Utilization method of butadiene extraction device residue

An extraction device and butadiene technology, which is applied in the field of utilization of butadiene extraction device residues, can solve the problems that can only be counted by months or even weeks, the processing capacity of the hydrogenation device is large, and the catalyst loses its activity. Achieve the effect of improving utilization rate, good performance and inhibiting the generation of polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

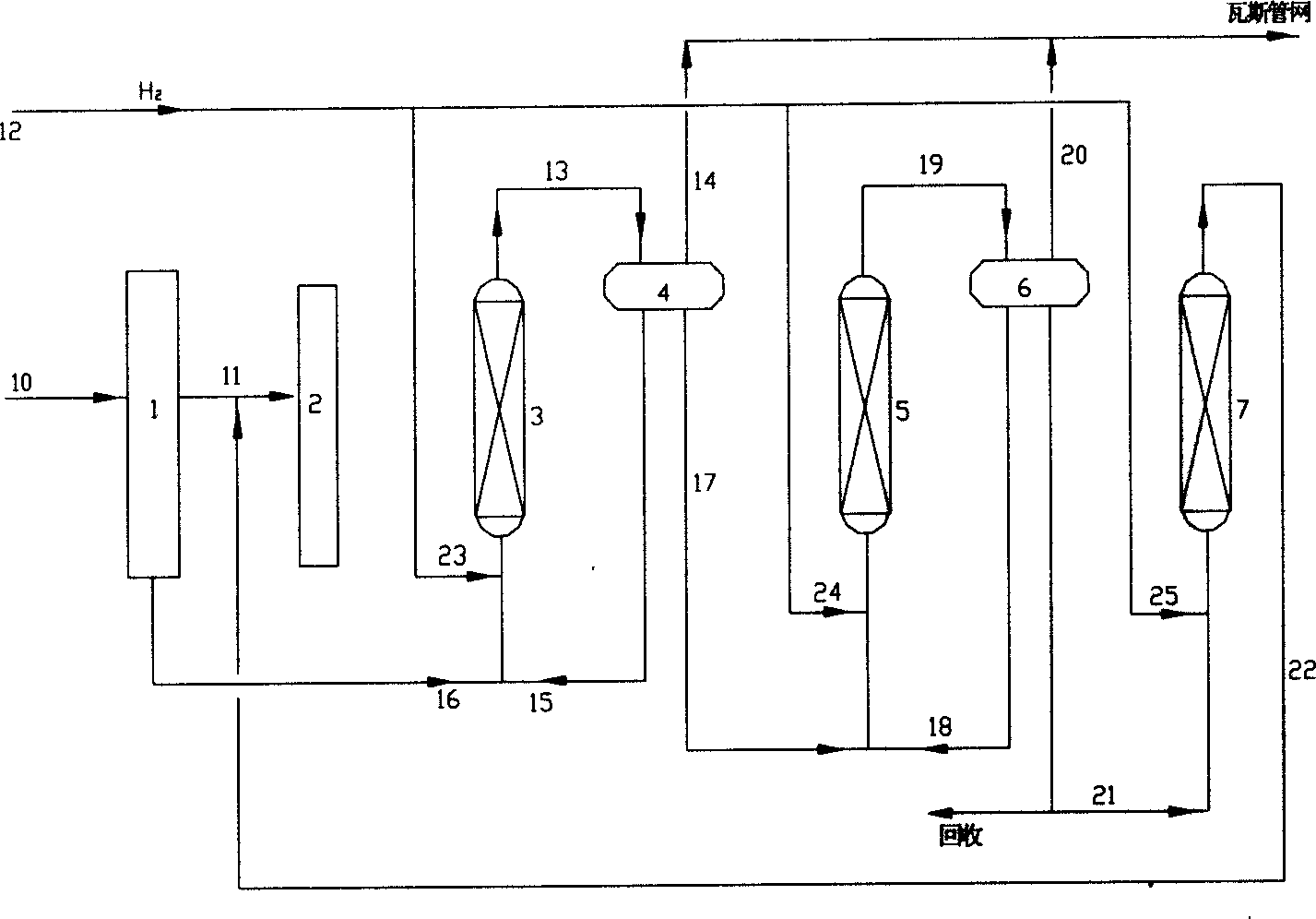

Image

Examples

Embodiment 1

[0039] The feed in this embodiment is a material rich in alkynes. The alkyne hydrogenation reactor uses a palladium-copper-silver polymetallic catalyst, the content of which is 0.2wt% of palladium, 9.5wt% of copper, and 0.2wt% of silver, and the catalyst carrier is alumina , The hydrogenation reactor is a two-stage adiabatic fixed-bed reactor, the inlet temperature of the first stage bed is 18℃, the inlet temperature of the second stage bed is 25℃, the pressure is 2.5MPa, and the liquid volumetric space velocity of high alkyne materials is 2.0h -1 , The hydrogen enters the first stage bed and the second stage bed separately in two ways. The molar ratio of hydrogen to alkyne in each stage bed is 1:1~2:1, and the circulation ratio is 18:1. Table 1 lists the materials before and after the reaction. composition.

[0040]

[0041] In the hydrogenation process of alkynes, in addition to the hydrogenation of alkynes, 1,3-butadiene can be hydrogenated to 1-butene, butyne is hydr...

Embodiment 2

[0046] The feed in this embodiment is a material rich in alkynes. The alkyne hydrogenation reactor uses a palladium-copper bimetallic catalyst with a content of 0.2wt% palladium and 9.5wt% copper. The catalyst carrier is alumina, and the hydrogenation reactor is Single-stage adiabatic fixed-bed reactor, the bed inlet temperature is 22℃, the pressure is 2.0MPa, and the liquid volumetric space velocity of high alkyne materials is 2.0h -1 The molar ratio of hydrogen to alkyne is 1:1 to 2:1, and the recycle ratio is 13:1. Table 2 lists the composition of the materials before and after the reaction.

[0047]

[0048] It can be seen from Table 3 that after 1000 hours of operation, the catalyst still has good activity and stability. The residual alkyne content is below 0.8w%, the alkyne conversion rate is above 98w%, and the butadiene and 1-butene remain relatively stable. High yield.

[0049] The resulting product is sent to a butadiene hydrogenation reactor, using a catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com