Process and production system for synthesizing dimethyl oxalate or diethyl oxalate and coproducing oxalic acid

A technology for synthesizing dimethyl oxalate and diethyl oxalate, which is applied in the preparation of carboxylate/lactone, the reaction preparation of carbon monoxide or formate, and organic chemistry, etc., can solve equipment corrosion, high energy consumption, and increased separation cost and other problems, to achieve the effect of large driving force, thorough absorption and reduction of separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

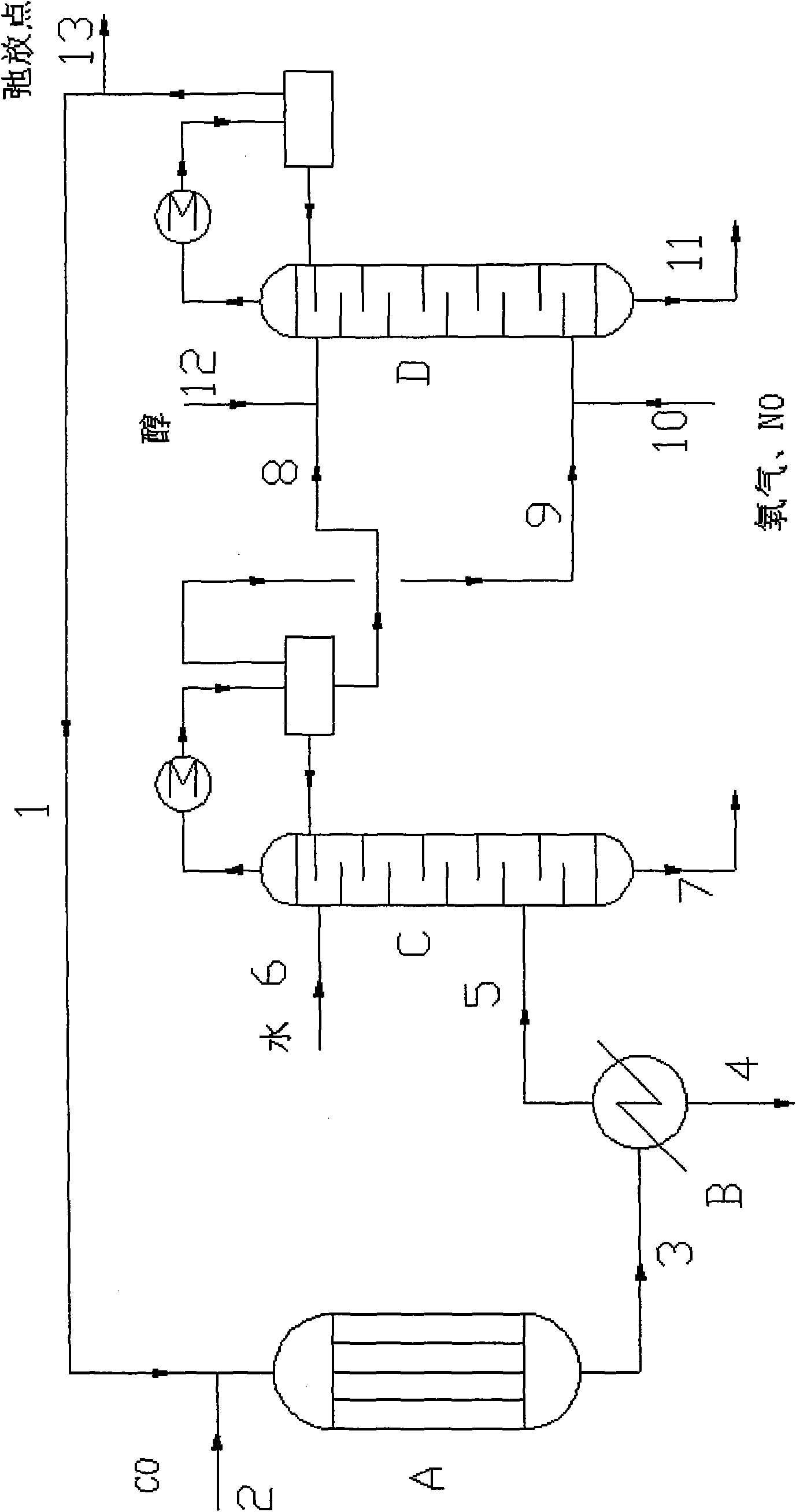

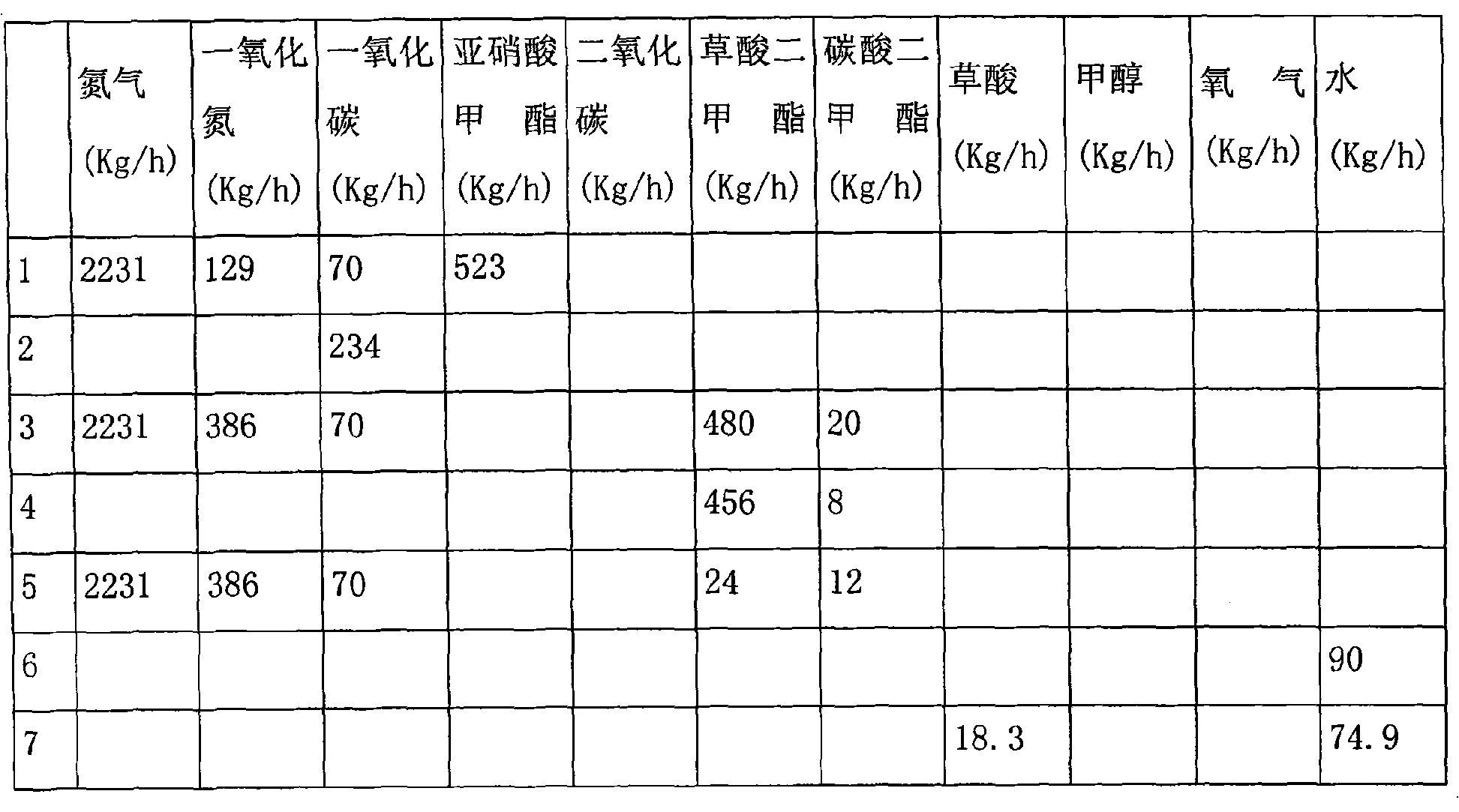

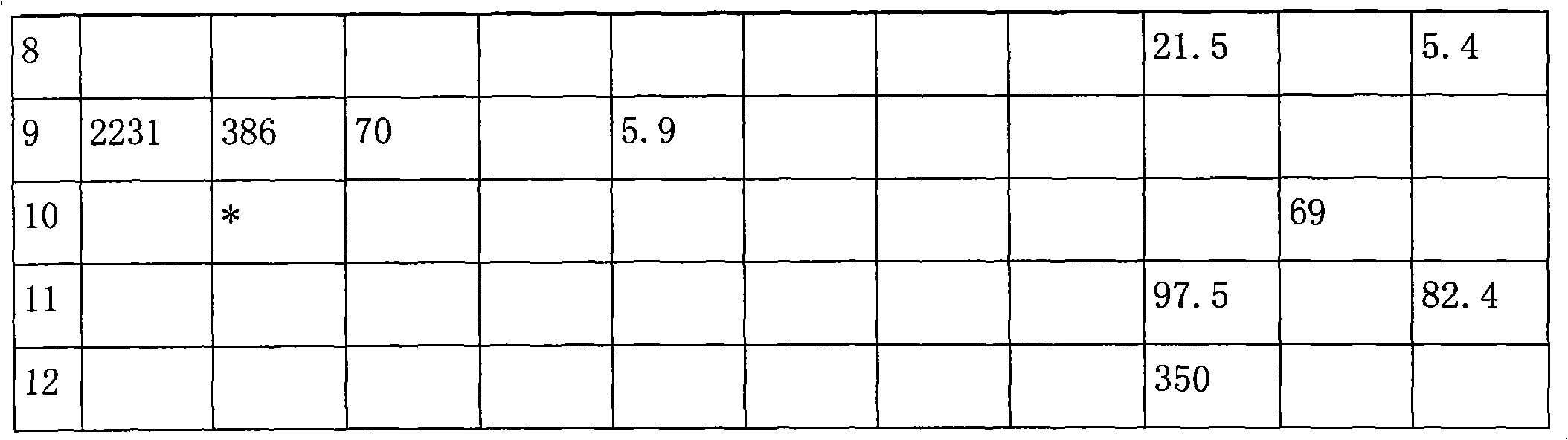

[0060] This embodiment is a process for the co-production of oxalic acid from dimethyl oxalate, and the pressure of all equipment is 0.1 MPa. The reaction temperature of equipment A gas-phase coupled carbonylation reactor is 140°C, and the catalyst is Pd / a-Al 2 o 3 , the process temperature of the equipment B condenser is 20°C, the equipment C oxalate ester hydrolysis reactor is designed as a reactive distillation column in this example, the temperature of the reaction zone is 85°C, the temperature of the condenser at the top of the oxalate ester hydrolysis reactor -5°C, the esterification reactor of equipment D is also designed as a reactive distillation column, and the temperature in the reaction zone is 40°C. The following table is the present embodiment according to the instructions attached figure 1 The composition of each pipeline material, attached figure 1 Pipeline No. 13 is the relaxation point. According to the technical requirements of the circulation system, the...

Embodiment 2

[0065] This example is a flow process for the co-production of oxalic acid from dimethyl oxalate, and the pressure of all equipment is 0.1 MPa. The reaction temperature of equipment A gas-phase coupled carbonylation reactor is 140°C, and the catalyst is Pd / a-Al 2 o 3 , the process temperature of the equipment B condenser is 40°C, the equipment C oxalate ester hydrolysis reactor is designed as a reactive distillation column in this embodiment, the temperature of the reaction zone is 85°C, the condenser at the top of the oxalate ester hydrolysis reactor The temperature is -5°C, and the esterification reactor of equipment D is also designed as a reactive distillation column, and the temperature in the reaction zone is 40°C. The following table is the example attached according to the manual figure 1 The composition of each pipeline material. attached figure 1 Pipeline No. 13 is the relaxation point. According to the technical requirements of the circulation system, the circul...

Embodiment 3

[0070]Except that the reaction zone temperatures of the equipment C oxalate ester hydrolysis reactor were respectively 25° C. and 98° C., the rest were the same as in Example 1. As a result, the output of dimethyl oxalate and oxalic acid is close to that of Example 1, indicating that the temperature of the hydrolysis reactor has little influence on the production capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com