Method suitable for controlling mercury contamination in coal-fired power plants adopting wet-process flue gas desulfurization

A technology of coal-fired power plants and control methods, applied in the field of mercury pollution control, can solve the problems of secondary pollution, re-release, instability, etc., and achieve the effects of short delay, long delay and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

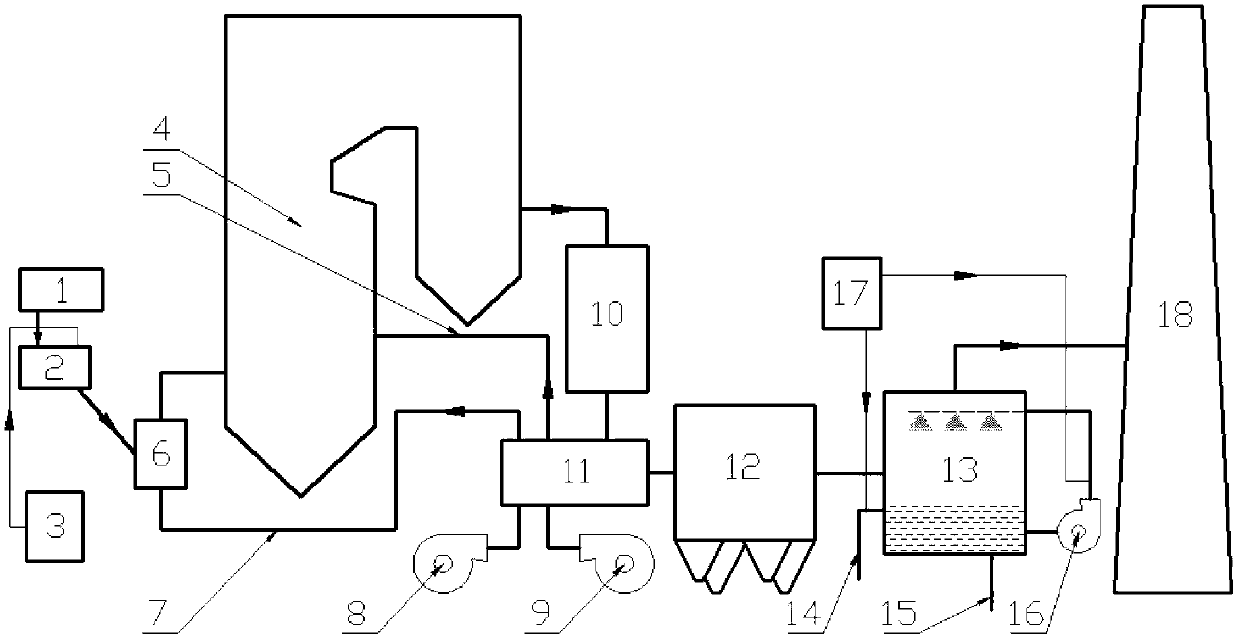

[0037] Such as figure 1 As shown, the mercury pollution control method suitable for coal-fired power plants equipped with wet flue gas desulfurization systems, the halide additive liquid storage tank 3 is connected with the coal feeder 2, and the coal feeder 2 is connected with the coal mill 6; The sulfur-containing additive storage tank 17 is connected with the outlet of the fresh slurry pipeline 14 and the circulating pump 16 . The method for realizing mercury pollution control is as follows: calcium bromide is selected as the halide additive, and after being prepared into a uniform solution of 4mol / L, it is added to the coal feeder 2, and then brought into the boiler body through the coal mill 4 Participate in combustion to promote the oxidation of mercury in the flue gas; the sulfur-containing additive used is selected from sodium hydrosulfide, and after being formulated into a uniform solution of 0.1mol / L, it is added to the fresh slurry pipeline 14 and the circulation pu...

Embodiment 2

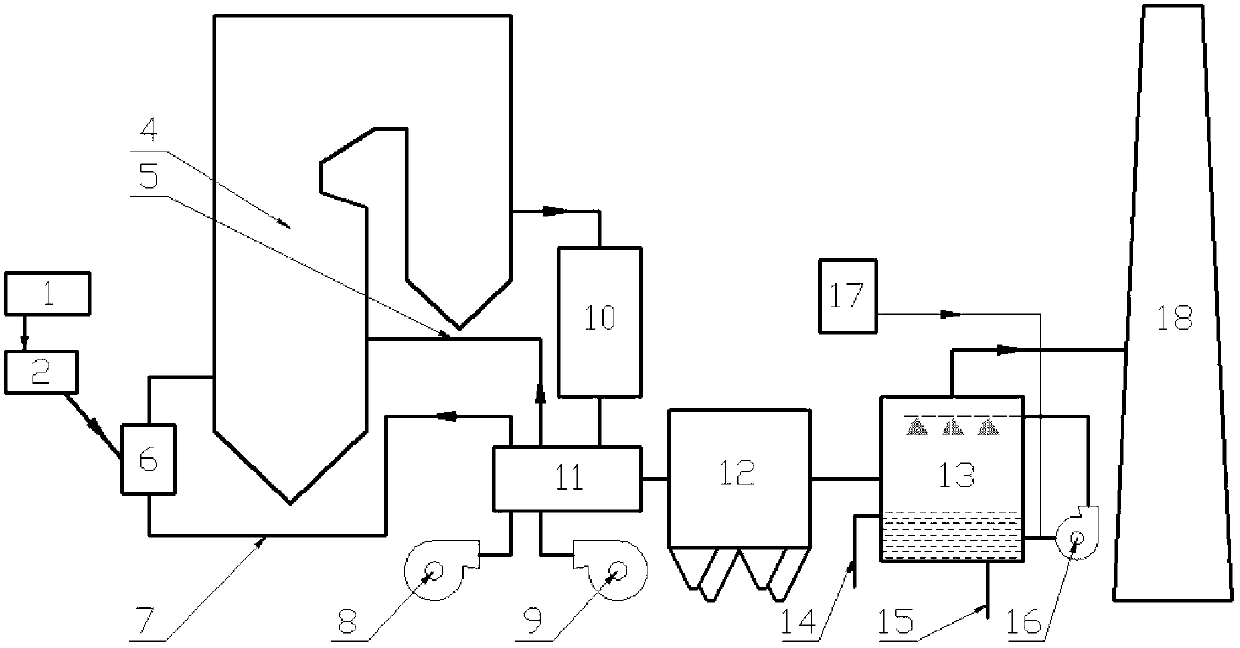

[0040] Such as figure 2 As shown, the mercury pollution control method is suitable for a coal-fired power plant equipped with a wet flue gas desulfurization system, and the sulfur-containing additive liquid storage tank 17 is connected to the inlet of the circulation pump 16 . The method for realizing mercury pollution control is as follows: the sulfur-containing additive used is selected from sodium sulfide, and after being formulated into a uniform solution of 0.2mol / L, it is added to the inlet of the circulation pump 16, so as to be compatible with the circulating slurry and the flue gas. The mercury oxide reacts to form stable mercury sulfide precipitation, thereby ensuring the effective removal of mercury oxide and making the mercury content in the flue gas in the chimney 18 meet the emission requirements. The ratio of the amount of sodium sulfide added to the amount of standard flue gas is 1×10 -5 g / Nm 3 .

[0041] In this example, by adding sodium sulfide additive i...

Embodiment 3

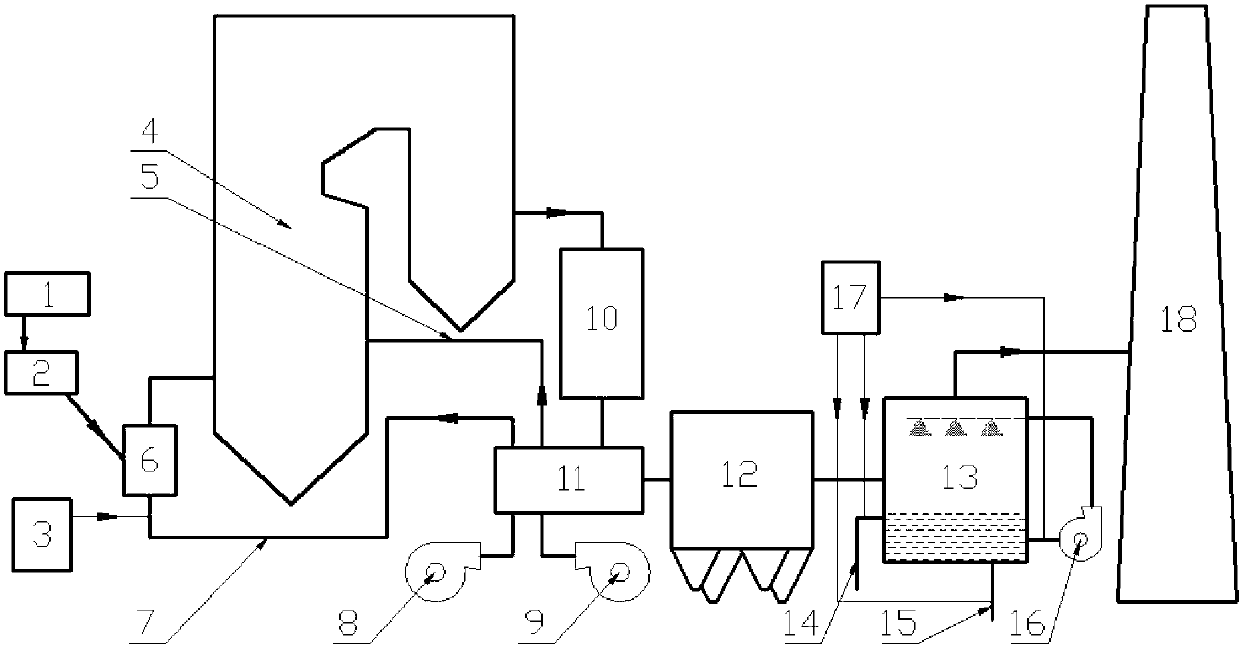

[0043] Such as image 3 As shown, the mercury pollution control method is suitable for coal-fired power plants equipped with wet flue gas desulfurization systems. Connection; the sulfur-containing additive liquid storage tank 17 is connected with the outlet of the fresh slurry pipeline 14, the desulfurization waste liquid pipeline 15 and the circulating pump 16. The method for realizing mercury pollution control is as follows: the halide additive used is a mixed solution of calcium bromide and calcium chloride, the concentration of calcium bromide is 3mol / L, and the concentration of calcium chloride is 5mol / L. The liquid tank 3 is added to the primary air hot air pipeline 7, and the primary air is brought into the boiler body 4 to participate in combustion, which promotes the oxidation of mercury in the flue gas; the sulfur-containing additive used is selected from organic sulfur (TMT15), and is formulated to be 0.05 mol / L uniform solution, it is added to the fresh slurry pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com