Alkyl sulfonic acid chemical tinning solution and chemical tinning solution based tinning process

A technology of alkyl sulfonic acid chemistry and tin plating solution, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of high cost, high price, complicated processing process, etc., and achieve good solderability Sexuality, bright coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The alkylsulfonic acid electroless tin plating process includes the following steps:

[0043] 1) Pretreatment: Degreasing, pickling, and micro-etching the copper or copper alloy workpiece to be plated, and then replacing a thin and uniform tin layer on the surface of the copper or copper alloy workpiece by conventional methods to complete the preplating treatment ;

[0044] 2) Put the pretreated copper or copper alloy workpiece into an alkylsulfonic acid chemical tin plating solution for tin plating; wherein, the temperature T of the chemical tin plating bath is 50°C, the pH value of the plating solution is 1.5, and the time t is 20 minutes ;

[0045] 3) Neutralize and prevent discoloration by conventional methods after tin plating.

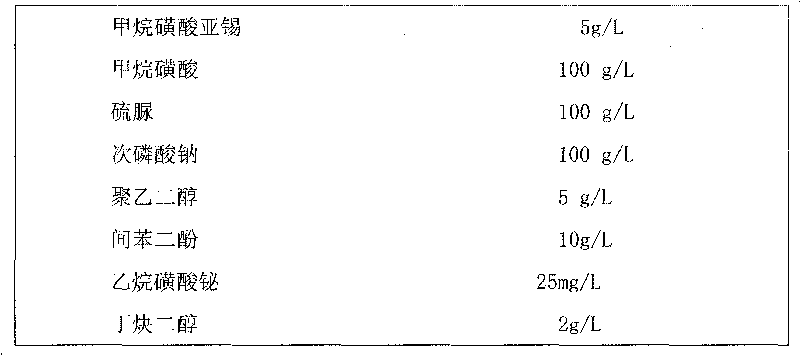

[0046] In step 2), the alkylsulfonic acid electroless tin plating solution is prepared according to the ingredients listed in Table 1.

[0047] The obtained tin layer was dried and tested for performance, and the test results are shown in...

Embodiment 2

[0053] The difference from Example 1 is: step 2) put the pretreated copper or copper alloy workpiece into an alkylsulfonic acid chemical tin plating solution for tin plating; wherein, the temperature T of the chemical tin plating bath is 55° C., and the plating solution The pH value is 2.0, and the time t is 30 minutes.

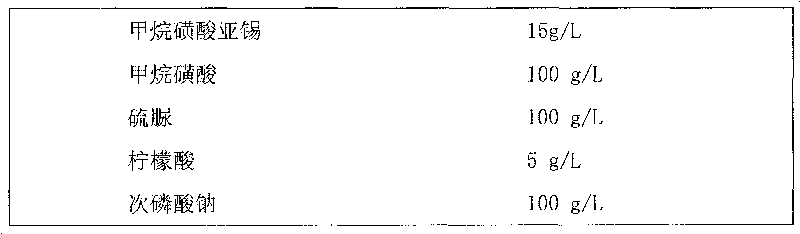

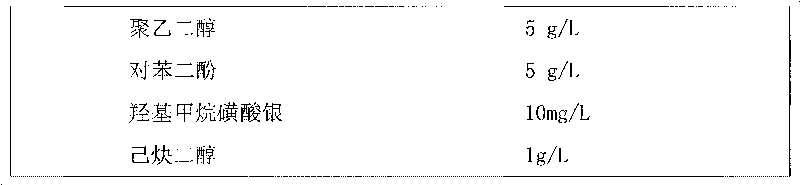

[0054] In step 2), the alkylsulfonic acid electroless tin plating solution is formulated according to the ingredients listed in Table 3. The test results are shown in Table 4.

[0055] Table three

[0056]

[0057]

[0058] Table four

[0059] Exterior

Embodiment 3

[0061] The difference from Example 1 is: step 2) putting the pretreated copper or copper alloy workpiece into an alkylsulfonic acid chemical tin plating solution for tin plating; wherein, the temperature T of the chemical tin plating bath is 65° C., and the plating solution The pH value is 1.5, and the time t is 15 minutes.

[0062] In step 2), the alkylsulfonic acid electroless tin plating solution is formulated according to the ingredients listed in Table 5. The tested results are shown in Table 6.

[0063] Table five

[0064]

[0065] Table six

[0066] Exterior

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com