Method for preparing ceramsite from industrial sludge, waste incineration fly ash and straw as raw materials

A technology for waste incineration fly ash and industrial sludge, which is applied in applications, household utensils, clay products, etc. It can solve the problems of expensive treatment and disposal, large landfill or composting area, secondary pollution, etc., and achieve good economy and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

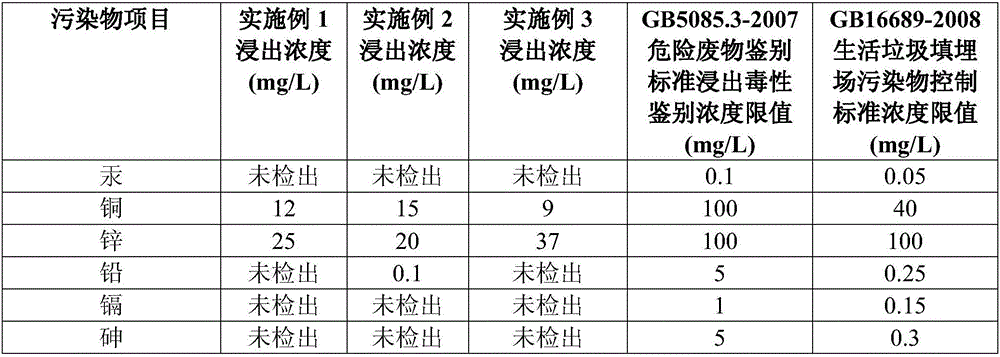

[0030] Get 45kg of industrial sludge, 20kg of waste incineration fly ash, 10kg of sodium-based bentonite, 5kg of straw powder, and 5kg of clay. After mixing evenly, add 10% (mass ratio) of water, and fully stir to form a 5-10mm spherical ceramsite raw meal. Then continue to add 5% sodium-based bentonite, 4% straw powder, and a total of 1% water glass and calcium lignosulfonate mixed binder, fully stir and carry out secondary granulation to form spherical ceramsite of 8-15mm The raw material is calcined at 1350°C for 20 minutes in a rotary kiln, and then cooled naturally to obtain lightweight ceramsite. The generated ceramsite has passed the heavy metal leaching toxicity test and is far lower than the concentration limit of GB5085.3-2007 hazardous waste identification standard leaching toxicity identification and GB16689-2008 domestic waste landfill pollutant control standard concentration limit.

Embodiment 2

[0032] Get 30kg of industrial sludge, 15kg of waste incineration fly ash, 15kg of sodium-based bentonite, 5kg of straw powder, and 5kg of clay. After mixing evenly, add 10% (mass ratio) of water, and fully stir to form a 5-10mm spherical ceramsite raw meal. Then continue to add 5% sodium bentonite, 4% straw powder and a total amount of 1% water glass and calcium lignosulfonate mixed adhesive, mix and then add 10% (mass ratio) of water after fully stirring Secondary granulation, shaped into 8-15mm spherical ceramsite raw material, calcined at 1350°C for 15 minutes in a rotary kiln, and naturally cooled to obtain light ceramsite. The generated ceramsite has passed the heavy metal leaching toxicity test and is far lower than the concentration limit of GB5085.3-2007 hazardous waste identification standard leaching toxicity identification and GB16689-2008 domestic waste landfill pollutant control standard concentration limit.

Embodiment 3

[0034] Get 50kg of industrial sludge, 30kg of waste incineration fly ash, 15kg of sodium-based bentonite, 5kg of straw powder, and 5kg of clay. After mixing evenly, add 10% (mass ratio) of water, and fully stir to form a 5-10mm spherical ceramsite raw meal. Then continue to add 5% sodium bentonite, 4% straw powder and a total amount of 1% water glass and calcium lignosulfonate mixed binder, mix and then add 10% (mass ratio) of water after fully stirring Secondary granulation, shaped into 8-15mm spherical ceramsite raw material, calcined at 1350°C for 25 minutes in a rotary kiln, and naturally cooled to obtain light ceramsite. The generated ceramsite has passed the heavy metal leaching toxicity test and is far lower than the concentration limit of GB5085.3-2007 hazardous waste identification standard leaching toxicity identification and GB16689-2008 domestic waste landfill pollutant control standard concentration limit.

[0035] The following table shows that the ceramsite prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com