Low-sulfur chromium contaminated soil remediation agent, preparation method and use method thereof

A technology for chromium-contaminated soil and remediation agent, applied in the field of soil pollution control, can solve problems such as site water and soil acidification, building base corrosion, secondary pollution, etc., to promote reducing ability, maintain structure and acid-base balance, and reduce hexavalent Effects of Chromium Toxicity Leaching Degree and Alkali Digestion Leaching Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

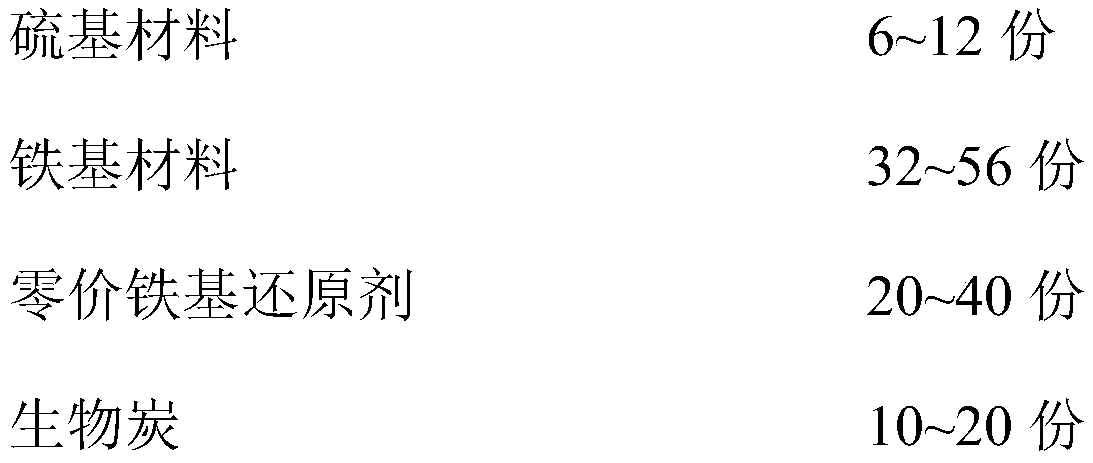

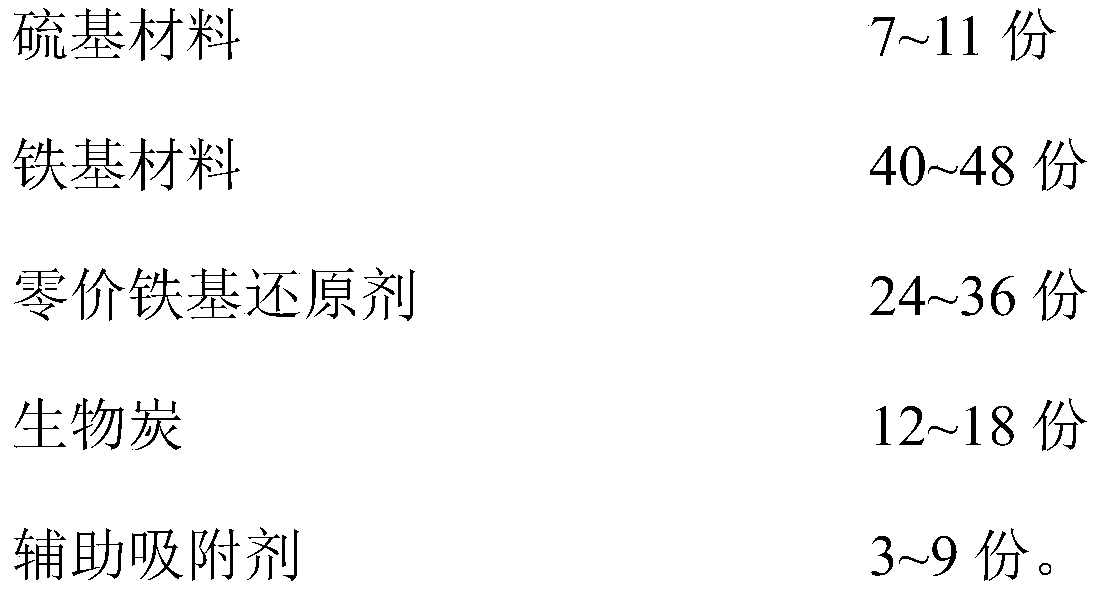

[0079] The preparation of a low-sulfur type chromium-contaminated soil remediation agent comprises:

[0080]In this embodiment, the sulfur-based material is a pore structure iron-based sulfate mineral with a porosity of 20wt%, a sulfur content of 6wt%, and an iron content of 15wt%. The preparation process of the pore structure iron-based sulfate mineral is The method comprises: dissolving ferrous chloride in sodium sulfate solution at a molar ratio of 1:1, passing through ozone for oxidation to obtain a sulfur-based material; the iron-based material is iron-aluminum hydrotalcite with an iron element content of 60 wt%. .

[0081] Grinding 8g of sulfur-based material to 200 mesh as component A; mixing 42g of iron-based material, 30g of micron iron powder, 15g of wheat bran and 5g of mordenite, both of which have a particle size of 200 mesh , ground to the average particle size of the mixture is 1mm, as the B component, to obtain the soil remediation agent;

[0082] Use this so...

Embodiment 2

[0086] The difference from Example 1 is that the mass of the sulfur-based material in component A is 12 g, and the mass of the iron-based material in component B is 38 g. After the soil is repaired, the soil is tested in the same manner as in Example 1. It was detected that the leaching concentration of hexavalent chromium in the soil sample was reduced from 261.68 mg / L to 0.25 mg / L, and the total amount of hexavalent chromium by alkali digestion was reduced from 2310.61 mg / kg to 6.21 mg / kg.

Embodiment 3

[0088] The difference from Example 1 is that the mass of the sulfur-based material in the A component is 6g, and the mass of the iron-based material in the B component is 44g. After the soil is repaired, the soil is tested in the same manner as in Example 1. It was detected that the leaching concentration of hexavalent chromium in the soil sample decreased from 261.68 mg / L to 0.42 mg / L, and the total amount of hexavalent chromium by alkali digestion decreased from 2310.61 mg / kg to 8.87 mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com