Palladium catalyst for synthesizing oxalate using liquid phase coupling method and use thereof

A catalyst and oxalate technology, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, carbon monoxide or formate reaction preparation, etc. It can solve the problem of difficult product separation and catalyst synthesis of catalysts The problems of low yield and short catalyst life are achieved, and the effects of high selectivity, long catalyst life and high reaction yield are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

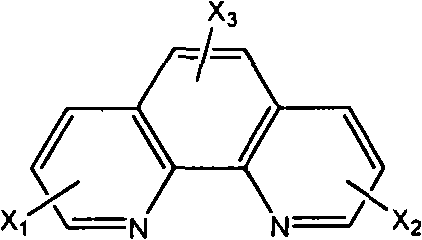

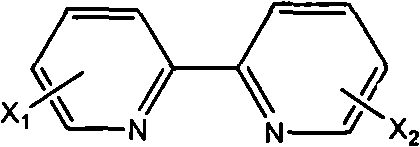

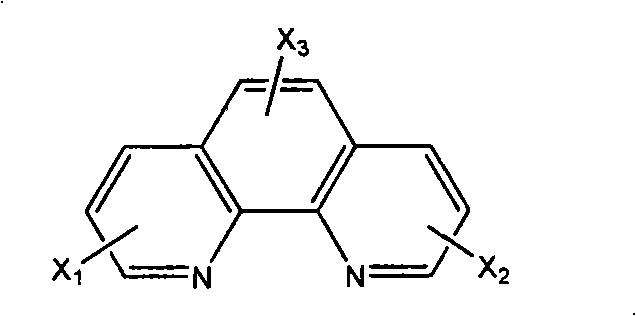

[0024] Pd(phen)Cl 2 (Phen is 1,10-phenanthroline) preparation

[0025] 1gPdCl 2 Mix with 1.5mL of 36% concentrated hydrochloric acid and 40mL of water, heat until dissolved, add 0.84g of KCl crystals in boiling state, continue to stir the reaction solution for 2h, cool, concentrate, and precipitate crystals to obtain K 2 PdCl 4 About 1.0g. Contains 5.6mmolK in 20mL 2 PdCl 4 To the aqueous solution, 20 ml of ethanol solution containing 5.6 mmol of phen was added to adjust the pH value to 4.47, and the reaction was stirred at 40° C. for 1 h to obtain a yellow precipitate. The precipitate was washed with deionized water until pH = 7, and dried in vacuo to obtain 1.2 g of the product. Take prepared Pd(phen)Cl 2 0.117g, PPh 3 Add 0.264g, 5.4g ethyl nitrite, and 35mL ethanol into the autoclave, first pass 1.0MPa of CO to replace the air for 3 times, then pass CO to 3.0MPa, control the temperature at 60°C, and react for 6h. After the reaction is completed, the reaction Liqui...

example 2

[0027] Take prepared Pd(phen)Cl 2 0.117g, PPh 3 Add 0.264g, 6.4g of propyl nitrite, and 35mL of n-propanol into the autoclave, first pass 1.0MPa of CO to replace the air for 3 times, then pass CO to 4.5MPa, control the temperature at 60°C, and react for 6h. After the reaction, The reaction solution was filtered, and the catalyst was dried to recover. The filtrate was analyzed by GC, and the yield of dipropyl oxalate was 65.3%, and the selectivity of dipropyl oxalate was 95.2%.

example 3

[0029] Take prepared Pd(phen)Cl 2 0.117g, PPh 3 Add 0.264g, 7.4g of butyl nitrite, and 35mL of n-butanol into the autoclave, first pass 1.0MPa of CO to replace the air for 3 times, then pass CO to 3.0MPa, control the temperature at 60°C, and react for 6h. After the reaction, The reaction solution was filtered, and the catalyst was dried to recover. The filtrate was analyzed by GC, and the yield of dibutyl oxalate was 47.2%, and the selectivity of dibutyl oxalate was 93.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com