Preheating tin soldering machine

A soldering machine and tin wire technology, applied in the direction of tin feeding device, electric heating device, welding equipment, etc., can solve the problems of large bending resistance, poor spinning, affecting the health of operators, etc., achieve small thermal shock and improve softness degree and surface smoothness, effect of suppressing sublimation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with implementation cases.

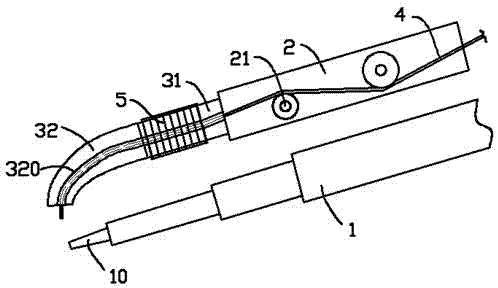

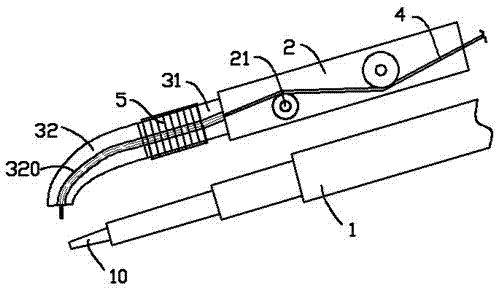

[0015] in figure 1 In the illustrated embodiment, the preheating soldering machine includes a base (non-improved part, not shown). A welding torch 1 and a wire torch extend in parallel in front of the base, and the wire torch includes a transfer arm 2 , The conveying arm 2 is provided with a conveying roller 21, and the tin wire 4 is drawn to extend to the spinning pipe in front of the conveying arm 2. The spinning pipe is divided into a straight pipe 31 and a spinning bend 32. The spinning elbow 32 is bent toward the gun head 10 of the welding torch 1, and the spinning pipe is provided with a spinning bend 320 through which the tin wire 4 passes; the spinning pipe is composed of a metal body and has a good The surface of the straight tube 31 is wound with an electric heating structure 5 composed of heating wires, which can make the tin wire 4 be heated and softened before it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com