Heavy-copper step circuit board and preparation method thereof

A circuit board and ladder technology, which is used in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, and printed circuits. It can solve the problems of easy scratching, low production efficiency, and long plating time, and achieve high economic Benefit, low cost, and the effect of solving the line gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 The preparation method of 3OZ thick copper stepped circuit board

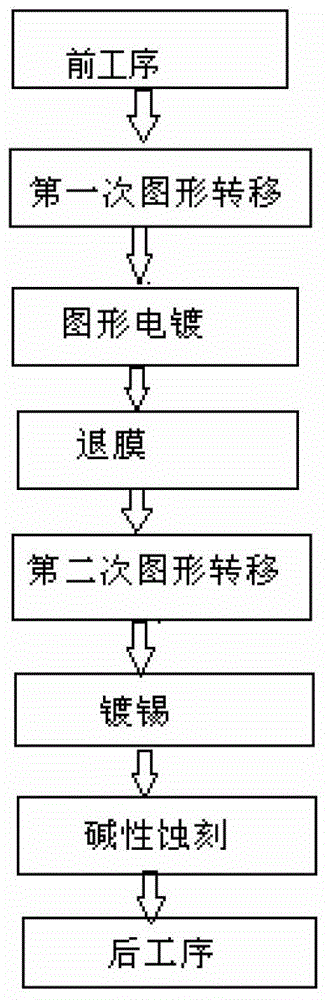

[0044] see figure 1 , is the preparation process diagram of the thick copper stepped circuit board of the present invention. In this embodiment, the thin copper lines are 1OZ and the thick copper lines are 3OZ. Prepared by the following procedure:

[0045] 1. Pre-process

[0046] That is, the copper sinking electrical process is an existing conventional technology, and will not be repeated here.

[0047] 2. The first graphics transfer

[0048] Using a positive film with only thick copper lines, the process flow is grinding plate-roller film-exposure-development;

[0049]In the next process of graphic plating for thick copper stepped circuit boards, some lines will be thickened from thin copper to thick copper lines; there is a large difference between thick and thin lines, and the use of conventional 2mil dry film in the roll film process will cause quality problems with the film cl...

Embodiment 2

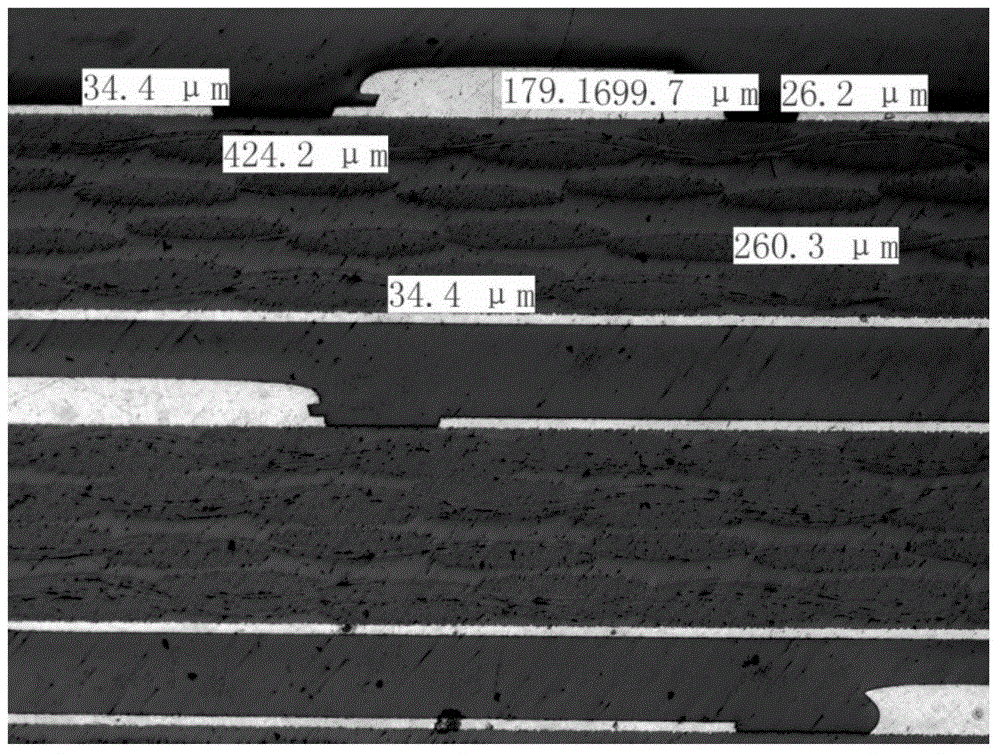

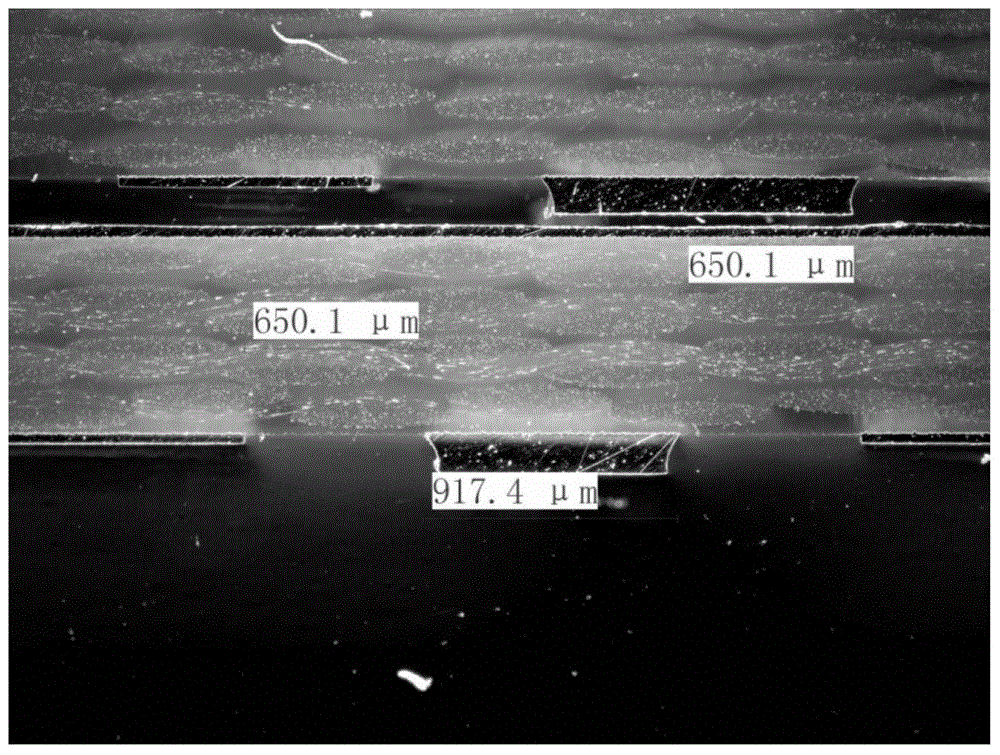

[0074] The thick copper step plate of the present embodiment is compared with the microsection of the step plate prepared by traditional technology, and the results are as follows: figure 1 and figure 2 As shown, the results show that: the stepped plate prepared by the traditional process has film clips, but the stepped plate prepared by the process of this embodiment has no film clips, therefore, the preparation method of the present invention meets the requirements. Embodiment 2 The preparation method of 3OZ thick copper stepped circuit board

[0075] The preparation method of the thick copper ladder circuit board of this embodiment is all identical with the step of embodiment 1 except that following steps are different from embodiment:

[0076] 2. The first graphics transfer

[0077] A layer of 2mil dry film is used in the rolling film process. After the plate is rolled normally, take the plate, tear off the protective film, put it into the rolling machine and roll the...

Embodiment 3

[0087] Embodiment 3 The preparation method of 6OZ ultra-thick copper stepped circuit board

[0088] In this embodiment, the thin copper lines are 1OZ and the thick copper lines are 6OZ.

[0089] The preparation method of the thick copper ladder circuit board of this embodiment is all identical with the step of embodiment 1 except that following steps are different from embodiment:

[0090] 2. The first graphics transfer

[0091] In this example, two layers of 2mil dry film are used in the roll film process. After the plate is normally rolled once, take the plate, tear off the protective film, put it into the roll machine and roll the film again; the roll plate parameters are: roll plate pressure 4kg / cm 2 , the temperature of the hot reel is 110°C, the speed of the reel is 2.0m / min, and the temperature of the plate is 55°C;

[0092] 3. Graphic plating

[0093] In this embodiment, the electroplating current density is 21ASF, and the electroplating time is 270min.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com