Method for testing combustion speed of NEPE (nitrate ester plasticized polyether) solid propellant

A solid propellant, burning rate technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of long curing process, solid propellant slurry to judge the burning rate of solid propellant, etc., to save samples Test time, overcoming the long time-consuming curing molding, the effect of convenient and quick detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

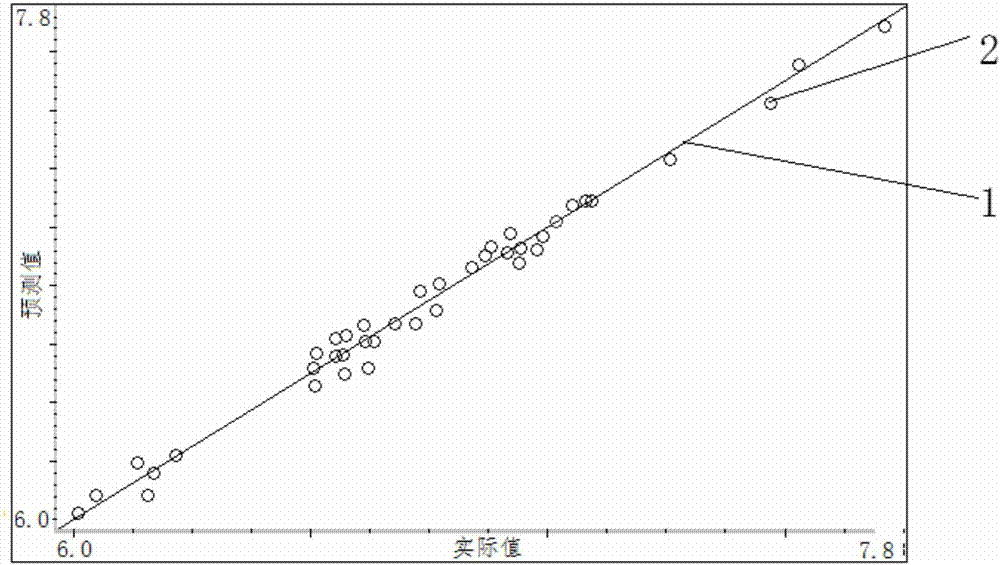

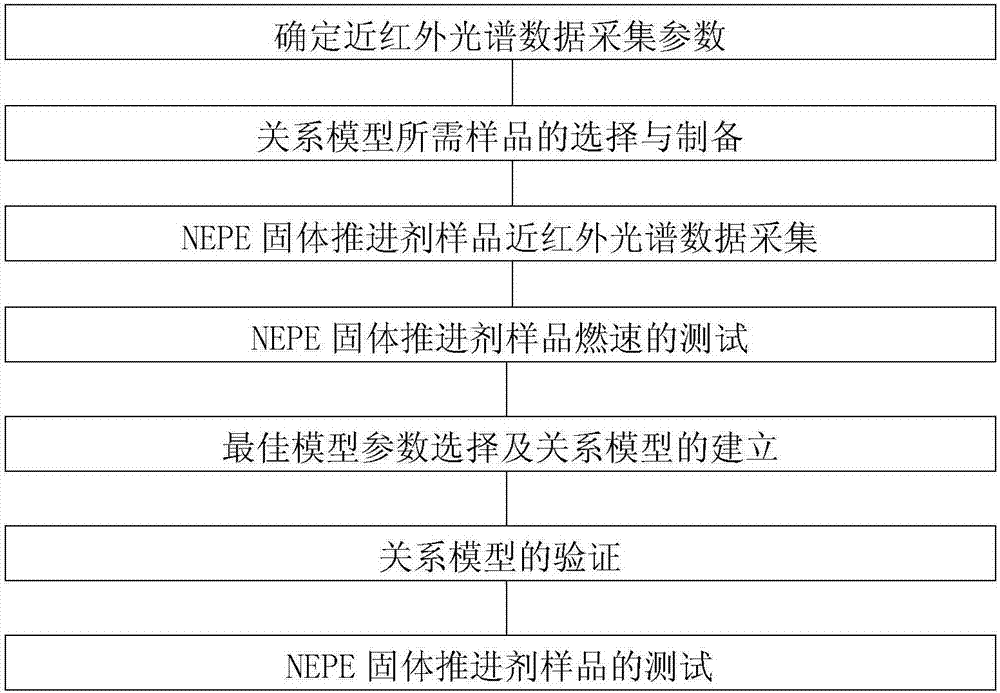

[0049]The invention is a method for testing the burning rate of NEPE solid propellant

[0050] Step 1, determine the near-infrared spectroscopy data acquisition parameters.

[0051] The near-infrared spectroscopy data acquisition parameters are determined by testing NEPE solid propellant slurry. The specific process is:

[0052] Take 5-10 parts of NEPE solid propellant slurry; carry out near-infrared spectrum test on said 5-10 parts of NEPE solid propellant slurry one by one, and obtain a set of near-infrared spectrum test curves. In the test, each NEPE solid propellant slurry was scanned in the full band in turn; the number of scans for each NEPE solid propellant slurry was selected as 50 times, 100 times, 120 times, 160 times, and 200 times. The resolution of one scan is 2cm -1 、4cm -1 、8cm -1 ; The number of scans is orthogonally matched with the resolutions.

[0053] A group of near-infrared spectrum test curves obtained is compared, and the parameters of the near-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com