Environment-friendly mercury-free catalyst for synthesizing vinyl chloride and preparation method thereof

A mercury catalyst and vinyl chloride technology, which is applied in the field of mercury-free catalysts and their preparation, can solve the problems that industrial application has not yet been realized, and the development and growth of calcium carbide method PVC production enterprises are restricted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

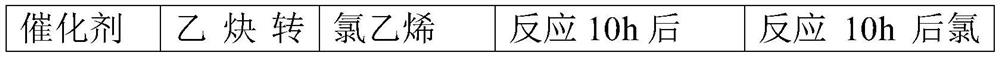

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of mercury-free catalyst, and preparation method comprises the following steps:

[0033] Weigh 7.44g of activated carbon, soak it in 3.0mol / L hydrochloric acid solution for 12h, then filter the activated carbon with suction, and dry at 105°C for 16h;

[0034] Accurately weigh the quality of the three metal salts of copper chloride, stannous chloride and platinum chloride, so that the weight ratio of the prepared catalyst is: 21.2% of cupric chloride, 4.4% of stannous chloride, and 0.03% of platinum chloride %, added to water in turn, and configured in the tank to obtain a mixed metal salt solution;

[0035] Load the metal salt solution obtained in step 1) onto the treated activated carbon by using an equal volume impregnation method at room temperature, the impregnation time is 24h, and the impregnation pressure is 2.5MPa;

[0036] After impregnation, the catalyst was transferred to a drying tower, sealed and sealed, and heated fo...

Embodiment 2

[0038] The present embodiment provides a kind of mercury-free catalyst, and preparation method comprises the following steps:

[0039] Weigh 7.20g of activated carbon, soak it in 3.0mol / L hydrochloric acid solution for 15h, then filter the activated carbon with suction and dry at 110°C for 24h;

[0040] Accurately weigh the quality of the three metal salts of copper chloride, stannous chloride and platinum chloride, so that the weight ratio of the prepared catalyst is: 19.1% of cupric chloride, 8.8% of stannous chloride, and 0.07% of platinum chloride %, added to water in turn, and configured in the tank to obtain a mixed metal salt solution;

[0041] Load the metal salt solution obtained in step 1) onto the treated activated carbon by using an equal volume impregnation method at room temperature, the impregnation time is 24 hours, and the impregnation pressure is 3.0 MPa;

[0042] After impregnation, the catalyst was transferred to a drying tower, sealed and sealed, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com