Catalyst in a highly active hydrogenation reaction of aromatic nitro compounds and preparation method thereof

An aromatic nitro, hydrogenation reaction technology, applied in the preparation of amino compounds, the preparation of organic compounds, the preparation of amino hydroxy compounds, etc., can solve problems such as very little graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

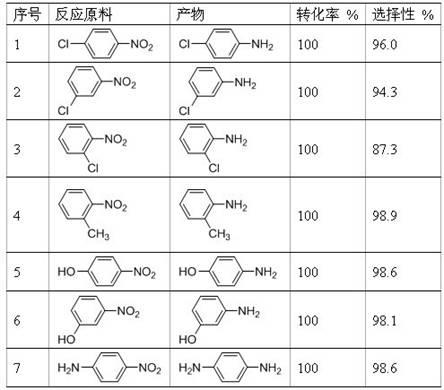

Image

Examples

preparation example Construction

[0019] 1. The preparation process of graphene oxide (GO)

[0020] (1) Add 230 mL of 98% concentrated sulfuric acid into a 500 mL beaker, and control the temperature at 0°C;

[0021] (2) Add 10 g of graphite powder and 5 g of sodium nitrate, and stir for 1 h;

[0022] (3) Add 30 g of potassium permanganate powder under vigorous stirring, and control the temperature not to exceed 20°C during the addition process;

[0023] (4) Remove the low-temperature ice bath, and stir in a water bath at 35°C for 30 min;

[0024] (5) Add 460 mL of deionized water under stirring, raise the temperature of the reaction solution to about 98°C, and continue stirring for 1 h.;

[0025] (6) Dilute the reaction solution with 1.4 L deionized warm water, then add a certain amount of 3% hydrogen peroxide solution;

[0026] (7) Filtrate while hot, and wash the filter cake fully until there is no sulfate ion in the filtrate.

[0027] 2. Preparation process of graphene-supported Pt catalyst (Pt / RGO)

...

Embodiment 1

[0040] Take 0.02 g of catalyst and transfer it into the reaction kettle with 30 mL of ethanol. Put the reaction kettle into a water bath at 0°C, and stir for precooling for 1 h. After that, 1 mL of nitrobenzene was added quickly, and the reaction kettle was tightly closed. Check the airtightness of the reactor and fill it with hydrogen to 1 MPa. Then put the reaction kettle into a water bath at a set temperature, start stirring to 1000 rpm, and react for 180 min. After the set reaction time, stop the reaction. Take out the reaction solution in a 50 mL volumetric flask, add quantitative internal standard toluene, and make the volume to the mark. Then centrifuged, and the supernatant was taken for gas chromatography analysis. The results showed that the conversion rate of nitrobenzene was 100%, and the selectivity of aniline was 94.3%.

[0041]

Embodiment 2

[0043] Referring to the preparation method and steps of Example 1, the difference is that the reaction temperature was increased to 20°C, and the reaction time was shortened to 20 min. The results showed that the conversion rate of nitrobenzene was 100%, and the selectivity of aniline was 99.1%.

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com