A kind of color toner and preparation method thereof

A technology of color toner and toner, which is applied in the direction of instruments, optics, developer, etc., can solve the problems of high-efficiency coating of difficult resins, material leakage, uneven components, and uneven charges, and achieve simple preparation process conditions and charge distribution Uniform, grain-shaped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

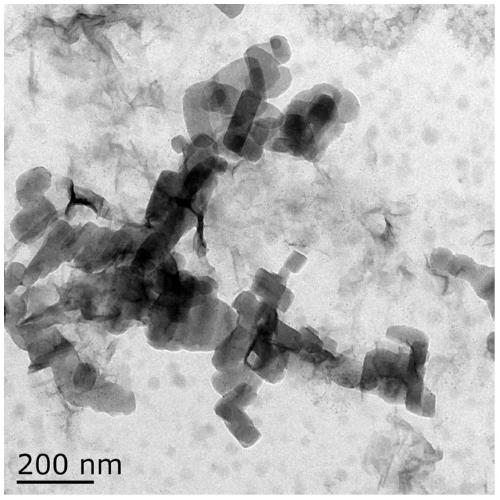

[0046] 1) Preparation of pigment and charge agent dispersion: add 5 parts of blue pigment PB15:3, 2 parts of charge regulator, 1 part of TX-100, 0.25 part of SDS into 500 parts of deionized water, and disperse evenly by ultrasonic;

[0047] Add the above mixture into a ball mill tank containing zirconia microspheres with a particle size of 1.0mm-1.6mm, the mass of the microspheres is 500 parts, and the ball mill is used to obtain a uniform and stable dispersion of pigment and charge regulator; add 200 parts to remove Deionized water is stirred and diluted;

[0048] 2) Preparation of resin-coated pigment and charge agent composite latex particles: Weigh 40 parts of styrene and 10 parts of butyl acrylate, mix them and drop them into the diluted dispersion over 30 minutes, dissolve 1.5 parts of water-soluble initiator KPS In 200 parts of deionized water, drop it in after the addition of the monomer is completed, and heat it to 75±5°C; react for 6 hours to obtain a multi-component...

Embodiment 2

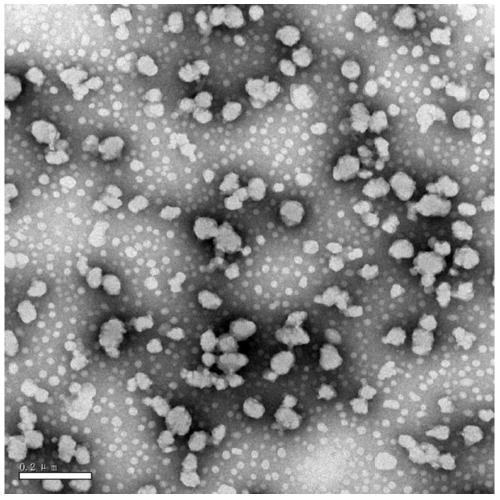

[0055] 1) Preparation of pigment and charge agent dispersion: Add 4 parts of yellow pigment PY17, 1.5 parts of charge regulator, 2 parts of TX-100, 0.5 part of SDBS into 500 parts of deionized water, and disperse evenly by ultrasonic;

[0056] Add the above mixture into a ball mill tank filled with zirconia microspheres with a particle size of 1.0mm-1.6mm. The mass of the microspheres is 400 parts. The ball mill is used to obtain a uniform and stable dispersion of pigments and charge regulators. Add 200 parts to remove Deionized water is stirred and diluted;

[0057] 2) Preparation of resin-coated pigment and charge agent composite latex particles: Weigh 37.5 parts of styrene and 12.5 parts of butyl acrylate, mix the two, drop the diluted dispersion in 30 minutes, and dissolve 1.5 parts of water-soluble initiator APS In 200 parts of deionized water, drop it in after the addition of the monomer is completed, and heat to 75±5°C after the addition;

[0058] React for 6h to obtai...

Embodiment 3

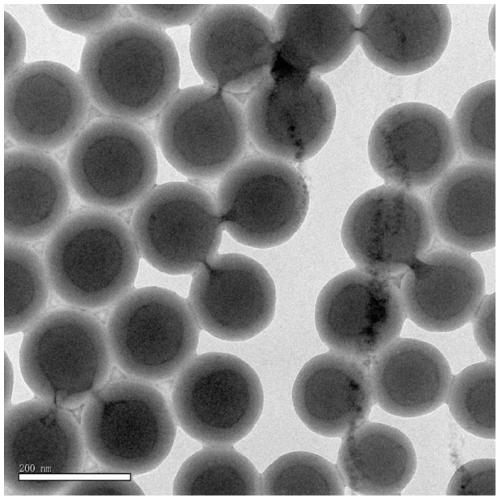

[0064] 1) Preparation of pigment and charge agent dispersion: add 3 parts of red pigment PR184, 1 part of charge regulator, 1 part of TX-100, 0.25 part of SDS into 500 parts of deionized water, and disperse evenly by ultrasonic;

[0065] Add the above mixture into a ball mill tank filled with zirconia microspheres with a particle size of 1.0mm-1.6mm. The mass of the microspheres is 500 parts. The ball mill is used to obtain a uniform and stable dispersion of pigments and charge regulators. Add 400 parts to remove Deionized water is stirred and diluted;

[0066] 2) Preparation of resin-coated pigment and charge agent composite latex particles: Weigh 35 parts of styrene and 15 parts of butyl acrylate, mix and drop into the diluted dispersion for 30 minutes, and dissolve 1 part of water-soluble initiator KPS in 200 parts of deionized water, drop it in after the addition of the monomer, and heat it to 75±5°C; react for 6 hours to obtain a multi-component composite latex particle e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com