Multi-layer film and medicine container using the same

a multi-layer film and medicine container technology, applied in the field of multi-layer film and medicine container using the same, can solve the problems of deterioration of properties such as strength and flexibility of the medicine container, decrease in the content of the medicine, interference with pre-mixing, etc., and achieve the effect of improving heat resistance and improving flexibility of the multi-layer film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(Example 1)

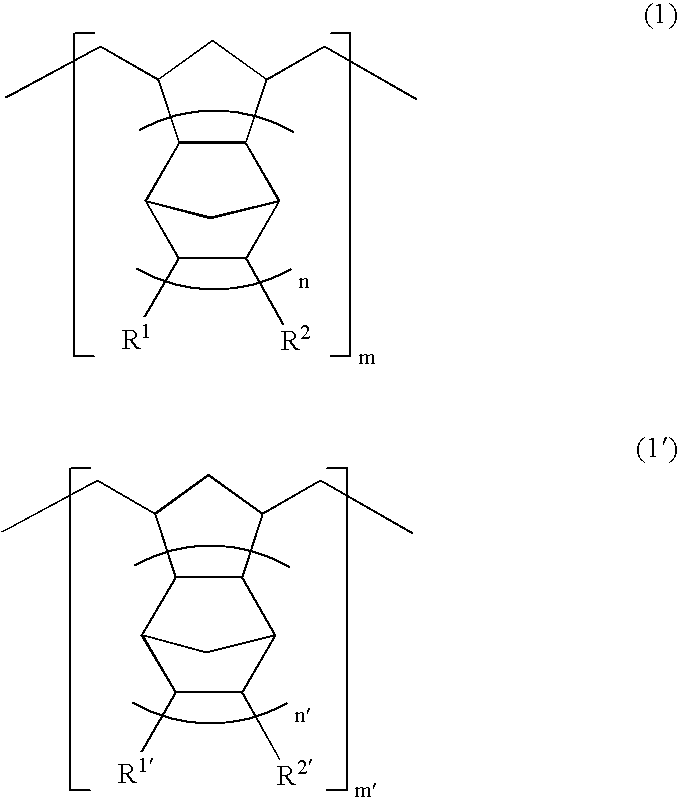

[0097] The resin A, the resin C, a mixed resin containing the resin E and the resin A in a weight ratio of 3:1 [mixing ratio of a cyclic olefin polymer (CO) :75% by weight] and the resin A were respectively used as the surface layer, the flexible layer, the barrier layer and the seal layer.

[0098] The surface layer, the flexible layer, the barrier layer and the seal layer were laid one upon another in this order, and then a multi-layer film having a total thickness of 230 μm (each of constituent layers formed from the side of the surface layer in the above order has a thickness of 20 μm, 170 μm, 30 μm or 10 μm) was formed by a water-cooling coextrusion inflation method.

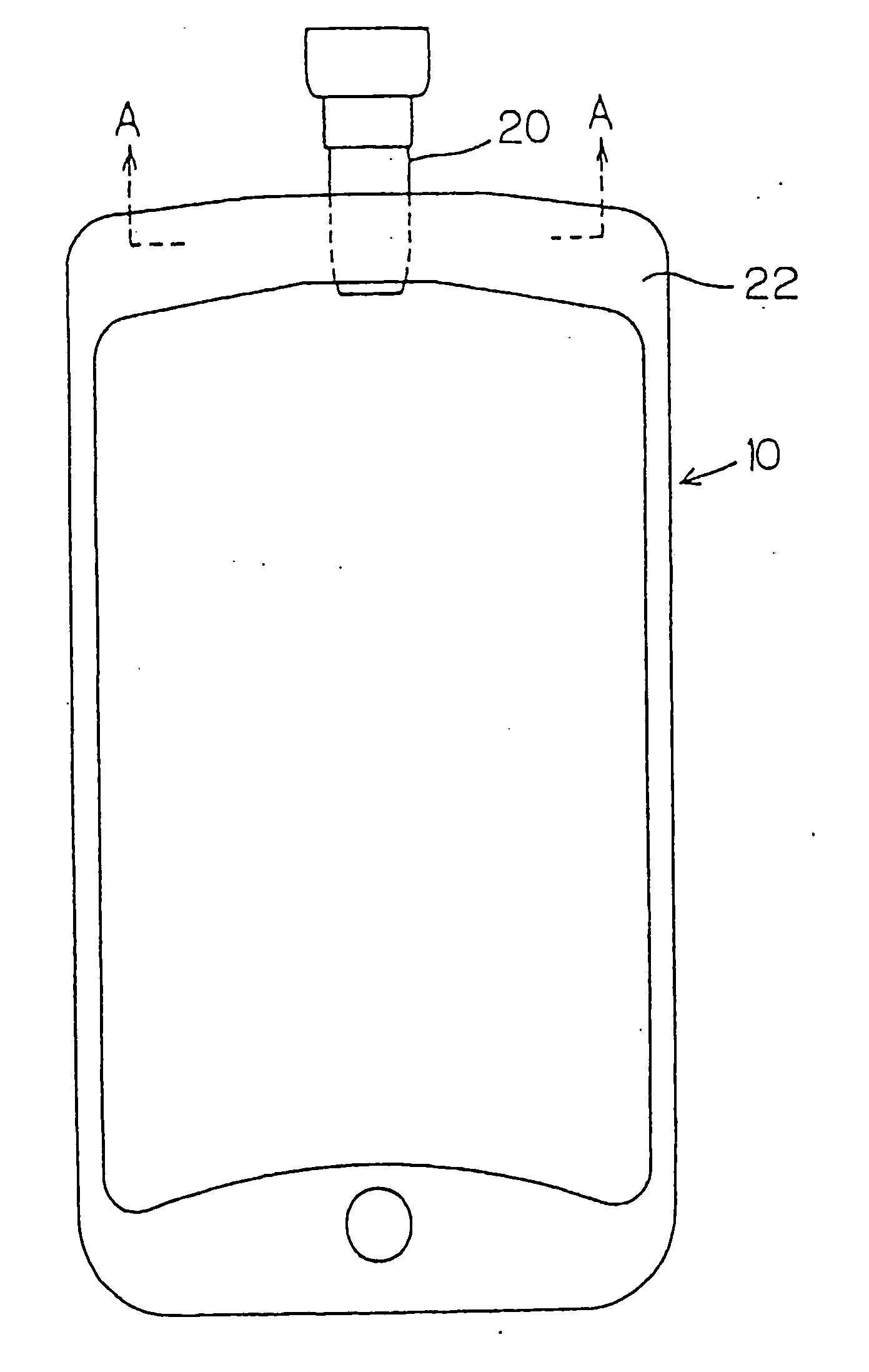

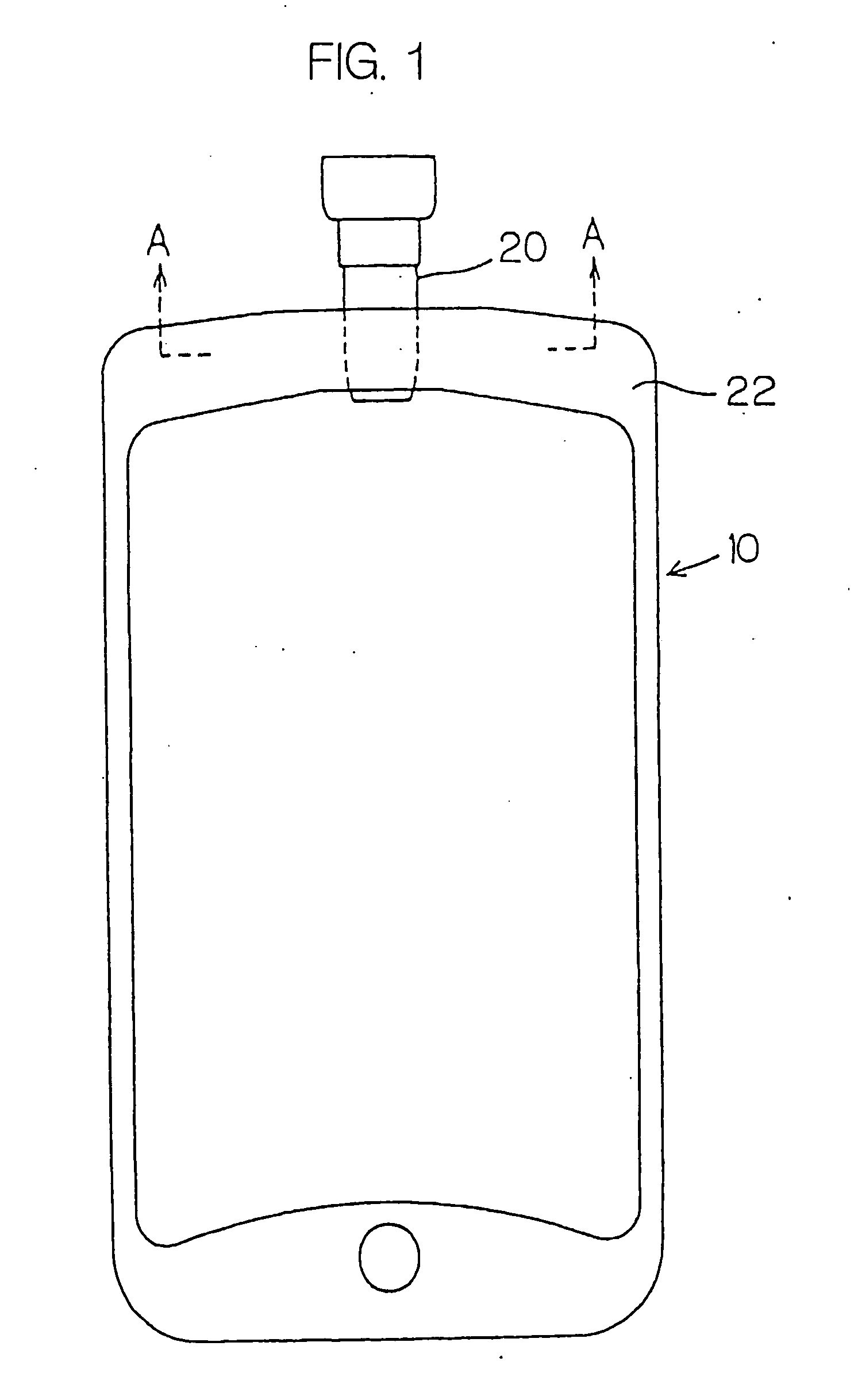

[0099] Using the resulting multi-layer film, a medicine bag (medicine container) 10 shown in FIG. 1 was produced. Polyethylene was used as the material of a port member 20. Sealing of the port member 20 was conducted at 140 to 150° C. for 3 seconds, while sealing of a peripheral portion 22 was conducted at...

example 2

(Example 2)

[0100] The resin A, a mixed resin containing the resin C and the resin D in a weight ratio of 95:5 [mixing ratio of a high-density polyethylene (HDPE): 5% by weight], a mixed resin containing the resin F and the resin C in a weight ratio of 3:1 [mixing ratio of CO: 75% by weight] and the resin B were respectively used as the surface layer, the flexible layer, the barrier layer and the seal layer.

[0101] The surface layer, the flexible layer, the barrier layer and the seal layer were laid one upon another in this order, and then a multi-layer film having a total thickness of 230 μm (each of constituent layers formed from the side of the surface layer in the above order has a thickness of 20 μm, 175 μm, 20 μm or 15 μm) was formed by a water-cooling coextrusion inflation method.

[0102] In the same manner as in Example 1, except that the above multi-layer film was used, a medicine bag 10 shown in FIG. 1 was produced.

example 3

(Example 3)

[0103] In the same manner as in Example 2, except that the barrier layer was made of a mixed resin containing the resin F and the resin C in a weight ratio of 3:2 [mixing ratio of CO: 60% by weight], a multi-layer film (total thickness: 230 μm) was formed and a medicine bag was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com