Chromium-free passivation liquid for treating tin-plated steel plate

A technology of chrome-free passivation and tin-plated steel, which is applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., and can solve problems such as polluting the environment, endangering human health, and high toxicity of hexavalent chromium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

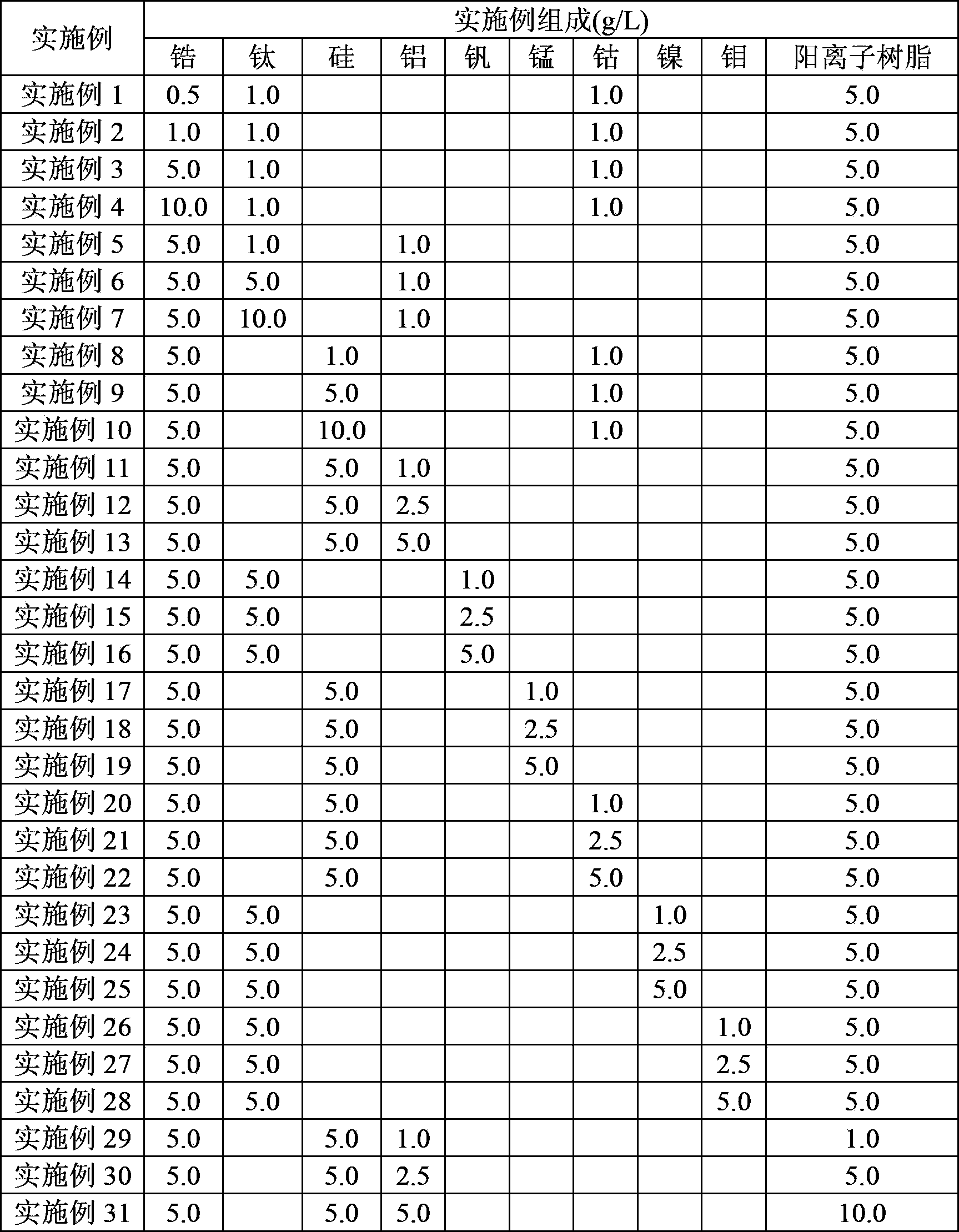

Examples

Embodiment 1

[0029] Ammonium fluozirconate 1.32g, potassium fluotitanate 5.4g, cobalt nitrate 4.94g, add water to dissolve in 1L, in which zirconium content is 0.5g / L, titanium and cobalt content are both 1.0g / L, then add commercially available 5.0 g of water-soluble acrylic cationic resin was stirred and mixed evenly, and finally 86 wt % of phosphoric acid was added to adjust the final pH to 3.0.

Embodiment 2

[0031] Ammonium fluozirconate 2.65g, potassium fluotitanate 5.4g, cobalt nitrate 4.94g, add water to dissolve in 1L, wherein zirconium content is 1.0g / L, titanium and cobalt content are both 1.0g / L. Subsequently, 5.0 g of a commercially available water-soluble acrylic cationic resin was added, fully stirred and mixed evenly, and finally 86 wt % of phosphoric acid was added to adjust the final pH to 3.0.

Embodiment 3

[0033] Ammonium fluozirconate 13.23g, potassium fluotitanate 5.4g, cobalt nitrate 4.94g, add water to dissolve in 1L, wherein zirconium content is 5.0g / L, titanium and cobalt content is 1.0g / L. Subsequently, 5.0 g of a commercially available water-soluble acrylic cationic resin was added, fully stirred and mixed evenly, and finally 86 wt % of phosphoric acid was added to adjust the final pH to 3.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com