Cement filling material for co-solidifying arsenic and preparation method thereof

A technology of filling and cementing, which is applied in the field of cemented filling for coordinating hazardous arsenic-containing wastes in mines and its preparation, can solve the problems of complex mining and filling processes, low production efficiency and capacity, and high energy consumption in the production process. Avoid polluting groundwater, low cost, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

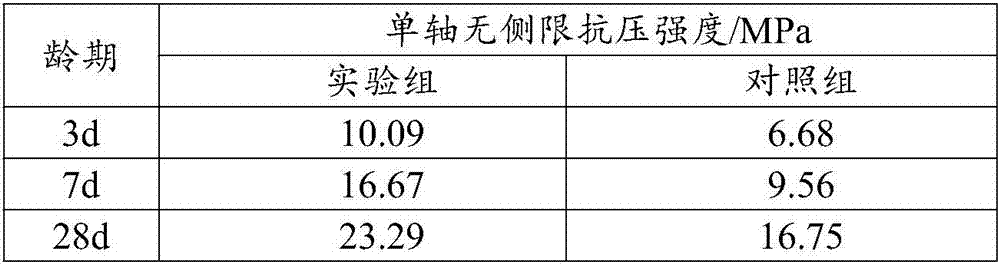

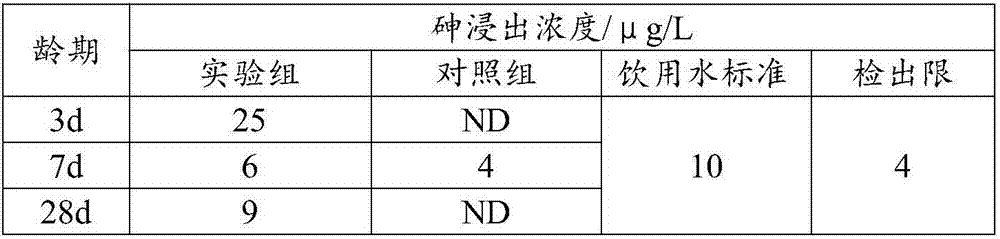

Examples

Embodiment 1

[0043] A cementing material for mines, prepared from the following raw materials in weight percentage:

[0044] Slag 60%

[0045] Steel slag 30%

[0046] Desulfurization gypsum 10%

[0047] A method for preparing cemented fillers for mines for the co-processing of arsenic-containing hazardous wastes, which is characterized in that: the cementing agent after grinding treatment is mixed with aggregates, arsenic-containing hazardous wastes, and water reducing agents, and water is evenly mixed, Specific steps are as follows:

[0048] (1) Dry the required raw material slag, steel slag, and desulfurized gypsum to a moisture content of 0.01% to 1% respectively, and then separate the slag, steel slag, and desulfurized gypsum at 60%, 30%, and 10% by weight on a dry basis. Grind to a specific surface area of 400m 2 / Kg、400m 2 / Kg、360m 2 / Kg mixing to obtain cementing agent;

[0049] (2) Disposal of hazardous waste containing arsenic is lead-zinc mine tailings, which are also used as aggregates...

Embodiment 2

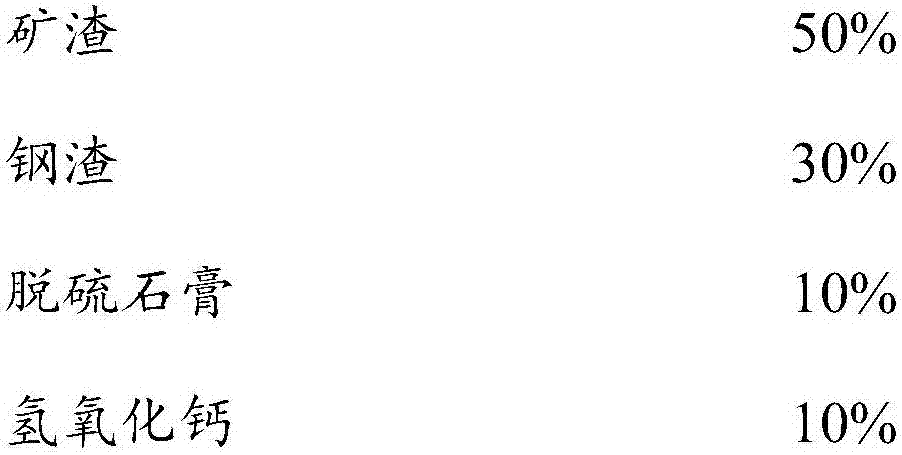

[0062] A gelling agent for mines, prepared from the following raw materials by weight percentage:

[0063]

[0064] A method for preparing cemented fillers for mines for the co-processing of arsenic-containing hazardous wastes, which is characterized in that: the cementing agent after grinding treatment is mixed with aggregates, arsenic-containing hazardous wastes, and water reducing agents, and water is evenly mixed, Specific steps are as follows:

[0065] (1) Dry the required raw material slag, steel slag, and desulfurized gypsum to a moisture content of 0.01% to 1%, and then separately grind the slag, steel slag, and desulfurized gypsum to a specific surface area of 400m 2 / Kg、400m 2 / Kg、360m 2 / Kg, the cementing agent is prepared by mixing 50%, 30%, 10% and 10% of analytically pure calcium hydroxide according to the weight percentage of dry basis;

[0066] (2) Hazardous waste containing arsenic is lead-zinc ore tailings, which is also used as aggregate. It is dried to a moistur...

Embodiment 3

[0080] A gelling agent for mines, prepared from the following raw materials by weight percentage:

[0081]

[0082] A method for preparing cemented fillers for mines for the co-processing of arsenic-containing hazardous wastes, which is characterized in that: the cementing agent after grinding treatment is mixed with aggregates, arsenic-containing hazardous wastes, and water reducing agents, and water is evenly mixed, Specific steps are as follows:

[0083] (1) Dry the required raw materials slag, steel slag, and desulfurized gypsum to a moisture content of 0.01% to 1%, and then separate the slag, steel slag, and desulfurized gypsum at 45%, 10%, and 10% by weight on a dry basis. Grind to specific surface area 435m 2 / Kg、444m 2 / Kg、360m 2 / Kg, mixed with 35% calcium hydroxide on a dry basis to obtain a cementing agent;

[0084] (2) Dry the arsenic-containing hazardous waste to a moisture content of 0.01% to 1%, and add 1% polycarboxylic acid water reducing agent to the weight ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com