Steel strip tinning method

A technology of strip steel and tin plating, which is applied in the field of surface treatment of metal materials, can solve the problems of uneven coating thickness, uneven and smooth surface of tin layer, unsuitable surface for coating and printing, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Original board

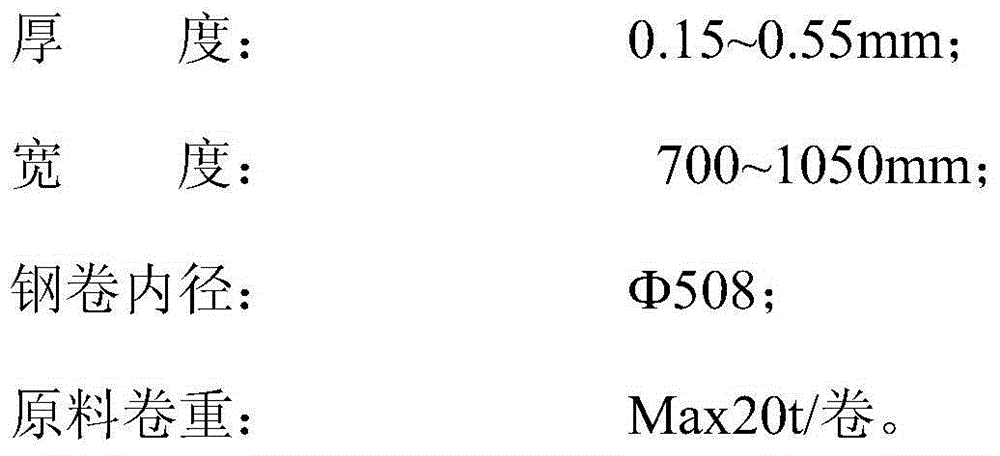

[0051] 1) Specifications

[0052]

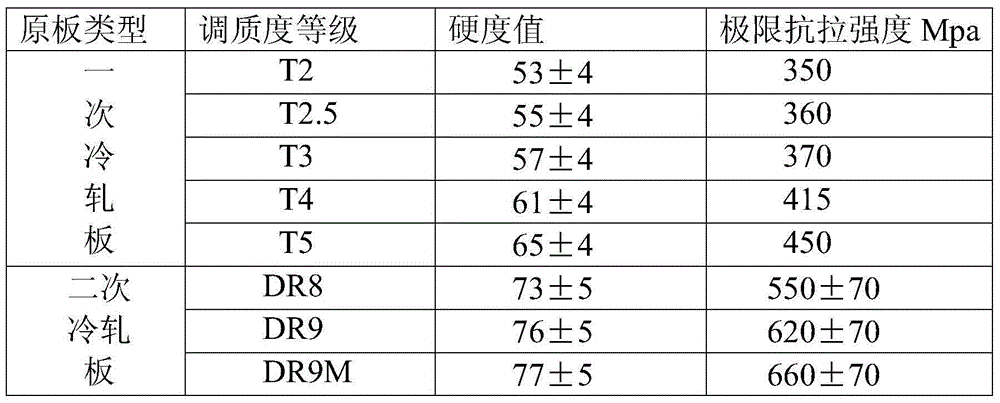

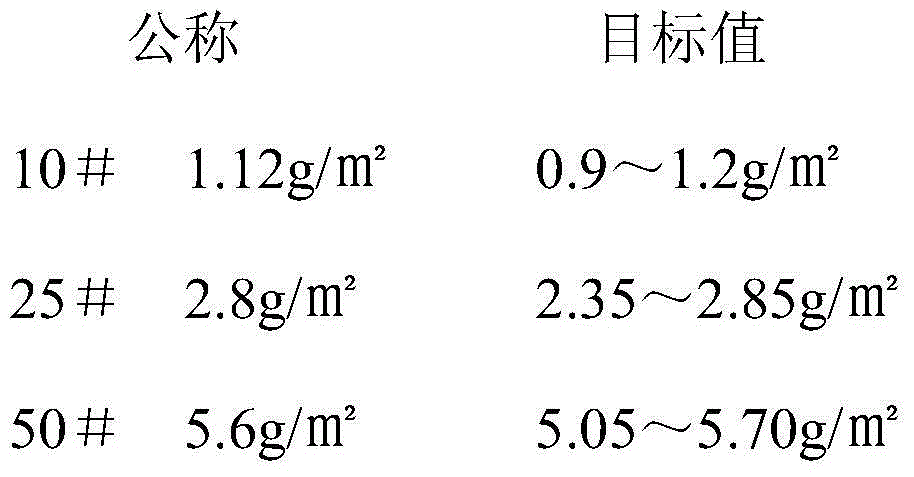

[0053] 2) Mechanical properties:

[0054] Tensile strength: 451N / mm 2 ;

[0055] Yield limit: 294N / mm 2 ;

[0056] 3) Hardness value:

[0057]

[0058] 4) Surface condition of the original board: The surface of the original board should be clean and rust-free, and the oil should be evenly coated. The amount of oil applied is 30-70mg / ㎡ (double-sided). Generally, stone-grained, pitted, and shiny surfaces are used.

[0059] 5) Dimensional tolerance: the maximum thickness tolerance of a steel plate shall not exceed ±8.5%, and the target value ≤±4%; the maximum difference of the same plate shall not exceed 4%, and the target value ≤2%; width tolerance +3, -0.

[0060] 6) Others: The coiling state of the original board should be neat and tight, and tower-shaped, heart-shaped, etc. are not allowed. The board shape is good. There are side waves or middle waves over 3mm, or although there are side waves or middle waves less than 3mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com