A method for preparing ceramsite from chemical sludge

A technology for chemical sludge and drying sludge, which is applied in the production of clay products, ceramic materials, and other household appliances to achieve good environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take the remaining sludge with a mass water content of 75%, dry it at 120°C for 5 hours, take 50g of dried sludge, 13g of clay, 20g of fly ash, and 7g of heavy oil respectively, and put them into the mixing basin respectively, and after fully stirring and mixing, Add water to control the mass moisture content to 10%, stir and mix well and granulate to obtain raw meal balls; after drying at 80°C for 12 hours, heat at 400°C for 0.5h at a heating rate of 20°C / min; then heat at 15°C / min heating rate, heating up to 1150°C, holding for 10min; after cooling, ceramsite is obtained. After testing, its bulk density is 0.76g / cm 3 , the cylinder compressive strength is 4.4MPa, and the heavy metal leaching test results are shown in Table 1.

Embodiment 2

[0026] Take the remaining sludge with a mass water content of 80%, dry it at 110°C for 9 hours, take 30g of dried sludge, 15g of clay, 50g of fly ash, and 5g of heavy oil respectively, and put them into the mixing basin respectively, and after fully stirring and mixing, Add water to control the mass moisture content to 30%, stir and mix well, and then granulate to obtain raw meal balls; after drying at 100°C for 6 hours, raise the temperature to 400°C at a heating rate of 10°C / min, and keep it warm for 1 hour; Min heating rate, at 1100 ° C for 12 minutes; after cooling, ceramsite is obtained. After testing, the bulk density is 0.80g / cm 3 , the cylinder compressive strength is 4.63MPa, and the heavy metal leaching test results are shown in Table 1.

Embodiment 3

[0028] Take the remaining sludge with a mass moisture content of 85%, and dry it at 105°C for 24 hours. Take 45g of dried sludge, 15g of clay, 25g of feldspar powder, and 10g of heavy oil, respectively, and put them into the mixing basin. After fully stirring and mixing, add water , control the mass moisture content to 9%, stir and mix and granulate to obtain raw meal balls; after drying at 105°C for 4 hours, raise the temperature to 450°C at a heating rate of 15°C / min, and keep warm for 1h; then at 20°C / min Min heating rate, heating up to 1200 ℃, heat preservation 10min; after cooling, ceramsite is obtained. After testing, the bulk density is 0.5g / cm 3 , the cylinder compressive strength is 3.78MPa, and the heavy metal leaching test results are shown in Table 1.

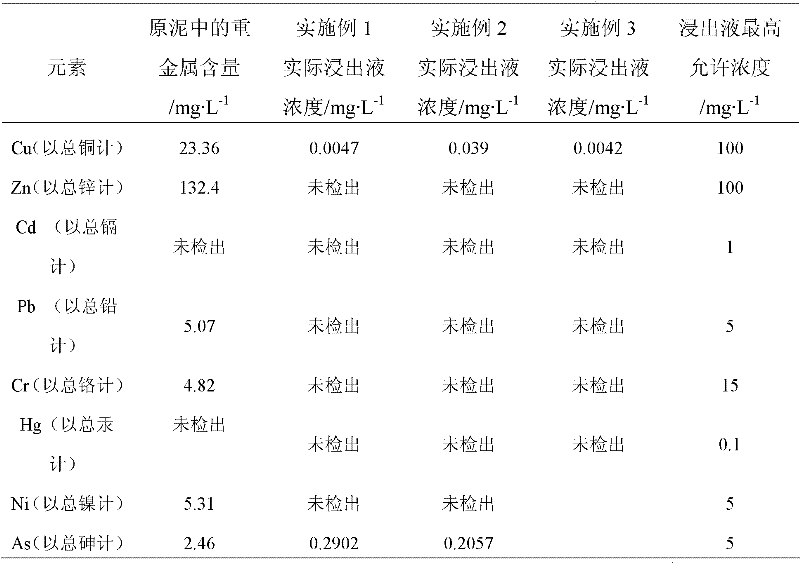

[0029] Table 1 Analysis of heavy metal content in leaching solution of ceramsite leaching toxicity identification test

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com