Method for preparing haydite from sludge incineration ash in chemical industry

A technology for chemical sludge and incineration ash, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., to achieve the effect of easy industrialization, good environmental and social benefits, and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dry the remaining sludge with a mass moisture content of 75% at 110°C for 8 hours, incinerate the dried sludge at 1200°C for 30 minutes, grind it, and pass it through a 30-mesh sieve; take 50g of sludge incineration ash, clay 18g, 30g of fly ash, and 2g of aluminum powder were respectively put into the mixing basin, fully stirred and mixed, and water was added to control the mass moisture content to 10%; after mixing, granulated to obtain raw meal balls; after drying at 80°C for 12 hours, control The heating rate is 15°C / min, and it is sintered at 1050°C for 15 minutes to obtain ceramsite. After testing, its bulk density is 0.65g / cm 3 , the cylinder compressive strength is 3.1MPa, and the heavy metal leaching test results are shown in Table 1.

Embodiment 2

[0028] Dry the remaining sludge with a mass moisture content of 85% at 120°C for 6 hours, incinerate the dried sludge at 1250°C for 10 minutes, grind it, and pass it through a 60-mesh sieve; Put 39g of clay and 1g of aluminum powder into the mixing basin respectively, stir and mix well, add water to control the moisture content of the mass to 15%, granulate after mixing, and obtain raw meal balls; after drying at 100°C for 6 hours, control the heating rate to 25°C / min, sintered at 1100°C for 12 minutes to obtain ceramsite. After testing, its bulk density is 0.73g / cm 3 , the cylinder compressive strength is 3.5MPa, and the heavy metal leaching test results are shown in Table 1.

Embodiment 3

[0030] Dry the remaining sludge with a mass moisture content of 85% at 105°C for 24 hours, incinerate the dried sludge at 1250°C for 20 minutes, grind it, and pass it through a 100-mesh sieve; take 55g of sludge incineration ash, clay 19.5g, 25g of fly ash, and 0.5g of aluminum powder were respectively put into the mixing basin, fully stirred and mixed, and water was added to control the moisture content to 8%; after mixing, granulated to obtain raw meal balls; after drying at 105°C for 4 hours, Control the heating rate to 30°C / min, and sinter at 1150°C for 10 minutes to obtain ceramsite. After testing, its bulk density is 0.8g / cm 3 , the cylinder compressive strength is 4.0MPa, and the heavy metal leaching test results are shown in Table 1.

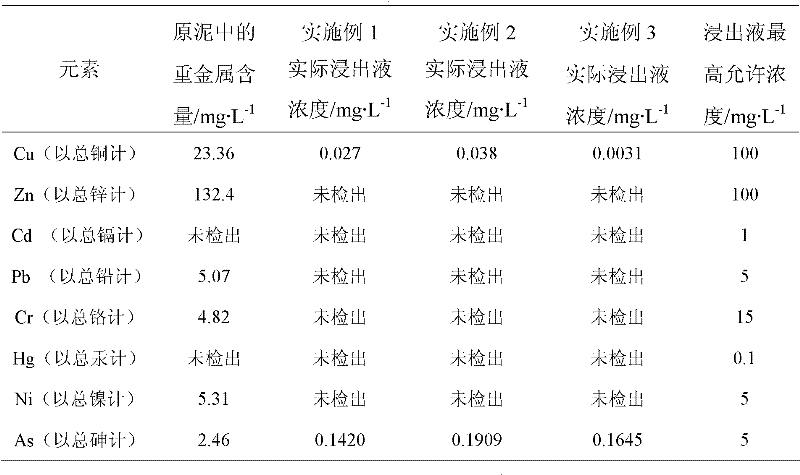

[0031] Table 1 Analysis of heavy metal content in leaching solution of ceramsite leaching toxicity identification test

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com