Composition function agent for improving mechanical property of solid propellant, and solid propellant comprising composition function agent

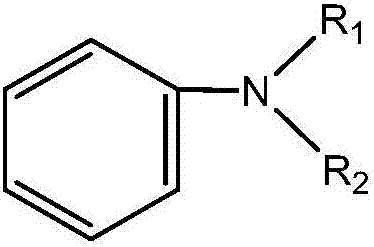

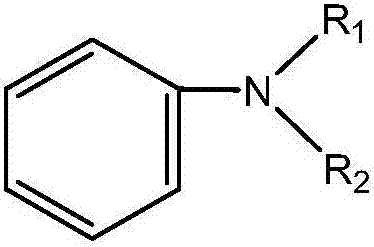

A technology of solid propellant and functional additives, which can be used in aromatic nitration compositions, offensive equipment, non-explosive/non-thermal agent components, etc. To solve problems such as compatibility, no interaction between aniline and nitrate, etc., to achieve the effect of improving chemical compatibility, increasing strength and modulus, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

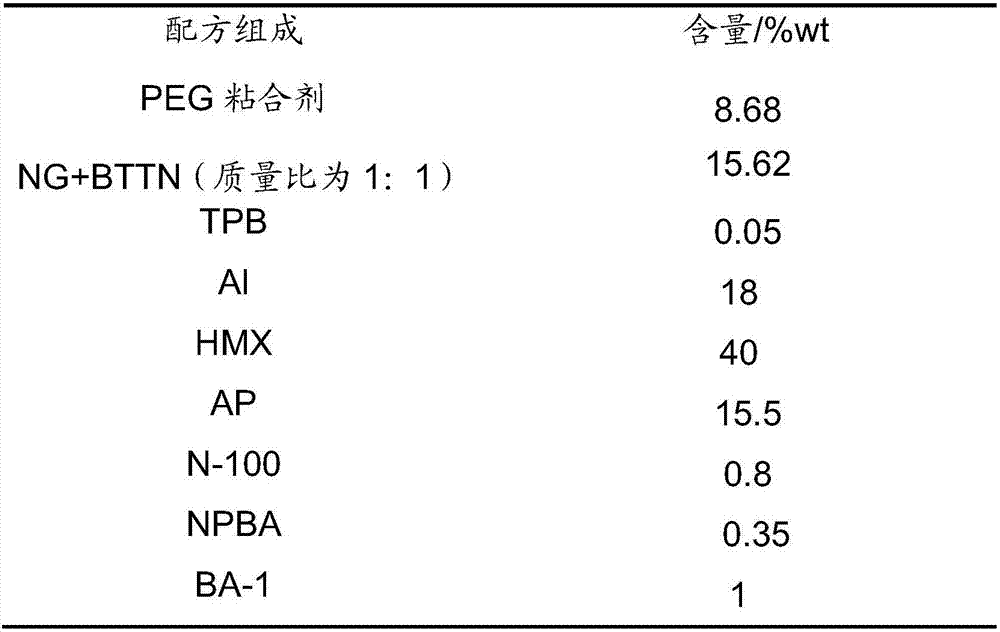

[0043] Propellant composition (mass percentage content)

[0044]

[0045] Wherein the above-mentioned combined functional auxiliary agent BA-1 comprises:

[0046]

[0047] Table 1 shows the chemical stability test results of the high-energy propellant billet prepared by adding BA-1. It can be seen that, compared with the blank, the addition of aniline alone will deteriorate the chemical stability of the propellant, while the chemical stability of the propellant added with BA-1 is good, the anti-crack time at 90°C is greater than 20 days, and the spontaneous combustion time is greater than 90 days The thermal weight loss rate is less than 1.5%.

[0048] Table 1 Propellant chemical stability test results

[0049]

[0050]

Embodiment 2

[0052]The mechanical property test results of the propellant prepared in Example 1 are shown in Table 2. It can be seen from Table 2 that, compared with the blank, the mechanical properties of the propellant are improved when aniline is used alone, and the effect of BA-1 on the mechanical properties of the propellant is more obvious.

[0053] Table 2 Comparison of the effects of additives

[0054]

Embodiment 3

[0056] The effect of the addition amount of aniline combined functional additive BA-1 on the high-energy propellant, the results are shown in Table 3. It can be seen from Table 3 that when BA-1 is not added, the modulus of the propellant is low and the elongation is high, which cannot meet the needs; while BA-1 can significantly increase the strength and modulus of the high-energy propellant, and slightly reduce the elongation Rate.

[0057] Table 3 Effect of the dosage of aniline combined functional additive BA-1

[0058]

[0059] It can be seen from Table 3 that when the high-energy propellant contains 1% combined functional additive (BA), the overall performance of the propellant is better and can meet the requirements of use, and with the increase of BA content, the strength and modulus of the propellant increase , the elongation decreased slightly, but it met the requirements for use. Therefore, the total content of BA in the following examples is 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com