Embodiment

[0285] Next, an Example etc. are given and this invention is demonstrated more concretely.

[0286] In Examples and Comparative Examples, % and parts indicating content and usage are based on mass unless otherwise specified.

[0287] In the following examples, the structures of the compounds were confirmed by NMR (JMM-ECA-500; manufactured by JEOL Ltd.) or mass spectrometry (LC; Model 1200 manufactured by Agilent, MASS; Model LC / MSD6130 manufactured by Agilent).

[0288] The measurement of the weight average molecular weight (Mw) and the number average molecular weight (Mn) of the polystyrene conversion of resin was performed by the GPC method on the following conditions.

[0289] Device: HLC-8120GPC (manufactured by Tosoh Co., Ltd.)

[0290] Column; TSK-GELG2000HXL

[0291] Column temperature; 40°C

[0292] Solvent; THF

[0293] Flow rate; 1.0mL / min

[0294] Solid component concentration of the liquid to be tested; 0.001 to 0.01% by mass

[0295] Injection volume; 50μL ...

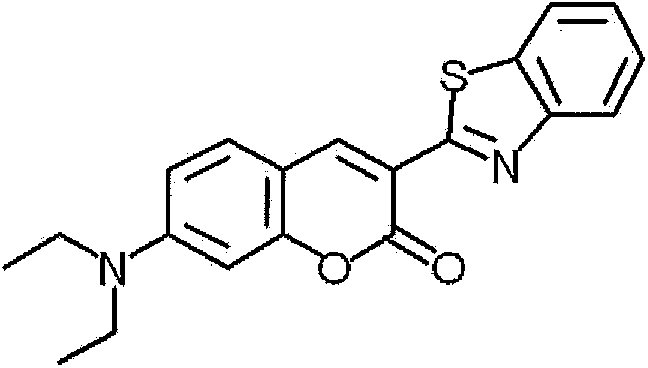

Synthetic example 1

[0302] Mix 10.0 parts of 4-amino-3-hydroxybenzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd.), 12.8 parts of 4-(diethylamino) salicylaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), benzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd. 2.73 parts of 1-pentanol (manufactured by Tokyo Chemical Industry Co., Ltd.), and 7.43 parts of ethyl cyanoacetate (manufactured by Tokyo Chemical Industry Co., Ltd.), were stirred at 120° C. for 3 hours. Add 7.46 parts of ethyl cyanoacetate (produced by Tokyo Chemical Industry Co., Ltd.), 2.79 parts of benzoic acid (produced by Tokyo Chemical Industry Co., Ltd.), 49.8 parts of 1-pentanol (produced by Tokyo Chemical Industry Co., Ltd.) and 4-( 12.7 parts of diethylamino) salicylaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.) was stirred at 120° C. for 14 hours. Add 3.76 parts of ethyl cyanoacetate (manufactured by Tokyo Chemical Industry Co., Ltd.), 1.41 parts of benzoic acid (manufactured by Toky...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com