Method for stabilizing treatment of refuse burning fly ash by using accelerated carbonation process

A technology for waste incineration fly ash and stabilization treatment, applied in the field of hazardous solid waste treatment, can solve the problems of waste impact, lack of stabilizing agents that can be used on a large scale, and achieve the effect of harmless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

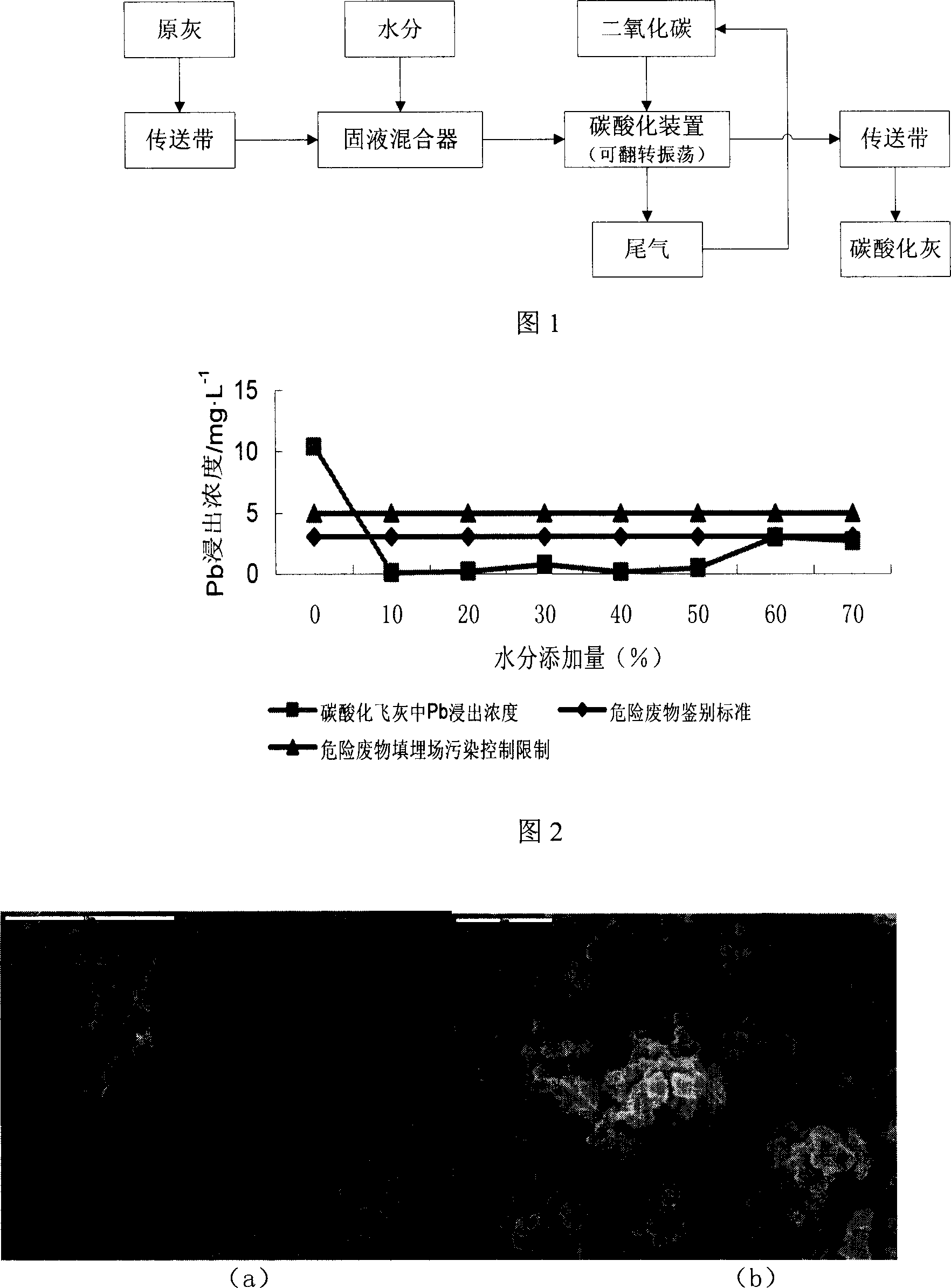

Method used

Image

Examples

Embodiment 1

[0030]The experimental material used is urban waste incineration fly ash collected by a semi-dry method in a waste incineration site in the south, with a moisture content of 3%. In order to ensure that the incineration fly ash is fresh and does not come into contact with the air for a long time, the fly ash taken during sampling is the fly ash produced on the same day. After being collected with a sealed device, the air in the sealed device is drained and stored in a cool place. Incineration fly ash samples were analyzed by XRF-1700 X-ray fluorescence spectrometer. The fly ash samples were subjected to the leaching toxicity test according to the "National Standard of the People's Republic of China for Solid Waste Leaching Toxicity Leaching Method" (GB5086.1-1997), and the concentration of heavy metals in the leachate was measured by plasma emission spectrometry (ICP).

[0031] Table 1 Changes of main chemical composition of fly ash before and after carbonation

[0032] ...

Embodiment 2

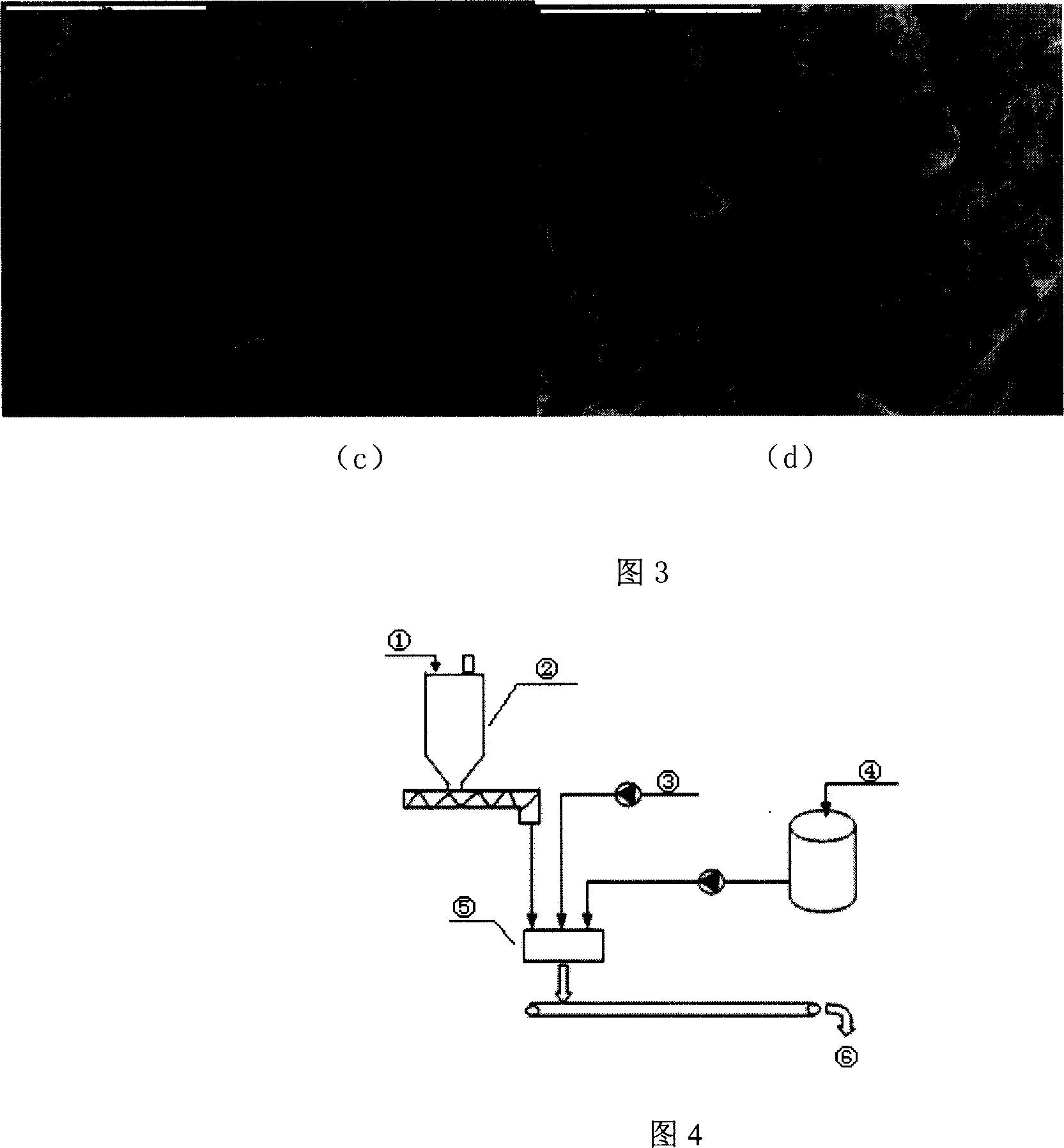

[0044] The experimental material used is municipal waste incineration fly ash collected by a semi-dry method in a waste incineration site in the south, and the leaching concentration of Pb is 12.94mg / L. in pure CO 2 Next, add 10% water, and operate and treat with a simplified device (as shown in Figure 4) for 24 hours. The concentration of Pb in the leaching solution is 0.199 mg / L, which meets the toxicity identification standard and can be safely landfilled.

Embodiment 3

[0046] The experimental material used is municipal waste incineration fly ash collected by a semi-dry method in a waste incineration site in the south, and the leaching concentration of Pb is 12.94mg / L. in pure CO 2 Next, add 20% water, and use a simplified device (as shown in Figure 4) to operate and process for 24 hours. The concentration of Pb in the leaching solution is 0.081mg / L, which meets the toxicity identification standard and can be safely landfilled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com