Preparation method for methylnitrate

A technology of methyl nitrate and nitric acid, which is applied in the field of preparation of methyl nitrate, can solve problems such as hindering the application of methyl nitrate, high environmental and process requirements, etc., and achieve the effects of reducing retention time, improving safety, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

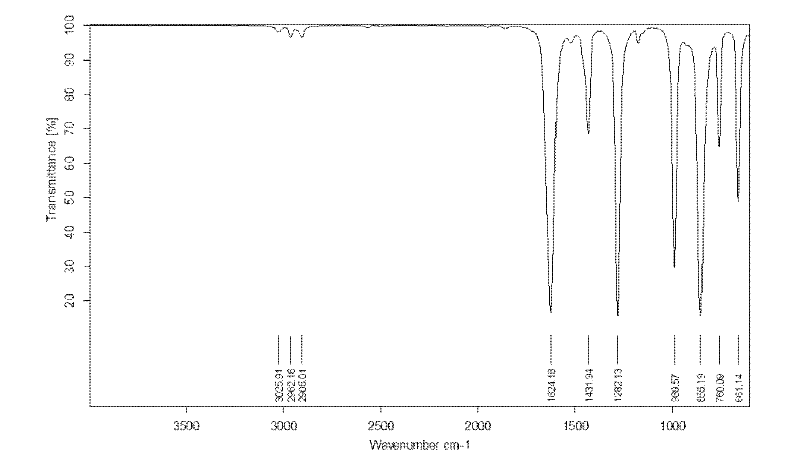

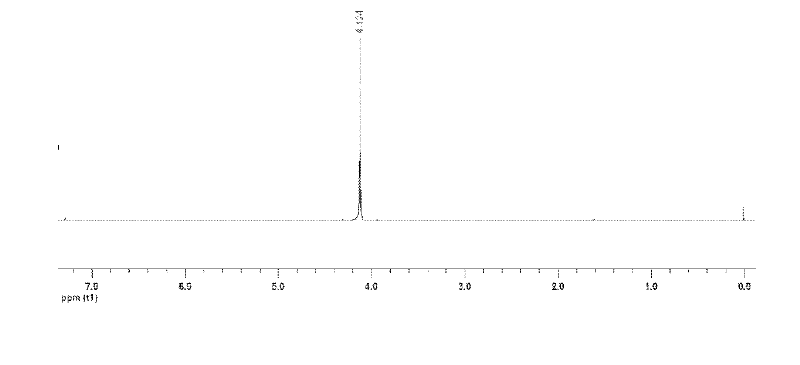

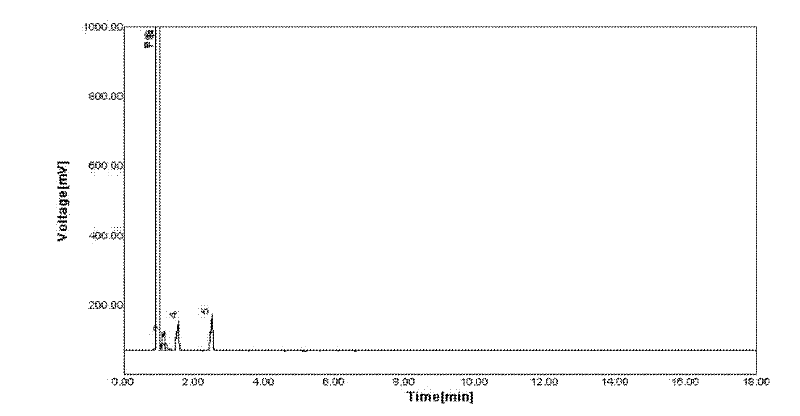

Image

Examples

Embodiment 1

[0026] In a 500ml three-necked flask heated by an oil bath, add 20g of urea and 5g of ammonium nitrate, add 100ml of distilled water to make them completely dissolve, and then add 30ml of 68% nitric acid in the reaction flask. When the temperature of the reaction bottle was raised to 55° C., 32 g of methanol was added dropwise, and 70 ml of 68% nitric acid was added dropwise. After reflux to 89°C, after 30 minutes, the distillation device was opened, and the crude product and water were brought out by the nitric acid vapor, which were separated rapidly. The lower layer was the product, and the upper layer was water and mixed acid. Collect until there is no effluent. Wash the collected product with water to neutrality, wash twice with 300ml of 0.05% sodium carbonate, wash twice with 500ml of water each time, obtain the crude methanol nitrate after separation, dry with dry magnesium sulfate for 36h, filter 76 g of methanol nitrate was obtained. The yield was 98.7%.

[0027] T...

Embodiment 2

[0029] In a 500ml three-necked flask heated by an oil bath, add 15g of urea and 5g of dicyandiamide, add 80ml of distilled water to dissolve it completely, then add 50ml of 68% nitric acid into the reaction flask, and mix well. When the temperature of the reaction flask was raised to 55° C., 48 g of methanol was added dropwise, and simultaneously, 50 ml of 68% nitric acid was added dropwise. Reflux to 85°C for 45 minutes, turn on the distillation device, and control the crude product and water brought out by the nitric acid vapor at 95°C, and separate quickly. The lower layer is the product, and the upper layer is water and mixed acid. Collect until there is no effluent.

[0030] Wash the collected product with water until it is neutral, then wash it twice with 1000ml of 0.05% sodium carbonate, and wash it three times with 500ml of water each time. After separation, the crude methanol nitrate is obtained, dried with dry magnesium sulfate for 36h, and filtered 111 g of methano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com