Chip with high conductivity

A high-conductivity, chip technology, applied in circuits, electrical components, electrical solid devices, etc., to achieve excellent electrical conductivity, stable thermal conductivity, and a wide range of applicable temperatures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

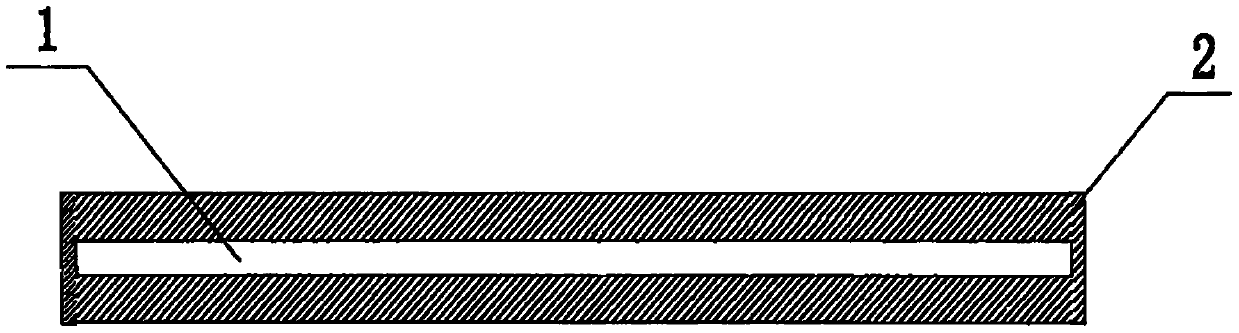

[0010] A chip with high conductivity includes a substrate 1, and a conductive layer 2 outside the substrate 1.

[0011] The conductive layer 2 is a nano-diamond layer. The nano-diamond layer is formed by uniformly spreading nano-diamond paste on the substrate 1 .

[0012] The thickness of the nanodiamond layer is 1-3 nanometers.

[0013] The substrate 1 has a thickness of 1.5-2.5 mm.

[0014] Nano-diamond paste is a new type of material, generally gray paste, with a thermal conductivity of 4.7w / m K and a dielectric constant of 14.5at1MHz. In addition to the general properties of diamonds, nano-diamond paste also has many properties of nano-materials, such as non-toxicity, small size effect, surface / interface effect, quantum size effect, macroscopic quantum tunneling effect, and has a very broad application prospect. However, the biggest problem facing the application and research of nanodiamonds at present is to solve the deagglomeration of hard aggregates and the stable di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com