Mercury-polluted water treatment process

A water treatment and mercury pollution technology, applied in the direction of adsorption water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve industrial sewage pollution, there is no mature engineering practice precedent, and the mercury content index is very low Difficult to meet emission standards and other issues, to achieve the effect of simple process and complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

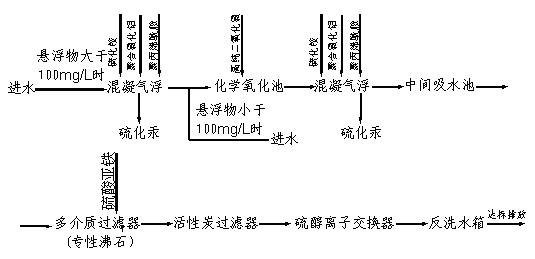

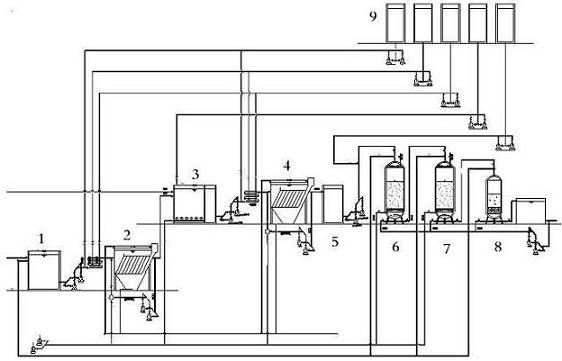

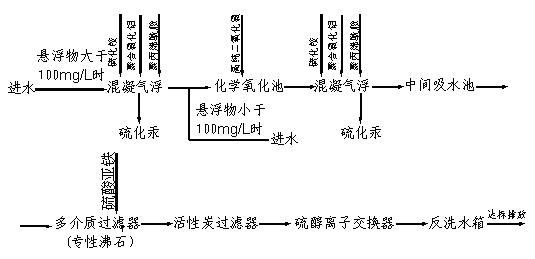

[0027] Mercury polluted water treatment process mainly includes pretreatment and mercury removal.

[0028] Pretreatment: The existing polluted water is mixed, and the mixed polluted water is sent into the suction tank 1 by the lifting pump for sewage treatment. First, after data analysis and field water sample measurement, the maximum concentration of total mercury in the mixed solution is 12522 ng / L, based on this concentration to determine the segmental control index of this set of sewage treatment process.

[0029] For the mixed polluted water, according to the content of suspended solids and organic matter in the water, different pretreatment processes are adopted to prevent the treatment device from being blocked by suspended solids during operation.

[0030] 1) When the concentration of suspended solids in the water body is less than or equal to 100mg / L, the water body is directly sent to the oxidation tank 3 water treatment system for mercury removal treatment after bei...

Embodiment 2

[0052] Mercury polluted water treatment process mainly includes pretreatment and mercury removal.

[0053] Pretreatment: with embodiment 1.

[0054] Mercury removal: It has been tested that both organic mercury and inorganic mercury are contained in the water body. The organic mercury must be removed first, and then the inorganic mercury should be removed.

[0055] Removal of organic mercury: The main method used to remove organic mercury in polluted water is to oxidize organic mercury forcibly, convert organic mercury into inorganic mercury, and then treat it according to the treatment method of inorganic mercury.

[0056] Since the water body in the on-site sedimentation tank is in a non-flowing state, the amount of suspended solids in the upper part of the pool is very low. When the concentration of suspended solids is ≤100mg / L, the water body is directly sent to the oxidation tank after being lifted, and the organic mercury, The organic matter is oxidized, and the oxidant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com