System and process for treating incineration fly ash through synergism of thermal desorption and carbon neutralization

A technology for incinerating fly ash and carbon neutralization, which is applied in transportation and packaging, chemical instruments and methods, and solid waste removal, etc. The effect of reducing the amount of addition and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

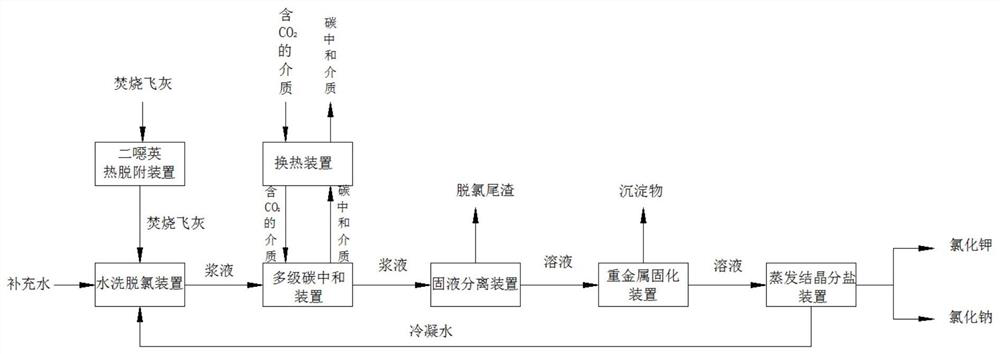

[0032] Such as figure 1 As shown, a system for thermal desorption and carbon neutralization to treat incineration fly ash, including a thermal desorption device for dioxins, a water elution chlorine removal device, a multi-stage carbon neutralization device, a solid-liquid separation device, a heavy metal solidification device, Evaporation and crystallization salt separation device and heat exchange device; the incineration fly ash outlet of the dioxin thermal desorption device is connected to the incineration fly ash inlet of the water elution chlorine removal device; the slurry outlet of the water elution chlorine removal device is connected to the multi-stage carbon neutralization device The slurry inlet connection of the multi-stage carbon neutral device containing CO 2 The medium inlet and heat exchange device containing CO 2 The medium outlet connection of the multi-stage carbon neutralization device, the carbon neutralization medium outlet of the multi-stage carbon neu...

Embodiment 2

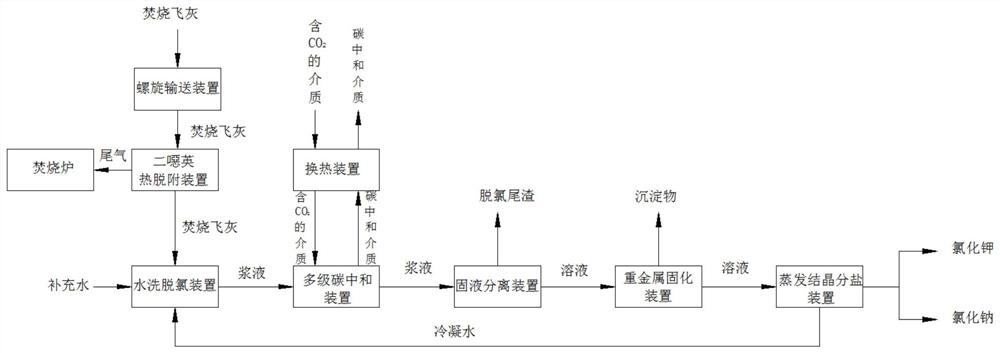

[0041] Such as figure 2 As shown, a system for thermal desorption and carbon neutralization to treat incineration fly ash, including a thermal desorption device for dioxins, a water elution chlorine removal device, a multi-stage carbon neutralization device, a solid-liquid separation device, a heavy metal solidification device, Evaporation crystallization and salt separation device, heat exchange device and incinerator;

[0042] The tail gas outlet of the dioxin thermal desorption device is connected to the tail gas inlet of the incinerator, and the incineration fly ash outlet of the dioxin thermal desorption device is connected to the incineration fly ash inlet of the water elution chlorine removal device; the slurry of the water elution chlorine removal device The outlet is connected to the slurry inlet of the multi-stage carbon neutralization device, and the CO containing 2 The medium inlet and heat exchange device containing CO 2 The medium outlet connection of the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com