Method of determining sampling time in accelerated storage test of NEPE (nitrate ester plasticized polyether) propellant

A technology for accelerated storage test and sampling time, which is applied in the field of sampling time for tensile strength change samples of NEPE propellant accelerated storage test, which can solve the problem of lack of economy, safety and effectiveness, uneven sampling, aging samples cannot accurately describe the change of aging performance law and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] (1) Constant temperature accelerated aging test

[0061] ①The charge sample is sealed, and the accompanying sample is sealed

[0062] The NEPE propellant billet is made into 120mm×25mm×10mm rectangular test pieces, each set of 6 pieces is packaged in an aluminum-plastic sample bag, and one set is taken as an accompanying sample.

[0063] ②Constant temperature accelerated aging test at set temperature

[0064] Adjust the safe water bath oven to keep the temperature constant at 70°C±1°C; place the packaged accompanying sample in the oven in advance, and after five days, place the packaged charge sample in the oven, and record the Time; during the test, the oven temperature is automatically recorded by the monitoring system;

[0065] ③ Accompanying sample sampling test

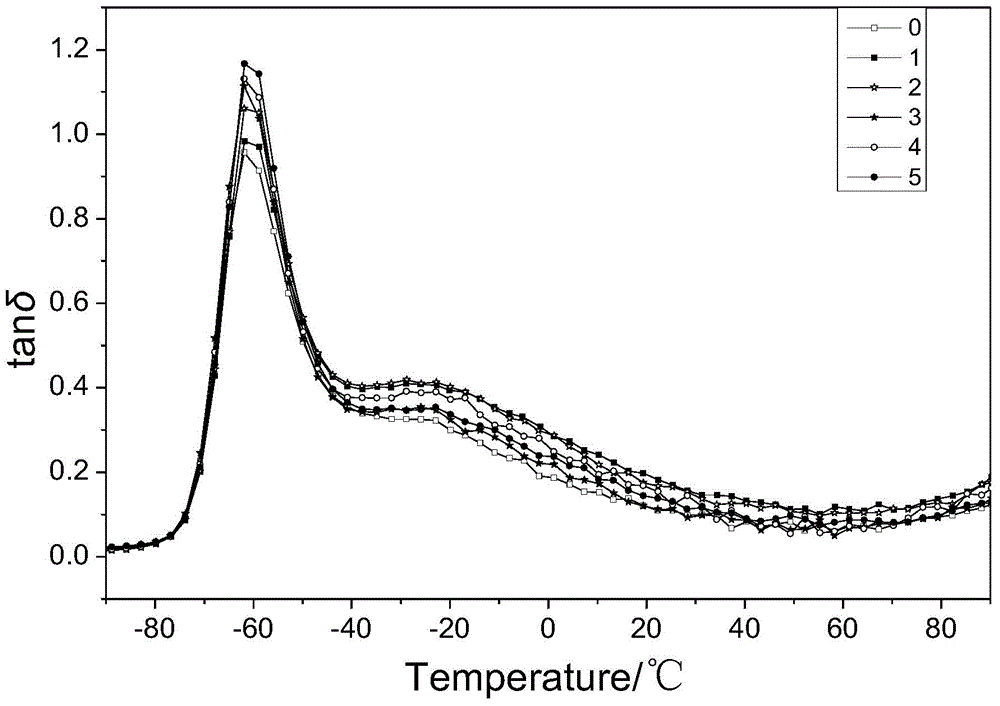

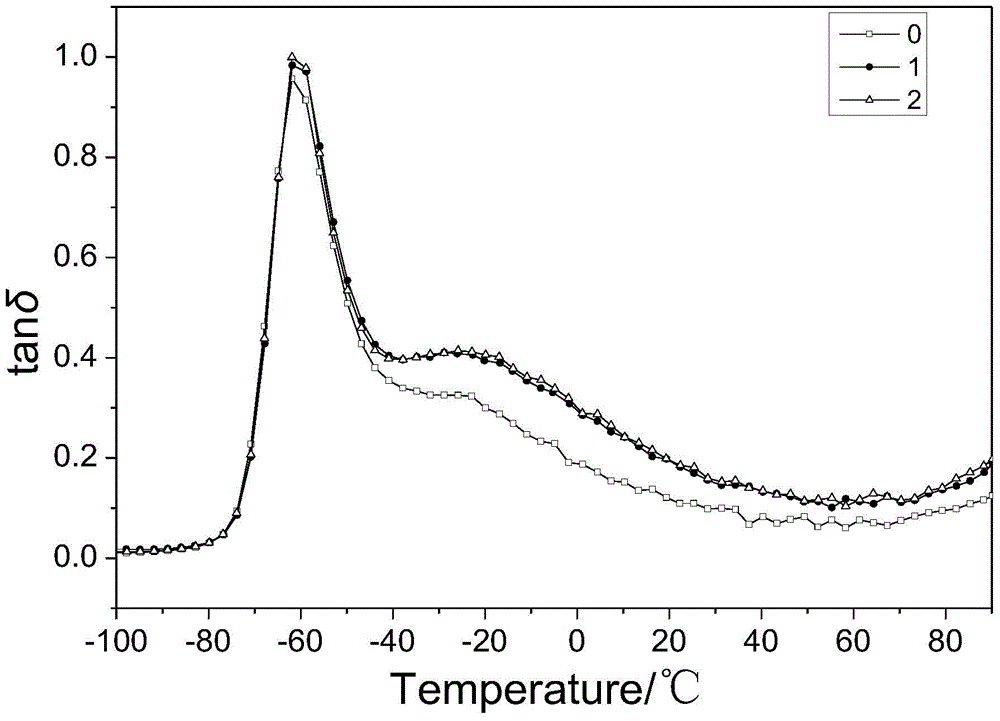

[0066] During the aging test, take out the accompanying sample every other day, after cooling to room temperature, cut a DMA test piece of 35mm×1.5mm×10mm on the 120mm×10mm surface of one of the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com