Preparation method of solid wood furniture cleaning agent

A preparation method and cleaning agent technology, applied in the direction of detergent composition, chemical instrument and method, soap detergent composition, etc., can solve the problem of affecting the appearance performance and service life of solid wood furniture, unsatisfactory maintenance effect of solid wood furniture, surface paint Susceptible to corrosion and other problems, to achieve remarkable maintenance effects, excellent performance, and non-erosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

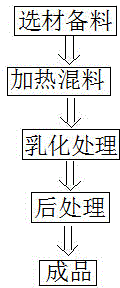

[0016] The specific preparation process of the embodiment solid wood furniture cleaning agent that the present invention mentions is as follows:

[0017] a) Material selection and preparation, the main components and percentage ratio of solid wood furniture cleaning agent are: solvent 4%, oxidized microcrystalline wax 2.5%, emulsifier 3%, surfactant 0.8%, brightening agent 2%, complexing The solvent is 1%, and the rest is water; wherein, the solvent is selected from acetone solution; the emulsifier is selected from polyoxyethylene stearate; the surfactant is selected from stearyl alcohol; the brightening agent silicone oil; the complexing agent is selected from triethanolamine;

[0018] b) Heating and mixing, the preparation process is as follows: First, add the oxidized microcrystalline wax to the mixing tank, and control the temperature of the mixing tank at 65°C-70°C to make it fully melt; then, add solvent, surfactant, and brightener in sequence and complexing agent, the t...

Embodiment 2

[0022] The specific preparation process of the embodiment solid wood furniture cleaning agent that the present invention mentions is as follows:

[0023] a) Material selection and preparation, the main components and percentage ratio of solid wood furniture cleaning agent are: solvent 5%, oxidized microcrystalline wax 3%, emulsifier 4%, surfactant 1%, brightening agent 2%, complexing The solvent is 1.2%, and the rest is water; wherein, the solvent is selected from ethyl acetate solution; the emulsifier is selected from polyoxyethylene oleate; the surfactant is selected from stearyl alcohol; the brightening agent silicone oil; the complexing agent is selected from triethanolamine;

[0024] b) Heating and mixing, the preparation process is as follows: First, add the oxidized microcrystalline wax to the mixing tank, and control the temperature of the mixing tank at 65°C-70°C to make it fully melt; then, add solvent, surfactant, and brightener in sequence and complexing agent, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com