A film layer analysis method of electroluminescence device

An electroluminescent device and analysis method technology, which is applied in the direction of electric solid-state devices, material analysis and material analysis by electromagnetic means, can solve the problem of incomplete stripping of the cathode layer and the luminescent material layer, and achieve a stable and controllable stripping process. Avoid the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

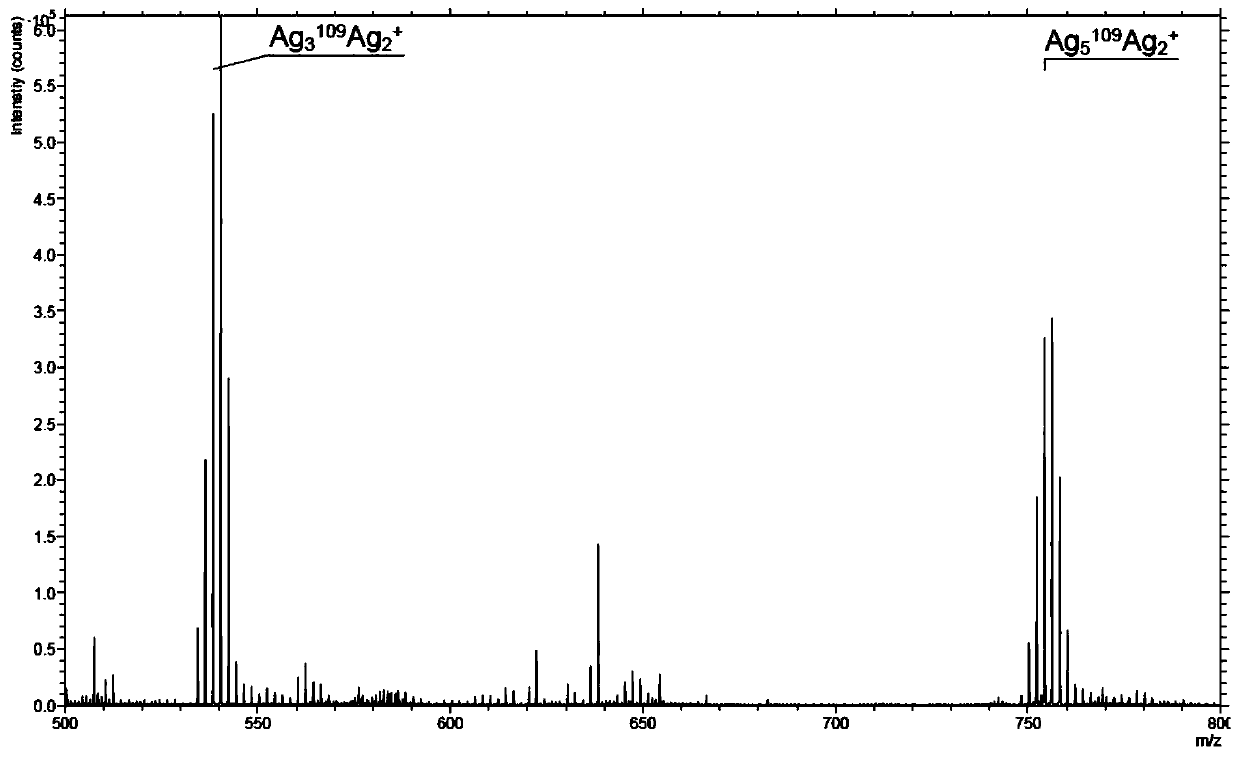

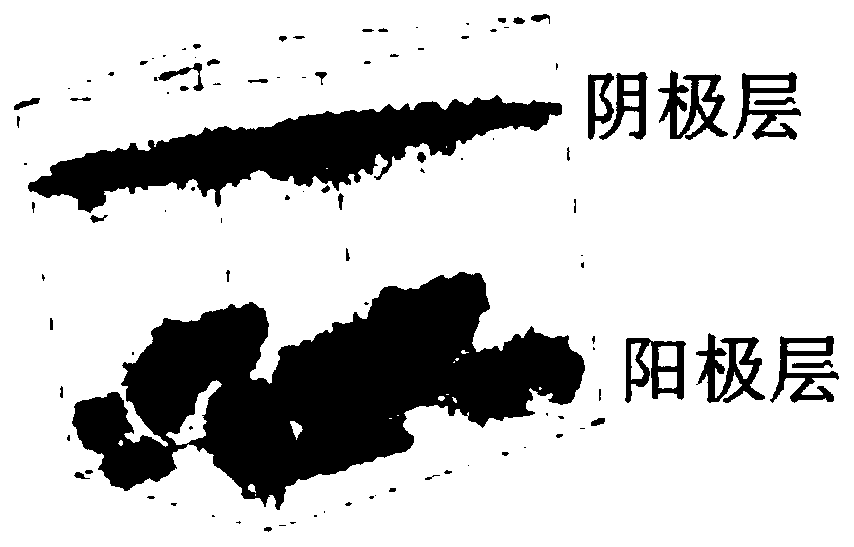

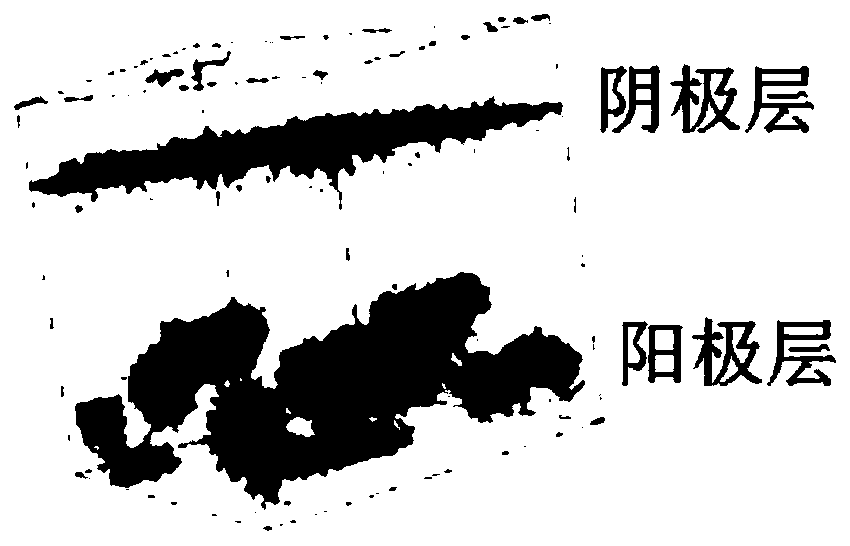

[0042] When analyzing the film layer of an electroluminescent device in the prior art, when the cathode layer needs to be peeled off by a blade or an adhesive tape, the technical problem that the cathode layer is not completely peeled off or the electroluminescent material layer is partially peeled off easily occurs, the present invention implements The example provides a film layer analysis method of an electroluminescent device, which can effectively and completely remove the silver-containing cathode layer without affecting the electroluminescent material layer.

[0043] The electroluminescent device involved in the embodiment of the present invention includes: an anode layer, an electroluminescent material layer, and a silver-containing cathode laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com