Method for consolidating waste incineration fly ash heavy metal through microorganism cement mineralization

A technology for waste incineration fly ash and microbial cement, which is applied in the field of environmental engineering, can solve the problems of the influence of cement consolidation and hardening time, reduce fly ash strength, and high cement consumption, so as to improve the consolidation efficiency of heavy metals and avoid secondary Environmental pollution, the effect of low metal leaching concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

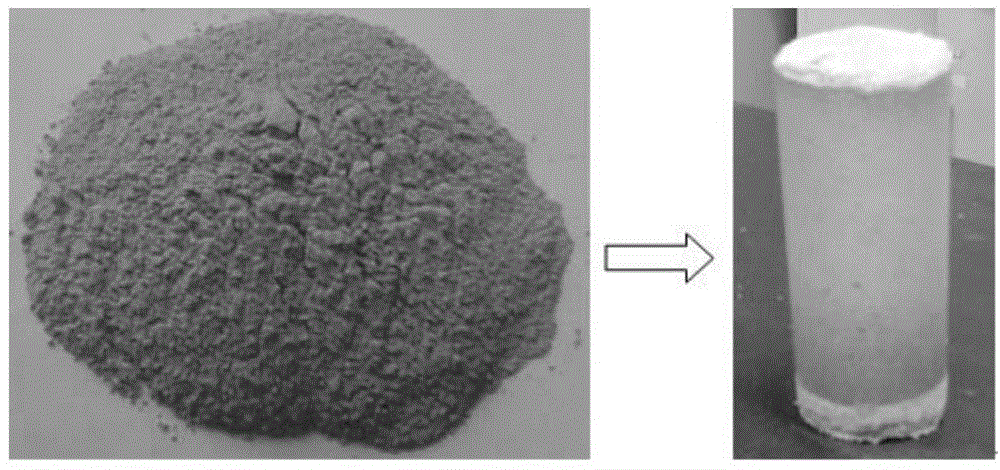

Image

Examples

Embodiment 1

[0028] The leaching concentrations of the typical heavy metals Pb, Zn, Cu, Cd and Cr in pure water were 9.34mg / L, 118.51mg / L, 167.34mg / L, respectively. L, 1.14mg / L and 25.54mg / L.

[0029] 1. First prepare the microbial cement cement calcite:

[0030] Inoculate Bacillus pasteurianus into the mixed medium of soybean peptone and casein peptone, the medium contains 3-7g of soybean peptone and 13-15g of casein peptone per liter; control the pH at 6-8, at 30-37°C, the speed is 160 Under ~180r / min, cultivate for 16 ~ 24 hours to get Bacillus pasteurian bacteria liquid.

[0031] Separately, 180 grams of urea, 333 grams of calcium chloride, 600 grams of calcium bromide, and 495 grams of calcium nitrate were dissolved in 3 liters of water and mixed to obtain a 1 mol / L urea-calcium source mixed solution.

[0032] Take 0.5 liters of the Bacillus pasteurian bacteria liquid and 1 mol / L urea-calcium source mixed solution, mix them, and stir them evenly to obtain microbial cement. The obta...

Embodiment 2

[0036] The leaching concentrations of typical heavy metals Pb, Zn, Cu, Cd and Cr in pure water from waste incineration fly ash collected from a coal-fired power plant were 7.24mg / L, 112.11mg / L, 137.14mg / L, 1.43mg / L and 18.97mg / L.

[0037] Microbial cement cementitious material calcite was prepared according to Example 1.

[0038] Take 16g of calcite, 40g of waste incineration fly ash, 40g of water, and then mix the calcite and waste incineration fly ash evenly, maintain at 25°C for 5 days, demould, and dry.

[0039] Test its compressive strength, the result is 2.7MPa. The leaching concentration of typical heavy metals in pure water was tested by the horizontal oscillation method. They were 1.52mg / L, 38.82mg / L, 32.78mg / L, 0.62mg / L and 10.91mg / L respectively, which were all lower than my country's "Dangerous The standard limits specified in the Waste Leaching Toxicity Standard.

Embodiment 3

[0041] The leaching concentrations of typical heavy metals Pb, Zn, Cu, Cd and Cr in pure water from waste incineration fly ash collected from a coal-fired power plant were 8.48mg / L, 115.43mg / L, 142.36mg / L, 1.62mg / L and 28.68mg / L.

[0042] Microbial cement cementitious material calcite was prepared according to Example 1.

[0043] Weigh 24g of calcite, 40g of waste incineration fly ash, and 50g of water, and then mix the calcite and waste incineration fly ash evenly, maintain at 25°C for 7 days, demould, and dry.

[0044] Test its compressive strength, the result is 3.3MPa. The leaching concentration of typical heavy metals in pure water was tested by the horizontal oscillation method. They were 1.21mg / L, 37.24mg / L, 28.98mg / L, 0.72mg / L and 11.23mg / L respectively, which were all lower than my country's "Dangerous The standard limits specified in the Waste Leaching Toxicity Standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com