Porous polymers for the abatement and purification of electronic gas and the removal of mercury from hydrocarbon streams

An electronic gas and effluent technology, applied to compounds of group 4/14 elements of the periodic table, organic compounds of group 4/14 without C-metal bonds, electrical components, etc., can solve irregular porosity obstacles, porous Issues such as low material porosity, poor customizability limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] There is generally a strong desire for purification and reduction to maximize the flow rate and concentration of the gas stream while maintaining or reducing the size of the adsorption system.

[0022] Therefore, it would be a significant advancement in the art to provide a high-performance porous material for effectively reducing electron gas from an effluent containing electron gas. It would also be advantageous to provide high-efficiency porous materials for effectively removing contaminants from the electron gas stream. It would also be advantageous to provide high-efficiency porous materials for removing mercury from hydrocarbon gas streams.

[0023] Much research in the past few years has focused on the synthesis and characterization of microporous materials with high internal surface area, which is a measure of internal porosity.

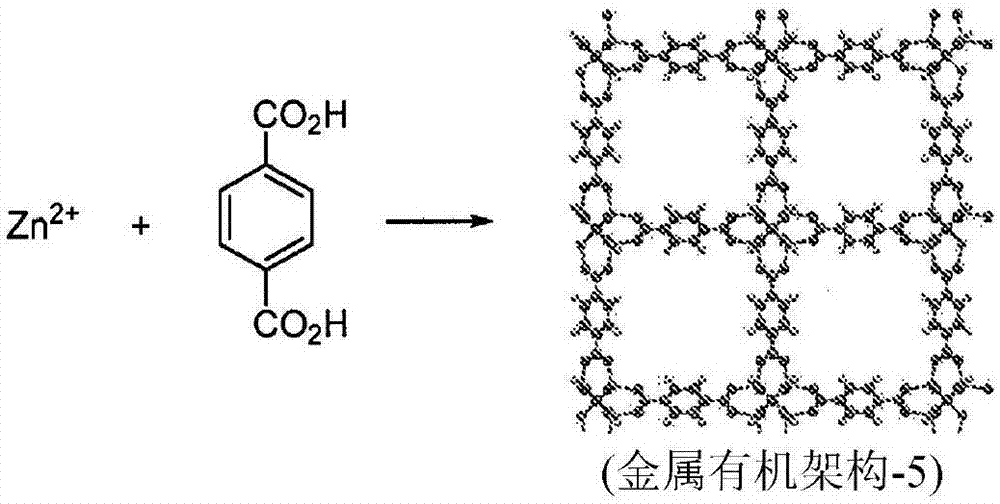

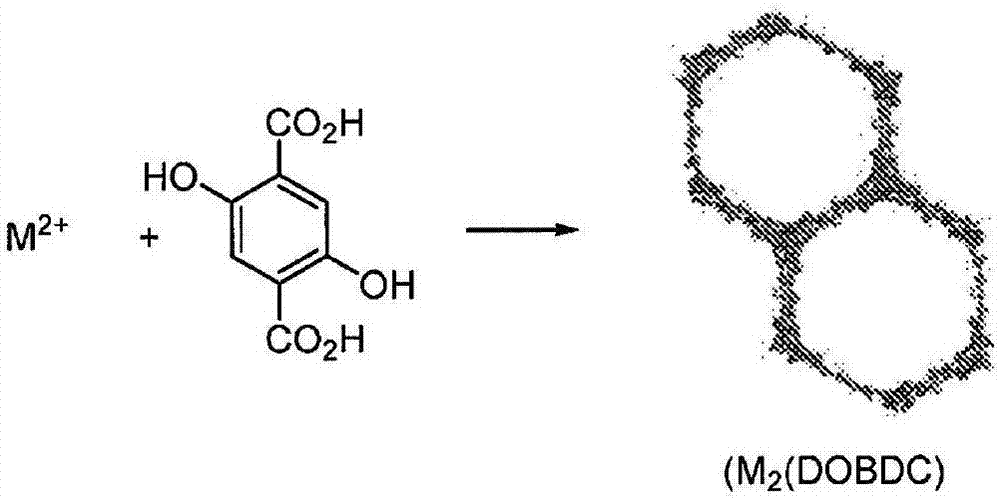

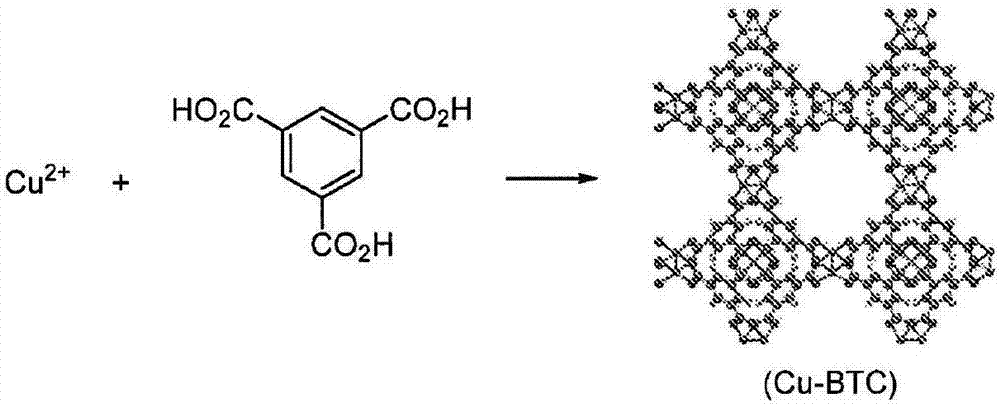

[0024] Metal organic framework (MOF) (a crystalline subset of microporous materials) has shown promise for a wide range of applications fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com