Patents

Literature

79 results about "Propyl nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopropyl nitrate (IPN, 2-propyl nitrate) is a colorless liquid monopropellant. It is used as a diesel cetane improver. IPN is a low-sensitivity explosive, with a detonation velocity of approximately 5400 m/s. Isopropyl nitrate is extremely flammable and burns with a practically invisible flame.

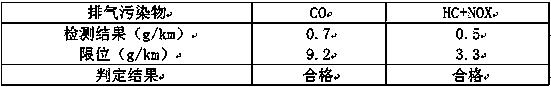

Adjustable fuel power booster component composition

InactiveUS20070204506A1Reduce gas emissionsBiofuelsLiquid carbonaceous fuelsMethyl carbonateInternal combustion engine

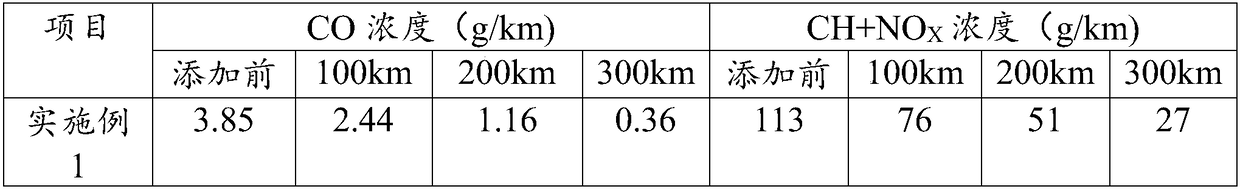

An adjustable fuel power booster component composition having three components: (A) an ignition accelerator which is preferably normal propyl nitrate and / or diterbutyl peroxide; (B) propylene glycol monoalkyl ether and / or butylene glycol monoalkyl ether; and (C) methyl carbonate and / or ethyl carbonate and / or propyl carbonate and / or butyl carbonate, which may be used mixed in any proportion with methylal (dimethoxymethane) or ethylal (diethoxymethane). The adjustable fuel power booster component composition of the present invention can be used by itself or in mixture with gasoline, diesel or burning oils in combustion engines without the need for modification thereof. The adjustable fuel power booster component composition enables low energy content alcohol based fuels to substitute conventional fuels, such as gasoline or diesel, in conventional non-modified internal combustion engines, thereby generating lower amounts of toxic gas emission all the while proving more power.

Owner:BRENES MARIO ARAYA

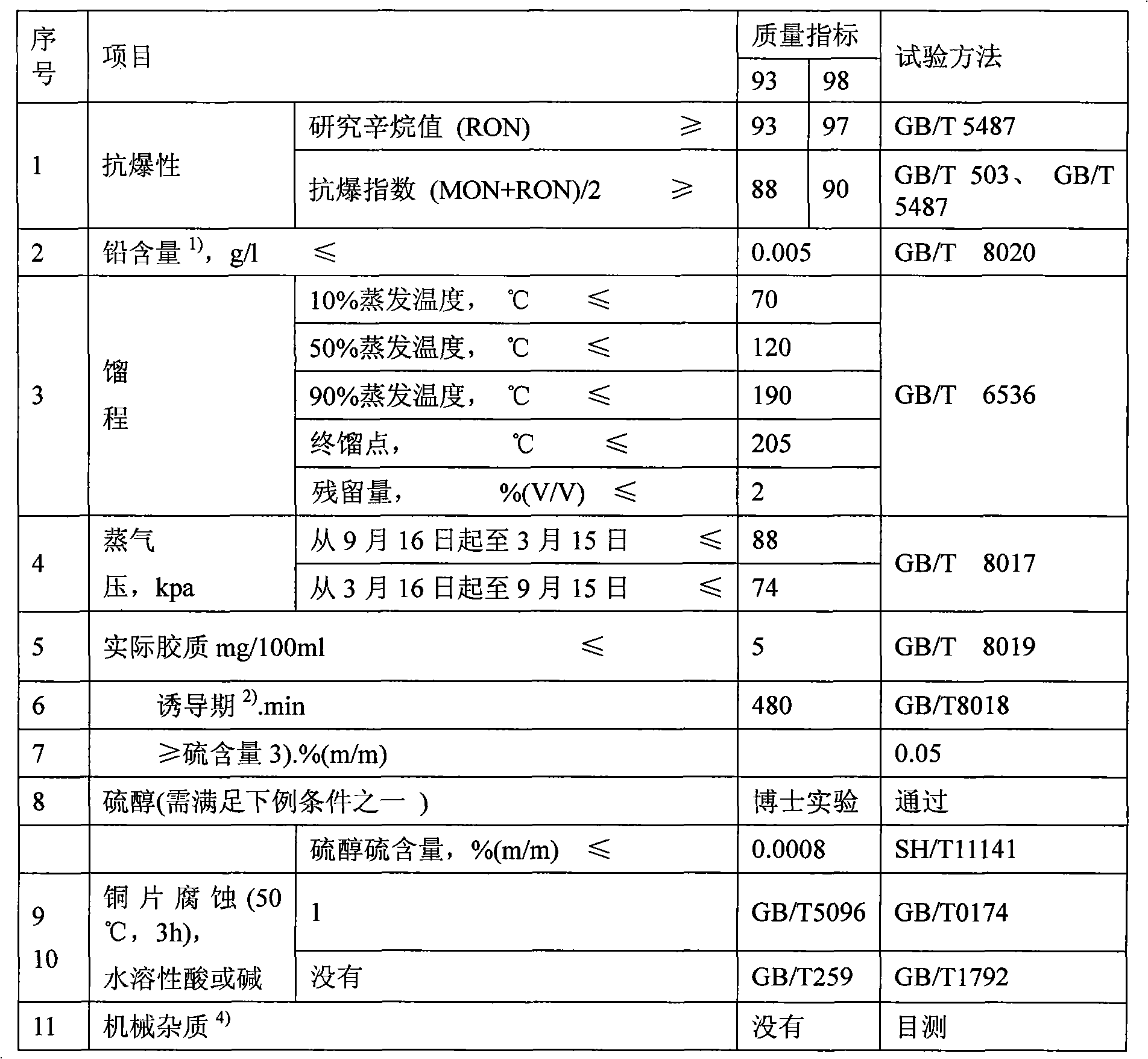

Alcohol ether gasoline used in new energy vehicles

InactiveCN101538491AReduce consumptionReduce pollutionLiquid carbonaceous fuelsNew energyLiquid fuel

The invention relates to a liquid fuel, and particularly a liquid carbonaceous fuel of the mixture of hydrocarbons and alcohol ether. The alcohol ether gasoline used in new energy vehicles comprises 25 to 85 percent of gasoline constituents and 15 to 75 percent of alcohol ether-major other chemical raw materials by weight percentage, wherein the components of the alcohol ether-major other chemical raw materials and the weight proportions thereof in the alcohol ether gasoline used in new energy vehicles are as follows: industrial methanol: 10 to 60 percent, n-hexane: 0 to 3 percent, isopropyl chloride: 0 to 1 percent, trichloroethylene: 0 to 1 percent, epichlorohydrin: 0.2 to 3 percent, bromoethanol: 0.2 to 2 percent, isodibutyl ether: 0.5 to 2 percent, ethylene glycol monobutyl ether: 0 to 1 percent, lauric acid : 0.4 to 2 percent, methyl chloroacetate: 0 to 4 percent, isopropyl nitrate: 0.2 to 4 percent, trimethyl phosphate: 0 to 3 percent, nitromethane: 0.1 to 1 percent, nitroethane: 0 to 1 percent, nitroguanidine: 0 to 3 percent, cyclopentadiene: 0 to 4 percent, and n-butylamine: 0 to 1 percent.

Owner:陈斌

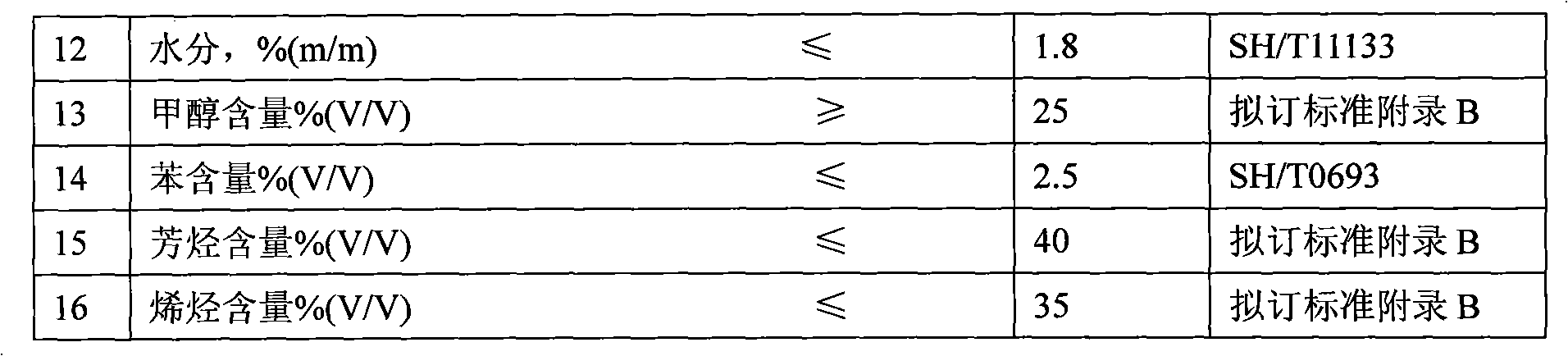

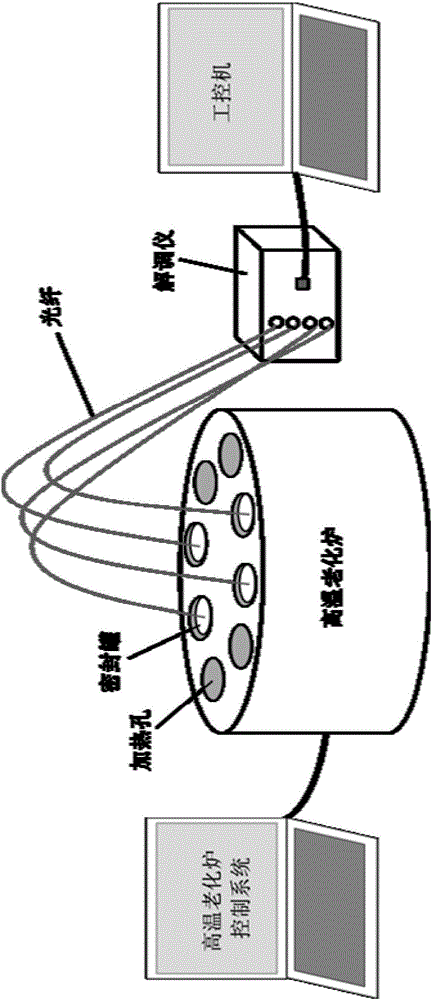

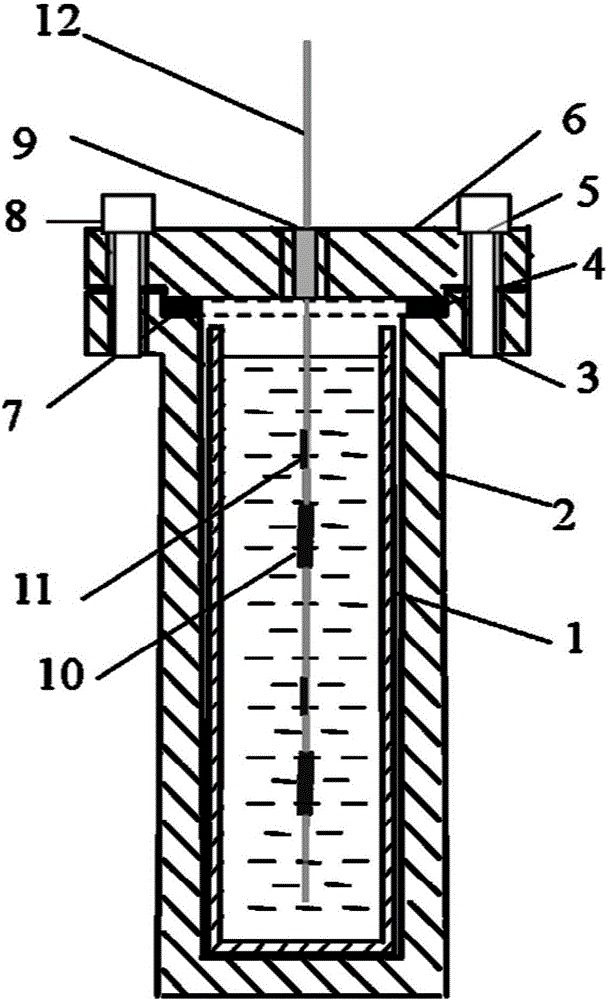

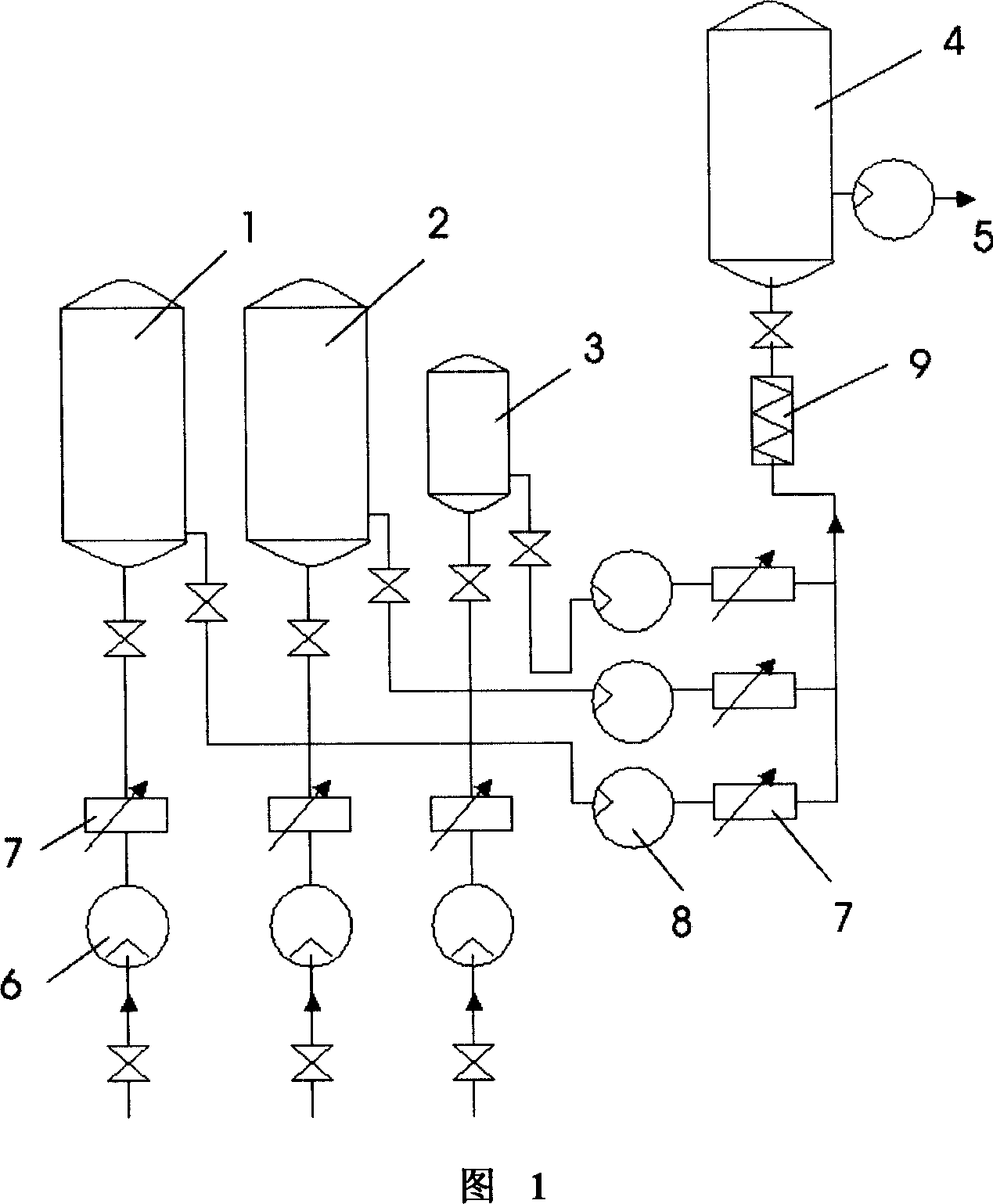

Lab high-temperature aging experiment system for gel state composite fuel

ActiveCN106645281AImprove securityPrevent leakageMaterial thermal coefficient of expansionMaterial heat developmentGratingEngineering

The invention discloses a lab high-temperature aging experiment system for gel state composite fuel, comprising a sealing tank, an opening type high-temperature aging system, and an optical fiber grid sensing system. The gel state composite fuel is placed in a sealing tank, a sensor of a fiber bragg grating is vertically embedded in the sample; an optical fiber end is connected with a demodulator, and the demodulator is connected with an industrial personal computer. The sealing tank is placed in the opening type high-temperature aging system to perform the aging test; the sensor collects the sample temperature and strain data in real time and draws up a monitoring curve, thus the temperature and strain change of the sample in the aging test can be observed. The system eliminates the explosive hidden trouble caused by heating and volatilizing isopropyl nitrate to air, and guarantees the safety of the thermal aging test of the el state composite fuel. The system monitors the temperature and strain change of the el state composite fuel aging sample in real time for the first time, and solves the problem that the sample information cannot be acquired timely for explosives and powders are under a 'black box' model in aging test. The invention is further used for the estimation of service life of the gel state composite fuel, and so on.

Owner:XIAN MODERN CHEM RES INST

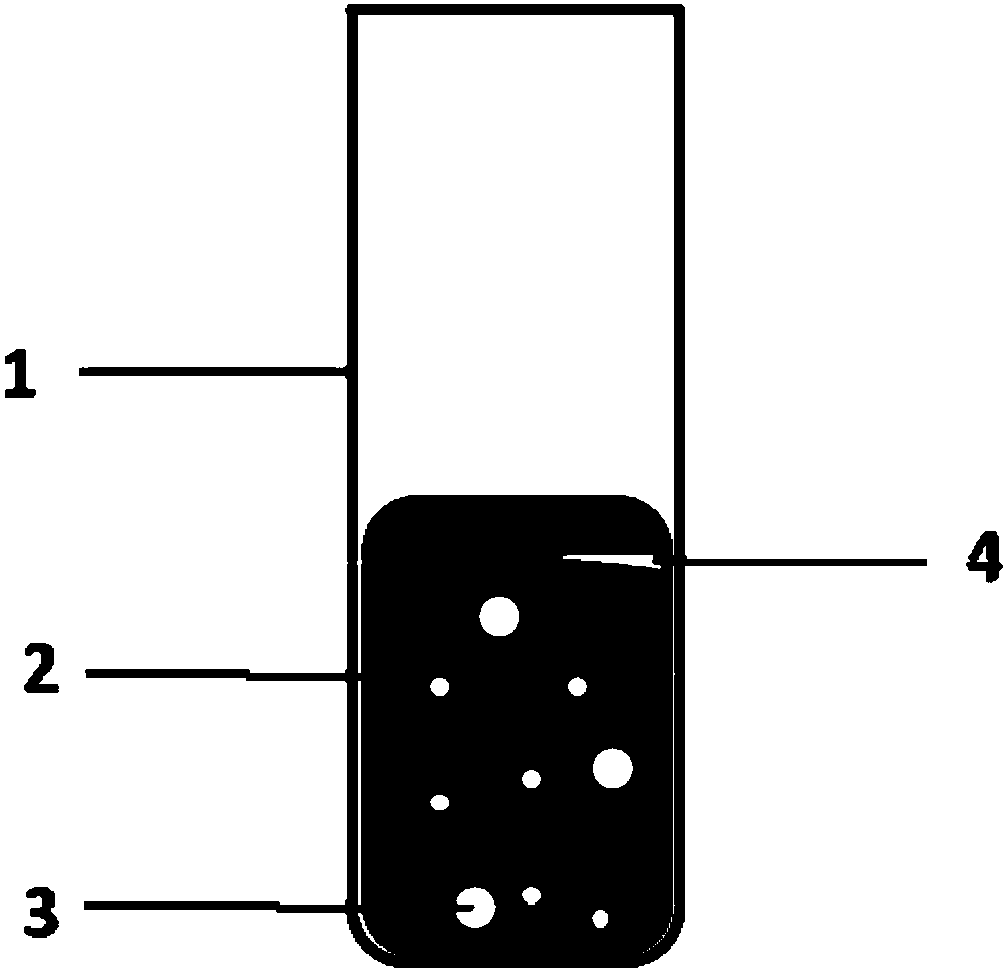

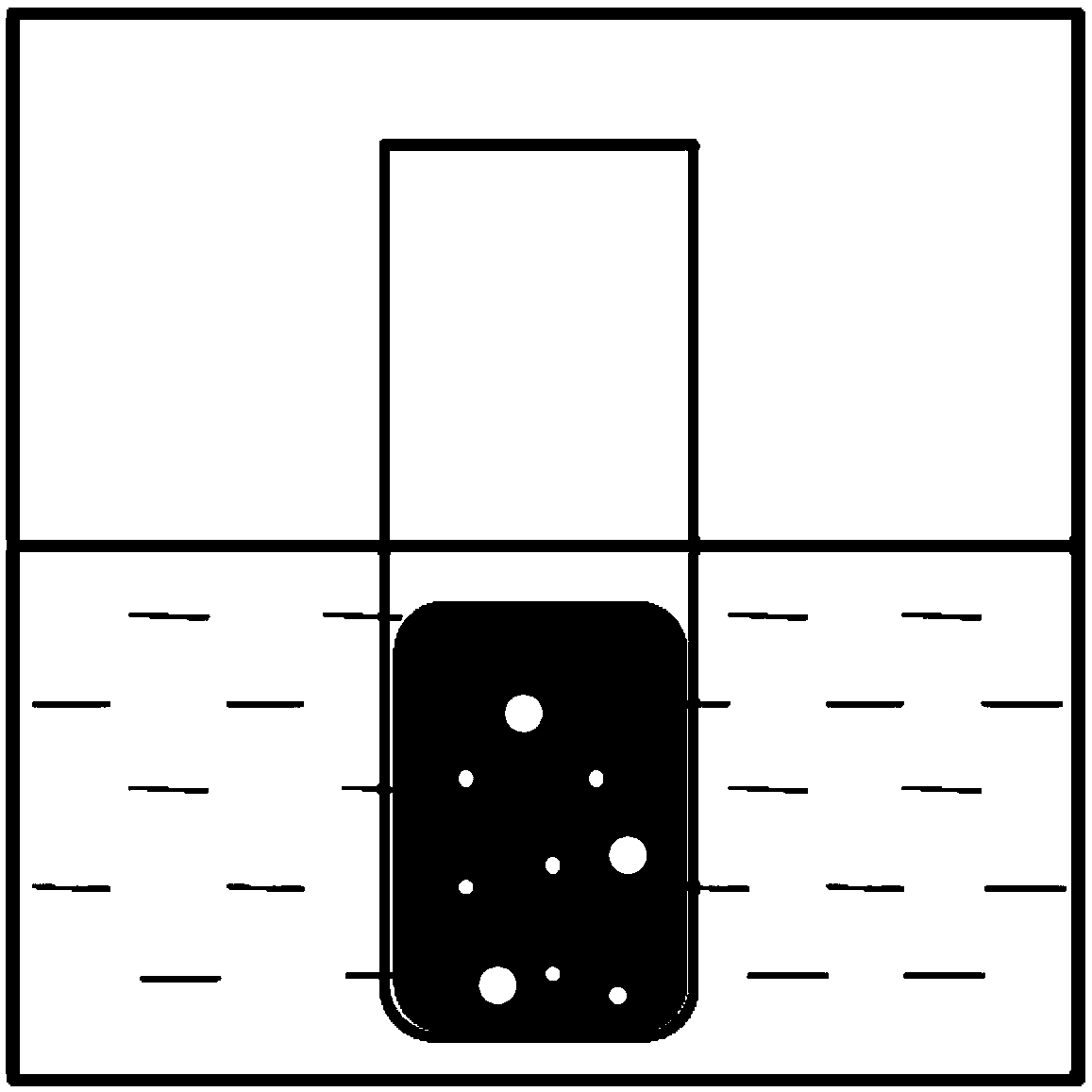

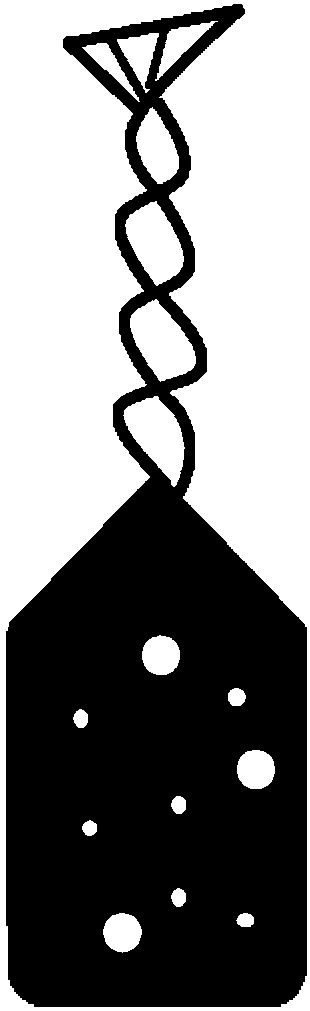

Expansibility characterization method of gel-state solid-liquid high-energy fuel filling explosive body

ActiveCN107702601AAvoid enteringEliminate potential safety hazardsAmmunition testingNitrile rubberHigh energy

The invention discloses an expansibility characterization method of a gel-state solid-liquid high-energy fuel filling explosive body. According to the method, isopropyl nitrate in a sample is replacedwith fuel hydrocarbon to be prepared into a simulated explosive; and the simulated explosive is wrapped by a nitrile rubber film bag, air exhausting is carried out in silicone oil, a bag opening is fastened through a rope and sealed, and the simulated explosive is prepared into a filling simulated explosive. The volumes of the silicone oil in a volume expansion coefficient tester at the temperature of 30 DEG C and the temperature of 60 DEG C are detected; the filling simulated explosive is placed into the silicone oil of the tester, and the volumes of the filling simulated explosive at the temperature of 30 DEG C and the temperature of 60 DEG C are obtained through volume changes of the silicone oil; and the volume expansion coefficient of the filling simulated explosive in the temperature zone from 30 DEG C to 60 DEG C is calculated. According to the method, volume expansibility of the heated gel-state solid-liquid high-energy fuel filling explosive under the full constraint condition can be subjected to characterization, the detection environment is closer to the actual charge condition, and basic data can be provided for determining the explosive filling process. The expansibility characterization method has the beneficial effects that the safety of the detection process is improved; and the structure of the simulated explosive is stable, and the detection accuracy is improved.

Owner:XIAN MODERN CHEM RES INST

High-clean methanol composite gasoline for vehicle and production thereof

The invention is about the high clearing methanol compound petrol which is composed of the methanol, the petrol, the acetone, the isopropyl ether, the isopropanol, the isoamylol, the tert-butyl alcohol and the synthetic addition agent. The addition agent is modulated by the ZnO, the Na2O2, the ferrum naphthenate and the isopropyl nitrate. The compound petrol can solve the problem of the corrosivity to the red copper and the swelling to the rubber. It can be mixed with the normal petrol arbitrarily and not need to change the structure of the engine, also it can remove the carbon and the colloid of the engine. The cost of the technique is low and the operability is high.

Owner:肖军

Smoke abatement anti-freeze agent for diesel fuel

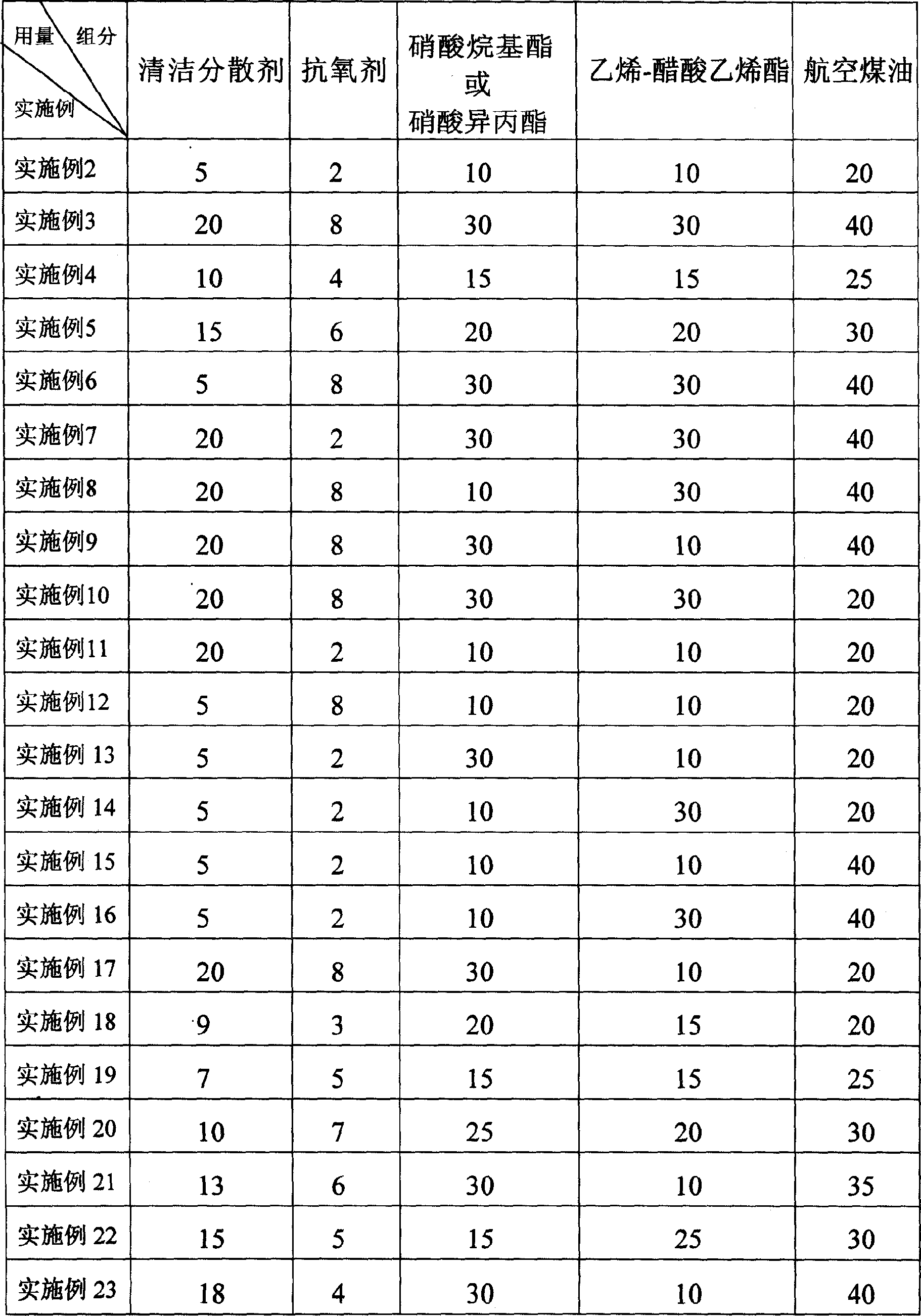

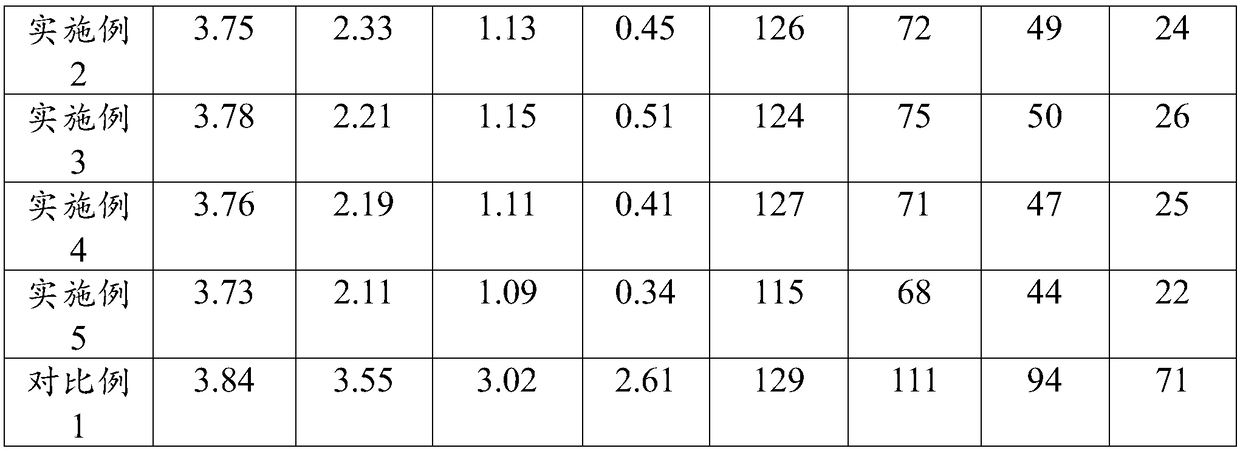

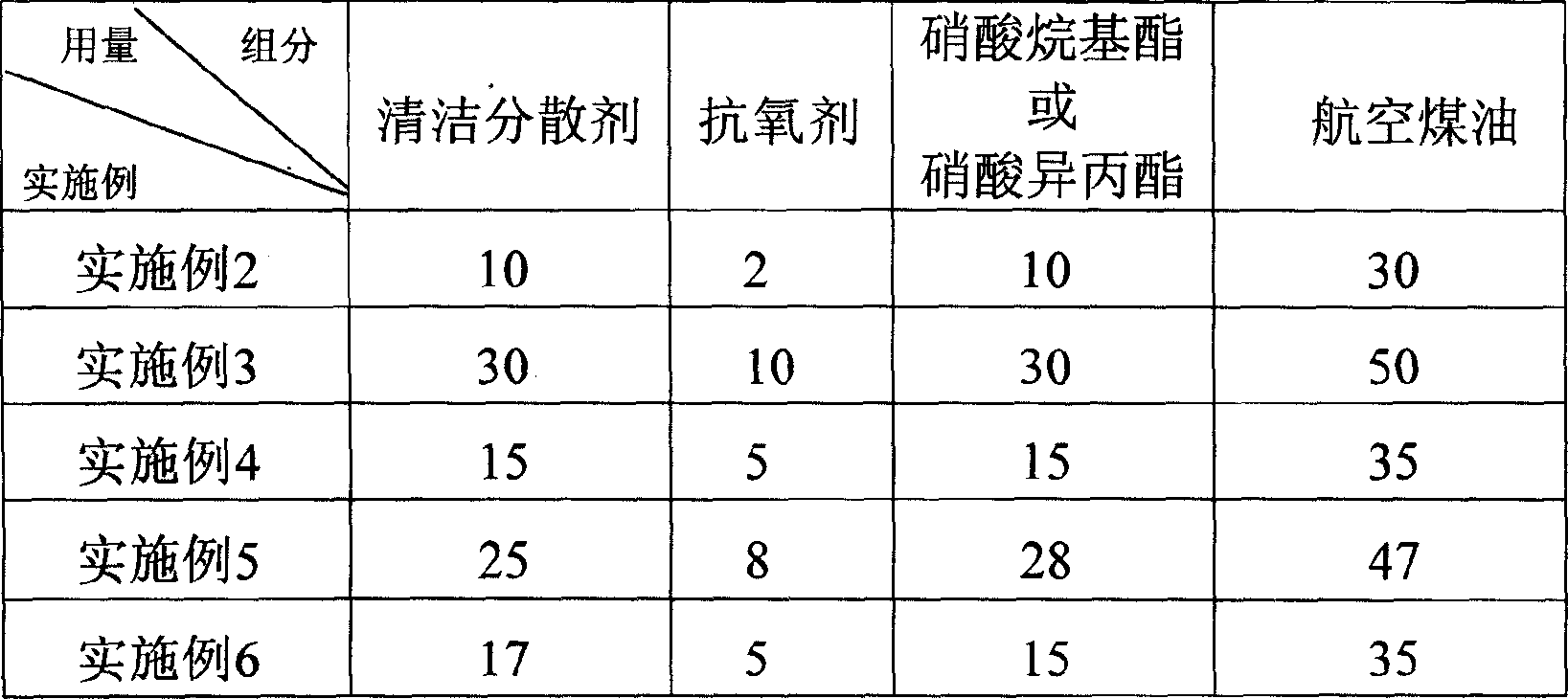

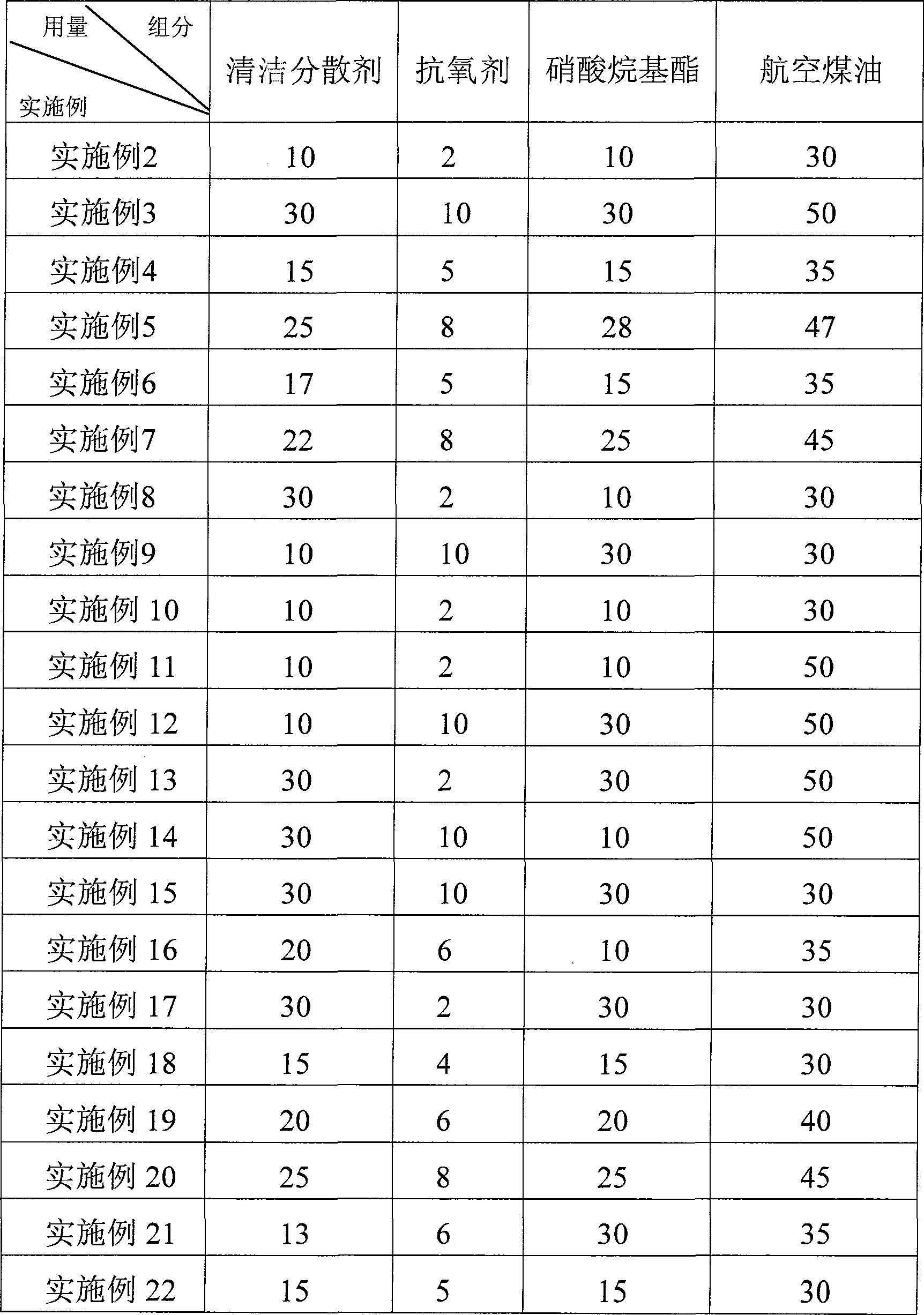

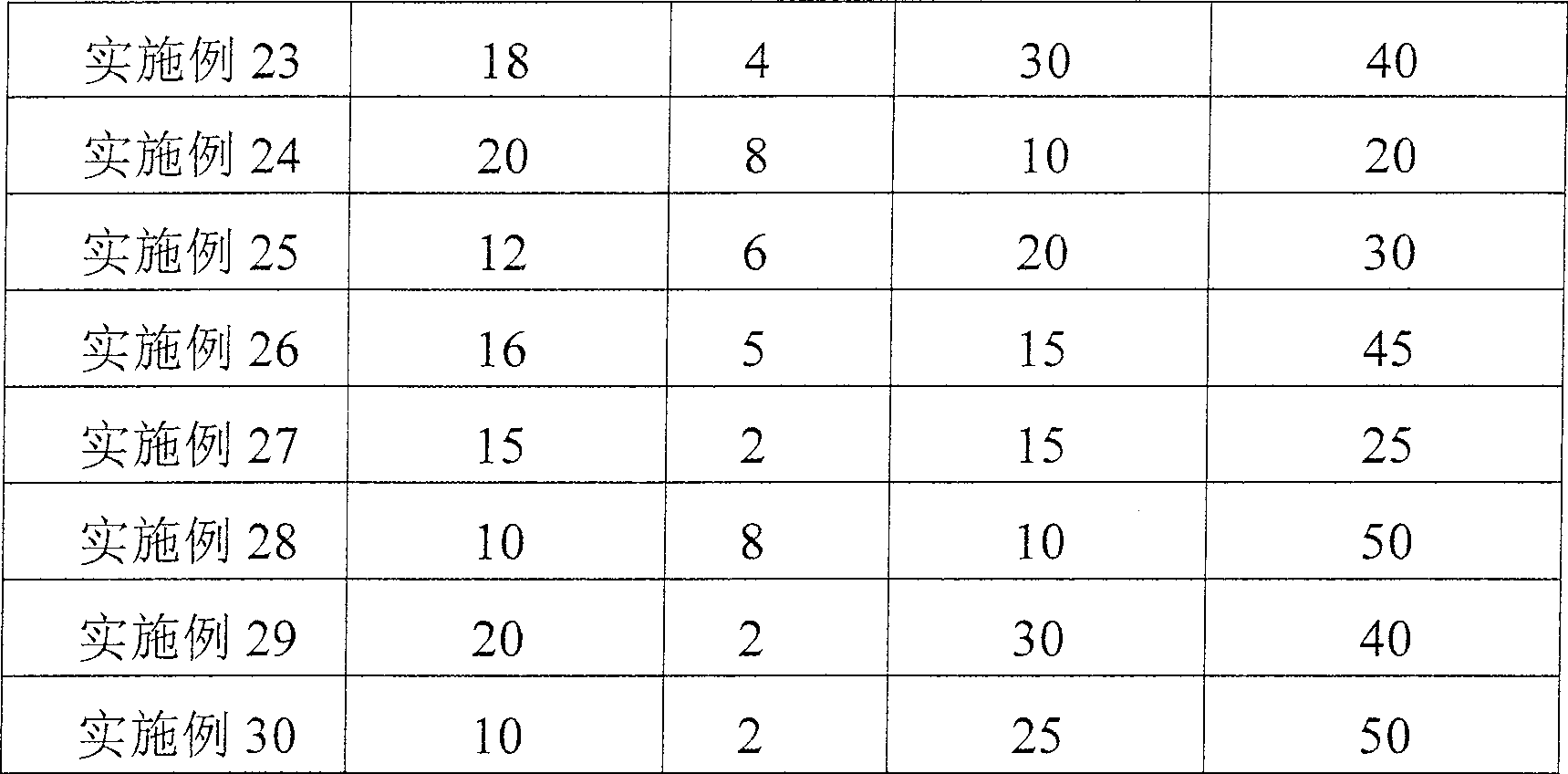

The invention provides an environment-friendly type diesel smoke abatement and anti-freeze agent for purifying emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate or ethylene / vinyl acetate and high grade plane kerosene through high-shearing mixing and emulsion process. The invention can realize good intensified smoke abatement property and fluidity for diesel under low-temperature.

Owner:牛云龙

Nano emulsified fuel addtiive and its perparing method

InactiveCN1587357ALower emission valueReduce concentrationLiquid carbonaceous fuelsPolyethylene glycolAlkylphenol

The present invention discloses nanometer emulsified fuel additive and its preparation process, and belongs to the field of liquid fuel additive technology. The fuel additive is prepared with the components including triethyl tetramine, diethyl ethanolamine, AE03 or AE04, alkylphenol ethoxylate, polyethylene glycol lauryl ether, ethylene glycol monomethyl ether, sorbitan oleate, fatty acid ester, isopropyl nitrate, cobalt naphthenate, acetone and ferrocene. It has an oil saving rate of 7-12 % and obvious pollution reducing effect.

Owner:谢学秀

Environment-friendly type methanol gasoline for vehicle

InactiveCN1923977ATo achieve a large proportion of accessionIncrease motivationLiquid carbonaceous fuelsKetoneTrimethylolpropane

The invention discloses a vehicle environmental-protective carbinol gasoline, which comprises the following parts: 1-40% carbinol, 50-89% basic oil, 0.1-0.3% ethane, 0.1-0.3% skellysolve B, 3-5% tertamyl methyl ether, 0.3-0.8% alcohol, 0.05-0.1% 2, 2-dimethylbutane, 0.1-0.3% tert-butanol, 0.1-0.3% normal propyl alcohol, 0.1-0.3% 2-ethyl(-1-) alcohol, 0.2-0.5% glycol, 0.1-0.15% 1, 3-dihydroxybutane, 0.3-0.8% neopentyl glycol, 0.1-0.15% 1, 6-hydroxylhexane, 0.2-0.5% trimethylolpropane, 0.3-0.5% pentaerythrite, 0.5-0.8% diisopropyl ether, 0.1-0.3% 2-ethyldioxy acetic ester, 0.1-0.3% isopropyl nitrate, 0.2-0.5% dimethyl ketone, 0.1-0.2% ethyl malonate, 0.05-0.2% diphenyl carbonate, 0.01-0.03% 102TB corrosion inhibitor and 0.01-0.03% 107PT anti-swelling agent.

Owner:顾杏泉

Liquid ecological gas and preparation method thereof

ActiveCN104673413AAlleviate the tight supply situationHigh calorific valueGaseous fuelsNitrocelluloseGlycerol

The invention discloses liquid ecological gas. A fuel namely the liquid ecological gas is prepared from the following components in percentage by mass: 15-25% of glycerol, 1-5.5% of polyacrylic ester, 17.5-23% of nitrocellulose, 23-43% of octanol, 6.5-14% of alkylbenzene sulfonate, 1-10% of polyisobutene, 0.5-4% of isopropyl nitrate, 2-7% of succinate imide and 1.5-7% of sodium hydroxide. The liquid ecological gas disclosed by the invention is high in combustion heat value, does not have smoke, toxicity and residues in a combustion process, is strong in environment friendliness and high in safety, and ensures that the problems that existing liquefied petroleum gas is insufficient in combustion and can bring potential hazards can be solved; the liquid ecological gas is simple in preparation method, does not need severe pressure or temperature conditions in a preparation process, is low in production cost, ensures that a finished product is pressure-free liquid, can be used for performing pressure-free transportation and storage, and ensures that the potential safety hazards of liquefied petroleum gas explosion caused by storing, transporting and using the liquefied petroleum gas under pressure conditions can be completely solved; and the liquid ecological gas can be transformed into a gas state from a liquid state by using an existing gasification device, and thus a current situation that the liquefied petroleum gas is in short supply can be alleviated.

Owner:许明华

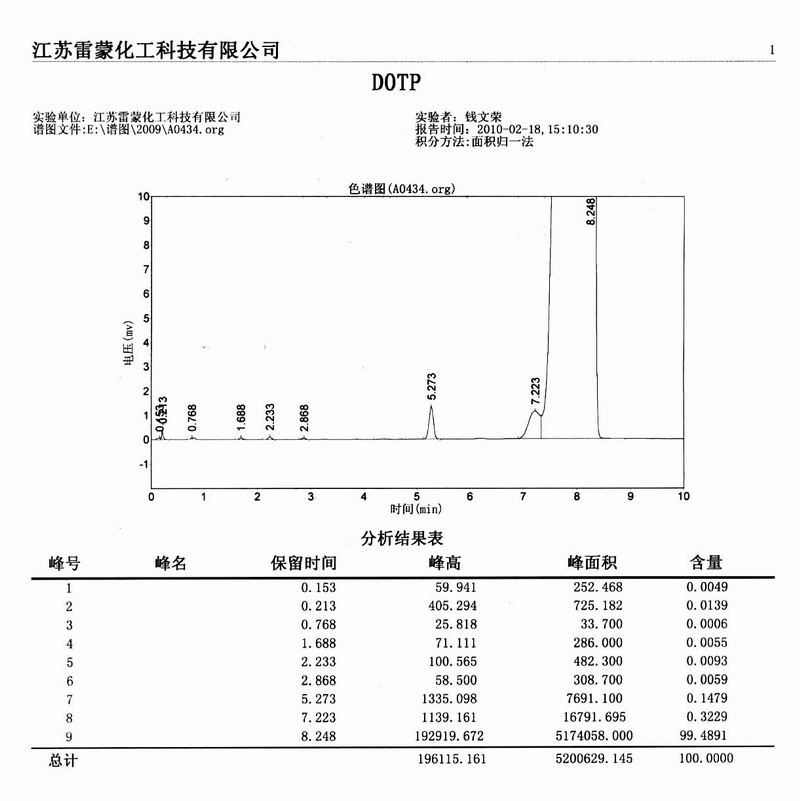

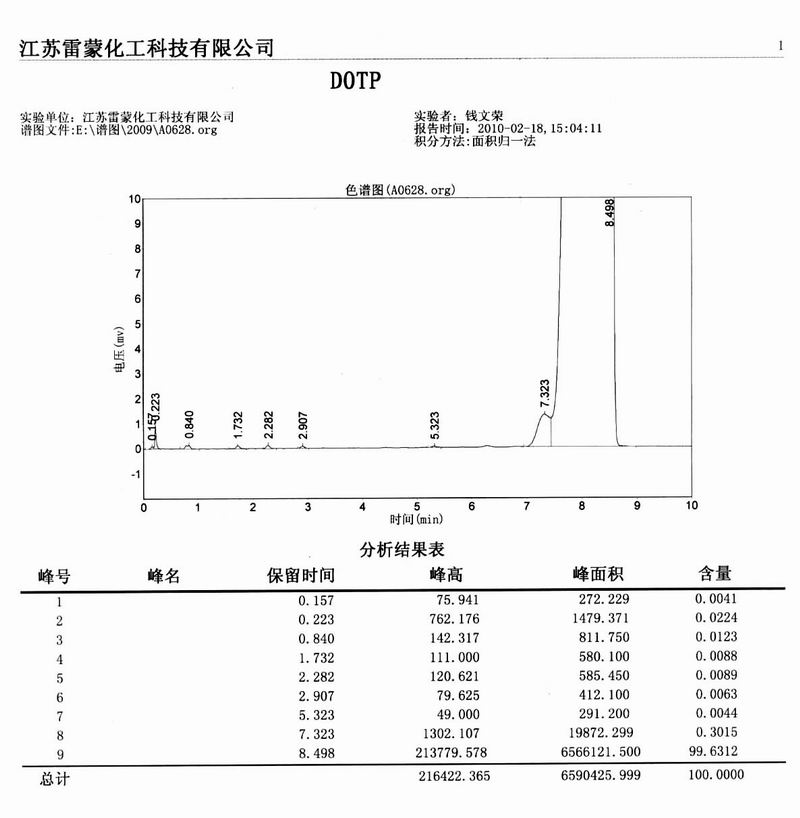

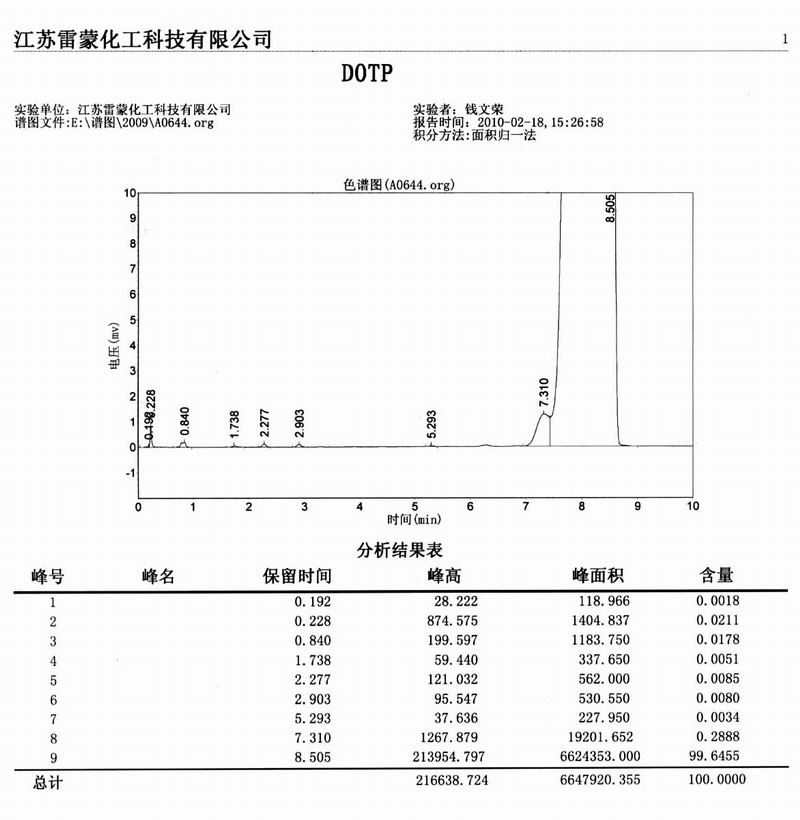

Catalyst used for production of high-purity terephthalic acid di(2-ethylhexyl) acrylate

InactiveCN101927181AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryTetraisopropyl titanate

Owner:江苏雷蒙新材料有限公司

Synthetic diesel oil

The invention relates to a synthetic diesel oil, belonging to the diesel oil technology field, comprising 24% of synthetic fuel agent, 48% of synthetic mother liquor and 28% of synthetic additive. The synthetic fuel agent is prepared by mixing trimethylbenzene, indenes and styrene. The synthetic mother liquor is prepared by mixing chinoline, quinoline, indole, biphenyl, alkene and washing oil. The synthetic additive is prepared by mixing No.0 diesel oil, isopropyl nitrate, sodium hydroxide. The synthetic diesel oil has simple production process, easy raw material obtaining, low production cost, low cold filter plugging point of -19.2 DEG C, little harmful gas such as CO discharged during combustion, stable oil performance, no deterioration for long term storage.

Owner:李金城 +1

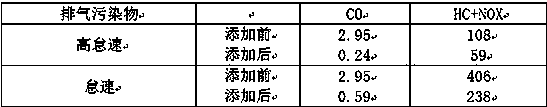

Energy-saving and combustion-supporting automotive tail gas gasoline detergent and preparation method thereof

InactiveCN108949260AGood miscibilityEasy to prepareLiquid carbonaceous fuelsFuel additivesLow speedCerium

The invention discloses an energy-saving and combustion-supporting automotive tail gas gasoline detergent and a preparation method thereof. The energy-saving and combustion-supporting automotive tailgas gasoline detergent is prepared from the following raw materials in parts by weight: 10 to 15 parts of methanol, 3 to 6 parts of ethyl acetate, 5 to 9 parts of cerium naphthenate, 2 to 10 parts ofpolyethylene polyamine, 8 to 15 parts of fatty alcohol, 6 to 16 parts of glycerol tristearate, 3 to 7 parts of isopropyl nitrate, 6 to 11 parts of diisopropyl ether, 2 to 5 parts of nano loaded type activated carbon, 7 to 23 parts of deionized water, 0.5 to 1 part of an antioxidant stabilizer, and 1 to 1.5 parts of N,N-dimethyl acetamide. The miscibility of the gasoline detergent and the gasolineis good, the preparation method is simple, stable combustion supporting can be achieved under the situation that a gasoline engine operates at low speed and low temperature or at high speed and high temperature, the power is improved, a baffled sense is avoided, the corrosivity is low, the loss is low for the engine, the adsorption degradation efficiency of sulfide, nitrogen oxide and inhalable particles produced by burning of gasoline is greatly improved, and the purity degree of the automotive tail gas is purified.

Owner:安徽绿色精灵新能源科技有限公司

Catalytic detersive of diesel fuel

The invention provides an environment-friendly type diesel catalysis detersive for cleaning emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate and high grade plane kerosene through high-shearing mixing and emulsion process. The agent can improve combustion efficiency according to the combustion conditions.

Owner:牛云龙

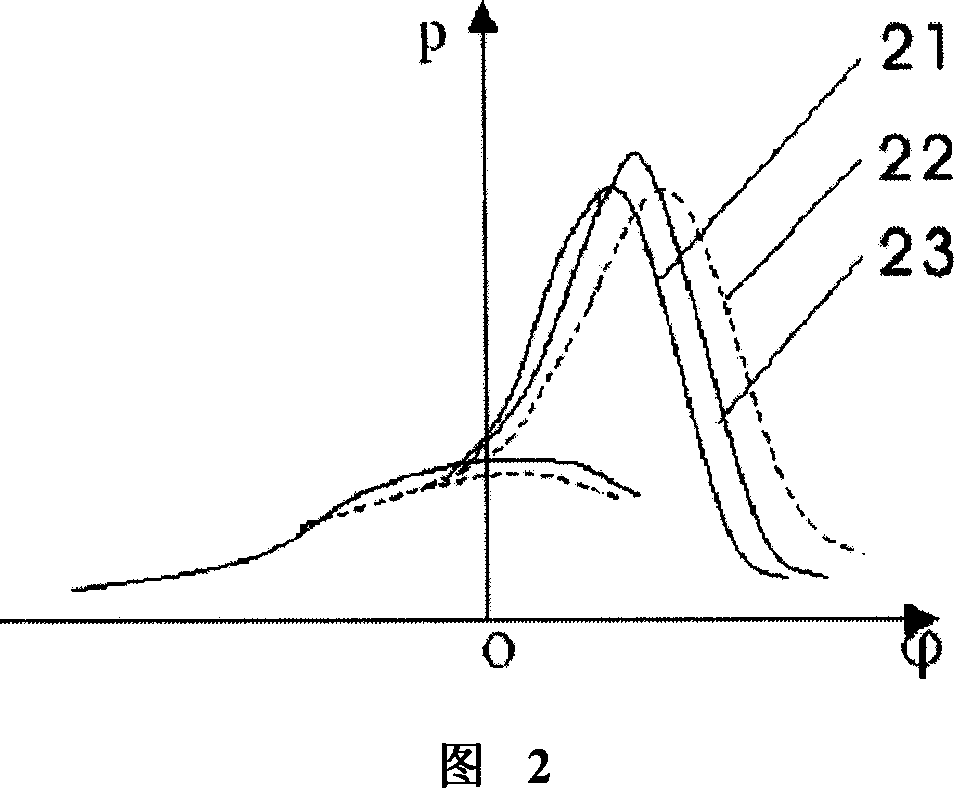

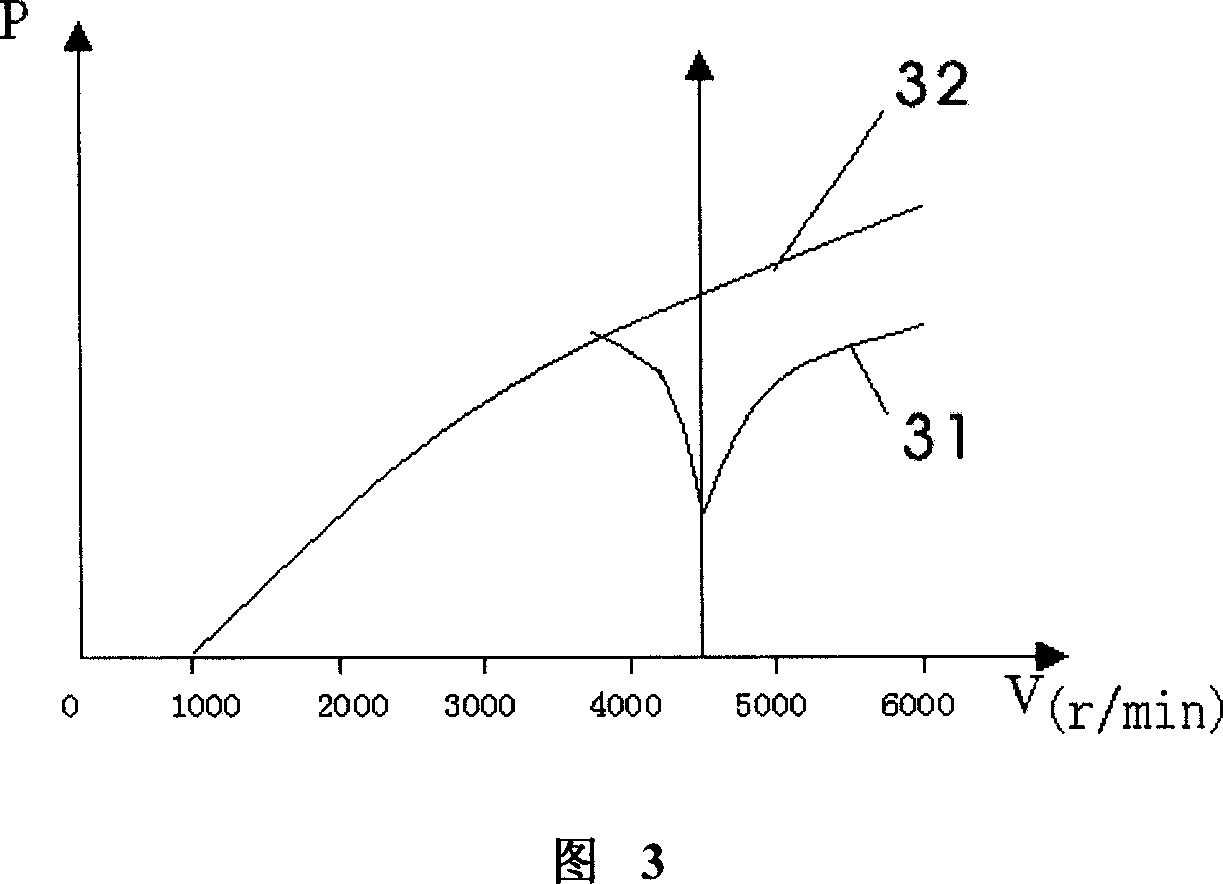

Catalytic detersive of diesel fuel

InactiveCN100482770CReduce black smoke emissionCatalytic persistenceLiquid carbonaceous fuelsEmulsionNitrite

The invention provides an environment-friendly type diesel catalysis detersive for cleaning emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate and high grade plane kerosene through high-shearing mixing and emulsion process. The agent can improve combustion efficiency according to the combustion conditions.

Owner:牛云龙

Automobile exhaust cleaning agent and preparation method thereof

InactiveCN108587708AImprove solubilityHigh calorific valueLiquid carbonaceous fuelsFuel additivesCombustion chamberCarbon deposit

The invention discloses an automobile exhaust cleaning agent and a preparation method thereof. The automobile exhaust cleaning agent comprises the following components in parts by weight: 80.00-90.00parts of methanol, 1.50-2.00 parts of isopropyl nitrate, 1.00-1.50 parts of oleic acid, 1.50-1.80 parts of higher aliphatic alcohol, 1.30-1.60 parts of propylene glycol, 1.30-1.80 parts of dodecanol,1.50-2.00 parts of xylene, 3.00-4.00 parts of polyetheramine, and 2.00-2.50 parts of PIBA. The automobile exhaust cleaning agent can clean an oil road, and can clean the carbon deposit from a combustion chamber, the carbon deposit is combusted during a gasoline combustion process, so that discharge is reduced, and the tail gas reaches a standard. The automobile exhaust cleaning agent has the advantages that raw materials are easily available, the preparation is simple, the production cost is low, the automobile exhaust cleaning agent can be added in gasoline for usage, can directly substitutethe gasoline for usage, and has good social and economic benefits.

Owner:曹玉会

Novel composite fuel oil

InactiveCN104726148ARaw materials are widely availableLow costLiquid carbonaceous fuelsFuel additivesKerosenePhosphoric acid

The invention discloses novel composite fuel oil. The fuel oil is prepared from the following components in parts by weight: 30-50 parts of crude benzene, 5-10 parts of gasoline, 40-60 parts of cracking kerosene, 10-20 parts of sulfonated oil, 0.03-0.06 part of ferrocene, 1-3 parts of isopropyl nitrate, 0.3-0.8 part of sodium dialkyl sulfo-succinate, 0.1-0.3 part of ethylene glycol monomethyl ether, 0.1-0.3 part of disodium hydrogen phosphate, 0.1-0.3 part of sodium hydroxide, 0.01-0.03 part of succinimide, 2-4 parts of a cetane number improver, 5-10 parts of a reducing stabilizer, 10-20 parts of a viscosity modifier and 0.1-0.3 part of a composite additive. Compared with the prior art, the novel composite fuel oil has the advantages of wide and easily available raw materials, relatively low cost, simple preparation, no refining requirement, safety and convenience in use, low fuel consumption, high combustion value and sufficient combustion without carbon deposition, and is in accordance with environment-friendly requirements.

Owner:长沙永鑫新能源科技有限公司

Anti-scaling compounded anti-freezing fluid for locomotive

The invention discloses anti-scaling compounded anti-freezing fluid for a locomotive. The anti-freezing fluid is prepared from the following ingredients in percentage by weight: 40-70% of glycerol, 0.05-1% of sodium metasilicate, 0.4-2.5% of sodium benzoate, 0.4-2.5% of calcium formate, 0.3-1.5% of fulvic acid, 0.5-3.6% of isopropyl nitrate, 10-15% of silicone, 0.1-0.5% of potassium permanganate, 1-8% of glycerine and the balance of deionized water. The anti-freezing fluid with good stability, disclosed by the invention, has the advantages that a system of a formula without phosphate radicals is adopted; in the formula, molybdate and organic acid cooperate with each other, jointly provide protection for metal and are assisted with sodium nitrate, so as to provide long-term durable metal corrosion resistance; in the formula, the application of a large volume of sebacic acid exerts a good addition effect on the corrosion resistance of the metal.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Automobile exhaust cleaning agent

InactiveCN108479390AEffectively purify exhaust gasImprove protectionGas treatmentDispersed particle separationHigh carbonCleansing Agents

The invention relates to the technical field of automobile exhaust pollution control and in particular discloses an automobile exhaust cleaning agent. The automobile exhaust cleaning agent is preparedfrom ethyl propyl nitrate, N,N-dimethyl-acetamide, ethylene glycol monomethyl ether, diisopropyl ether, fatty alcohol, laurinol, high carbon number fatty alcohol, coarse polyhydric alcohols, glycerinpalm kernel fatty acid ester and glycerin aconitate according to a certain weight ratio. The automobile exhaust cleaning agent disclosed by the invention is readily available in raw materials, simplein preparation, low in production cost and capable of effectively purifying automobile exhaust, contributes to protecting the environment and reducing pollution and is suitable for wide popularization and application.

Owner:徐新民

Environmental-protection alcohol diesel

InactiveCN104927946AEase market pressureImprove qualityLiquid carbonaceous fuelsBiodieselPetrochemical

The invention discloses environmental-protection alcohol diesel, and belongs to the synthetic diesel technical field. The environmental-protection alcohol diesel is composed of the following components by the weight percentage: 35-50% of petrochemical diesel, 25-30% of modified biodiesel, 15-20% of ethanol, 10-15% of methanol, and 0.05-0.5% of an additive, wherein the additive includes an oil soluble agent, methyl tert-butyl ether, fatty alcohol polyoxyethylene ether, petroleum calcium sulfonate, isopropyl nitrate, sodium hydroxide and diesel. The environmental-protection alcohol diesel saves non-renewable petroleum resources, alleviates the pressure of diesel markets, reduces environmental pollution, effectively improves the diesel quality, has no side effect, and is stable in performance and sufficient in calorific value.

Owner:康建国

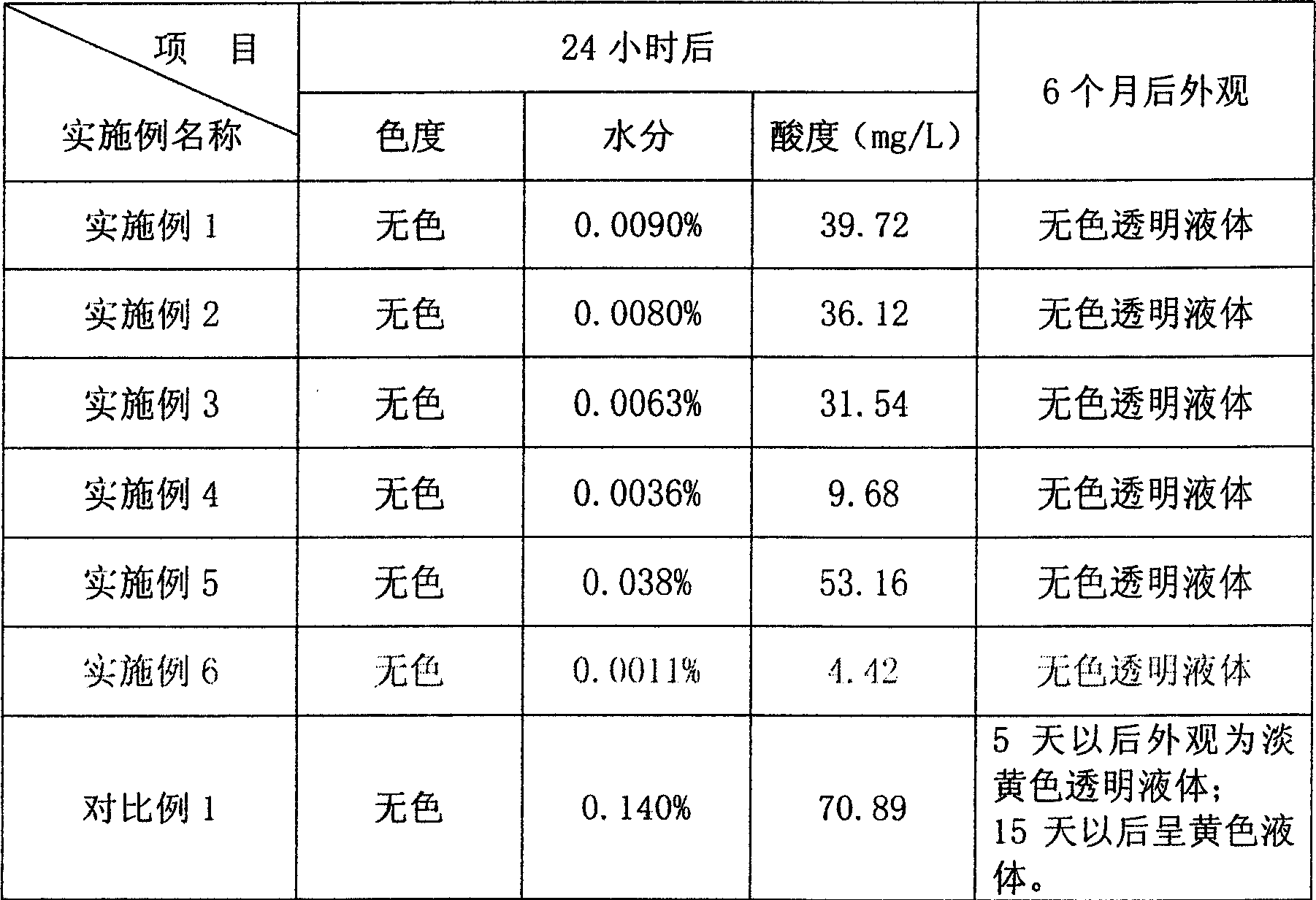

Storage method of iso-propyl nitrate

InactiveCN1631872AEasy to separateOrganic chemistryOrganic compound preparationMolecular sievePropyl nitrate

Disclosed is a method to store isopropyl nitrate, which store isopropyl nitrate and 4A molecular sieve together. Without any other special equipment, the 4A molecular sieve is used to be storage stabilizer of isopropyl nitrate, and it can be separated from the product, further mare, it can be regenerated and reused for many times, resulting in the storing period being prolonged from less than a week to more than half a year.

Owner:ZHEJIANG UNIV OF TECH

Composite gasoline additive

InactiveCN107746731AImprove the lubrication effectReduce wearLiquid carbonaceous fuelsFuel additivesCyclohexeneKetone

The invention provides a composite gasoline additive, comprising 70-85 parts of ethanol; 22-27 parts of brown humic acid; 8-10 parts of diisopropyl ether; 15-13 parts of isopropanol; 12-17 parts of methyl isobutyrate 8-10 parts of isooctane; 5-6 parts of polyisobutylamine; 7-8 parts of methyl ethyl ketone; 4-8 parts of di-n-butyl phosphite; 6-7 parts of hexamethylenetetramine; 5-6 parts of cyclohexyl glycidyl ether; 7-12 parts of cyclohexene; 4-8 parts of isopropyl nitrate; 5-6 parts of amyl biscyclohexyl ketone; 7-8 parts of fatty acid ethyl ester; 4-8 parts of hexyl alcohol; 2-6 parts of oleic acid; 5-6 parts of lanolin; 5-6 parts of oleic acid amide; 4-8 parts of p-xylene; 4-8 parts of tetrahydrofuran; share. The invention enhances fuel combustion efficiency and achieves the purpose of energy saving.

Owner:魏崇振

Acne cream

InactiveCN102068396AGood effectNo side effectsCosmetic preparationsToilet preparationsLanolinStearic acid

The invention provides an acne cream which is composed of kieselguhr, kaolin, activated carbon, glycerol monostearate, cetanol lactate, stearic acid, lanolin-isopropyl nitrate, propyl p-hydroxybenzoate, propylene glycol, deionized water, alcohol, almond meal and chitin. The acne cream has the advantages of obvious drug effect, no side effect, abundant raw material resource and low production cost.

Owner:戚冬梅

Automobile exhaust cleaning agent and preparation method thereof

InactiveCN110699128AEasy to makeReduce manufacturing costLiquid carbonaceous fuelsFuel additivesGlycerolCleansing Agents

Owner:吴伟

Preparation method of tail gas cleaning agent

InactiveCN109929614AAccelerated corrosionInhibition of swellingSolid fuelsLiquid carbonaceous fuelsKetoneCleansing Agents

The invention relates to the field of gasoline additives in the energy industry, in particular to a preparation method of a tail gas cleaning agent. The method comprises the following steps: S1, selecting raw materials; S2, mixing the raw materials of methanol, base oil, ethane, n-hexane, methyl tert-butyl ether, ethanol, 2,2-dimethylbutane, tert-butanol, n-propanol, 2-ethyl-1-ethanol, glycol, 1,3-dihydroxybutane, neopentyl glycol, 1,6-dihydroxyhexane, trimethylolpropane, pentaerythritol, diisopropyl ether, 2-diethoxy ethyl acetate, isopropyl nitrate, dimethyl ketone, ethyl malonate and diphenyl carbonate into a reaction kettle, and mixing and stirring all the components to form a blend; and S3, sequentially adding 102TB corrosion inhibitor and 107PT anti-swelling agent into the blend, andmixing and stirring all the components to obtain the gasoline additive. Compared with the prior art, the device is clean, environmentally friendly, sufficient in combustion, sufficient in fuel oil atomization and more sufficient in combustion, and carbon on the surface area of the carbon deposition cleaning valve is removed.

Owner:刘云岭

High-efficiency fuel additive

InactiveCN107686753AImprove combustion efficiencyAvoid pauseLiquid carbonaceous fuelsFuel additivesCombustion chamberInlet valve

The invention relates to a high-efficiency fuel additive. The high-efficiency fuel additive is prepared from the following components in parts by mass: 11 to 19 parts of biomass alcohol, 6 to 15 partsof normal octane, 8 to 10 parts of benzotriazole, 10 to 14 parts of butyl acetate, 9 to 11 parts of isopropyl nitrate, 4 to 16 parts of ethylene glycol saturated amide, 3 to 5 parts of ethylene glycol ethyl ether, 15 to 20 parts of methyl tert-butyl ether and 40 to 50 parts of absolute ethyl alcohol. The high-efficiency fuel additive disclosed by the invention has an effective chemical action forcleaning an integral fuel system, is suitable for a novel direct injection fuel system and can be used in engines with any types such as gasoline and diesel oil for removing precipitates from a combustion chamber and a gas inlet valve; and by only needing to pour the high-efficiency fuel additive in a fuel tank, halting is effectively prevented, the combustion efficiency and horsepower of the fuel are improved, and emission is reduced.

Owner:刘秀梅

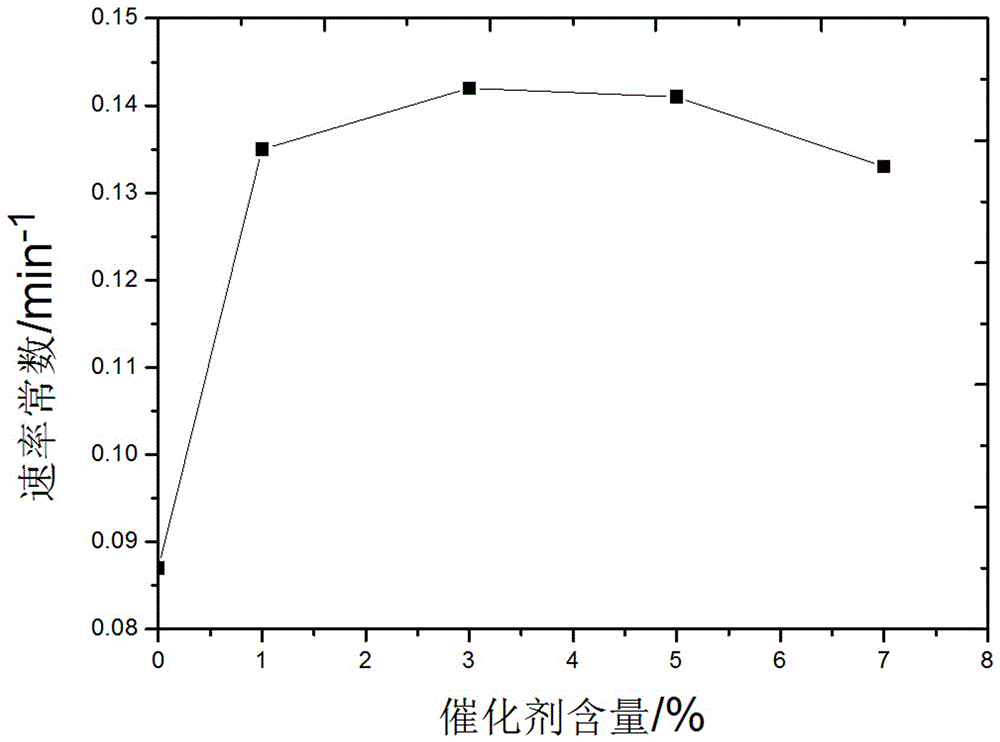

Method for rapidly disposing isopropyl nitrate and application of method

ActiveCN106630091AAvoid smallSimple reaction conditionsWater contaminantsBlastingPropyl nitrateNuclear chemistry

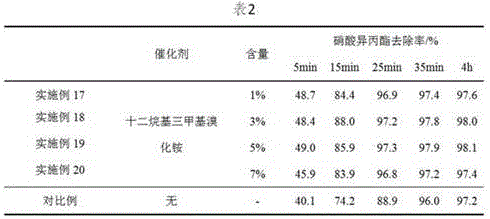

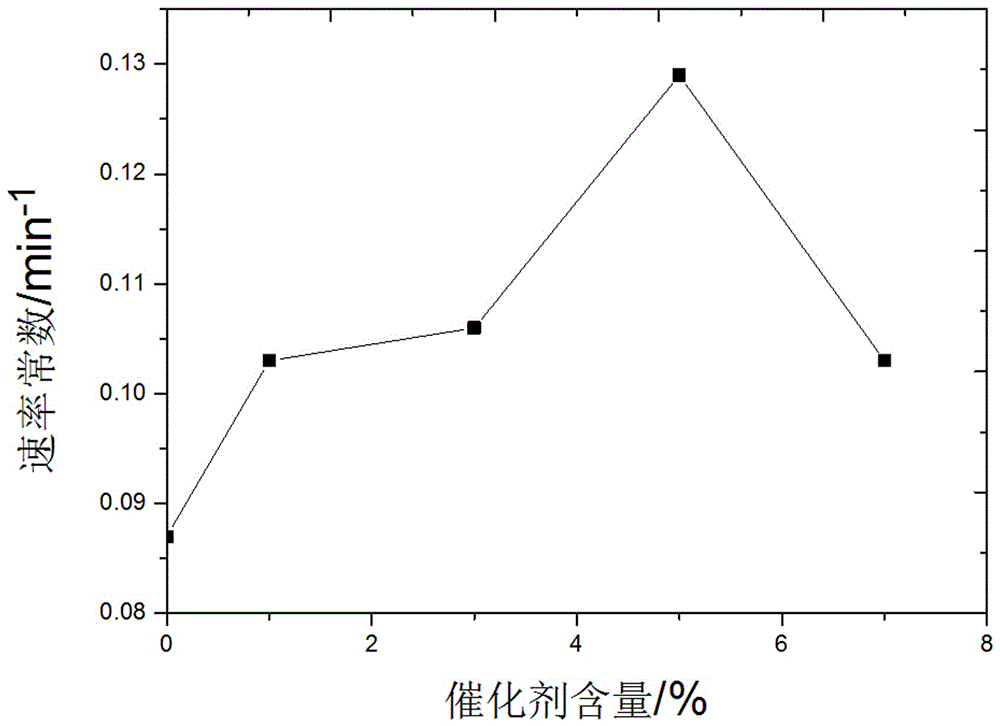

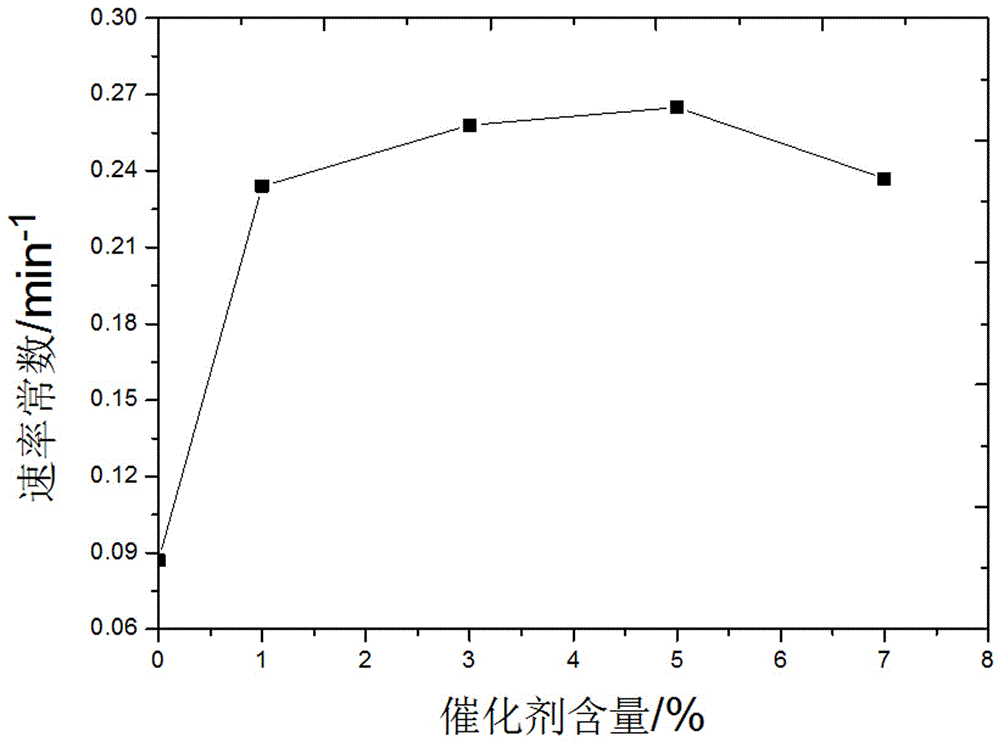

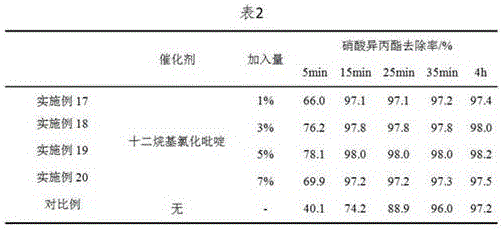

The invention relates to the technical field of safety disposal of nitrate energetic materials, and particularly discloses a method for rapidly disposing isopropyl nitrate and application of the method. The method comprises the following steps: performing mixing reaction on the isopropyl nitrate or an aqueous solution thereof and an excessive sodium sulfide solution, and adding a catalyst, namely, dodecyltrimethylammonium bromide, to catalyze reducing reaction of the isopropyl nitrate, wherein the molar weight of the added catalyst is 1 to 7 percent of the molar weight of the isopropyl nitrate. The method can be used for scrap disposal of isopropyl nitrate-containing arms and ammunition. According to the method, the isopropyl nitrate can be rapidly deenergized and decomposed, and the method is low in time consumption, high in removal rate and safety, simple in control condition and easy to operate.

Owner:NO 63908 TROOPS PLA

Rapid processing method of isopropyl nitrate, and applications thereof

ActiveCN106630092AAvoid smallSimple reaction conditionsWater contaminantsBlastingDecompositionRapid processing

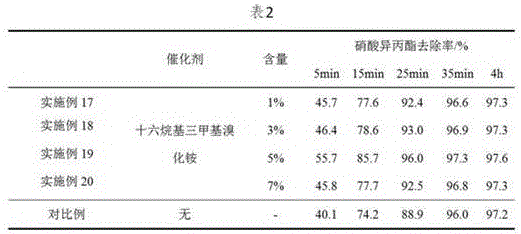

The invention belongs to the technical field of safety disposal of nitric acid ester energetic materials, and more specifically discloses a rapid processing method of isopropyl nitrate, and applications thereof. The rapid processing method comprises following steps: isopropyl nitrate or an aqueous solution of isopropyl nitrate is mixed with an excess sodium sulfide solution for reaction; catalyst hexadecyl trimethyl ammonium bromide is added to catalyze reduction reaction of isopropyl nitrate, wherein the molar amount of the added catalyst accounts for 1 to 7% of that of isopropyl nitrate. The rapid processing method can be used for scrap disposition of arms and ammunition containing isopropyl nitrate, is capable of realizing rapid deenergization decomposition processing of isopropyl nitrate, and is short in time consuming, high in removing rate; control conditions are simple; operation is convenient; and safety is high.

Owner:NO 63908 TROOPS PLA

Rapid processing method of isopropyl nitrate, and applications thereof

ActiveCN106630093AAvoid smallSimple reaction conditionsWater contaminantsWater/sewage treatment by reductionDecompositionRapid processing

The invention belongs to the technical field of safety disposal of nitric acid ester energetic materials, and more specifically discloses a rapid processing method of isopropyl nitrate, and applications thereof. The rapid processing method comprises following steps: isopropyl nitrate or an aqueous solution of isopropyl nitrate is mixed with an excess sodium sulfide solution for reaction; catalyst dodecylpyridinium chloride is added to catalyze reduction reaction of isopropyl nitrate, wherein the molar amount of the added catalyst accounts for 1 to 7% of that of isopropyl nitrate. The rapid processing method can be used for scrap disposition of arms and ammunition containing isopropyl nitrate, is capable of realizing rapid deenergization decomposition processing of isopropyl nitrate, and is short in time consuming, high in removing rate; control conditions are simple; operation is convenient; and safety is high.

Owner:NO 63908 TROOPS PLA

Safe and efficient processing method of iso-propyl nitrate

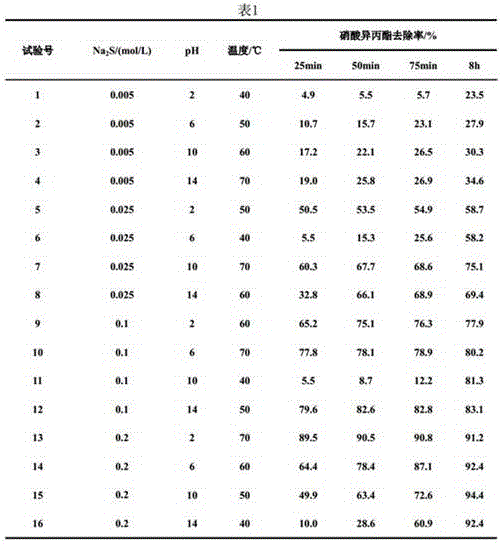

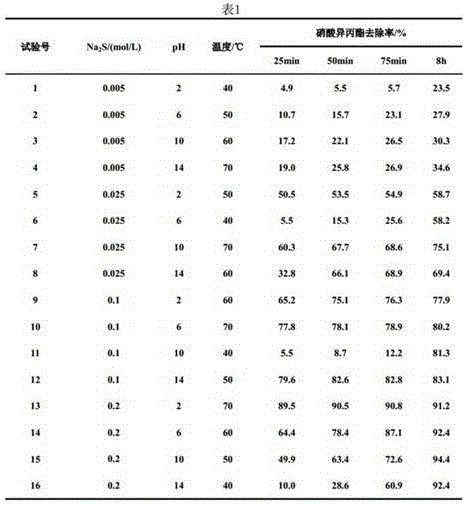

InactiveCN106186266AAvoid smallSimple reaction conditionsWater contaminantsWater/sewage treatment by reductionWastewaterSafe handling

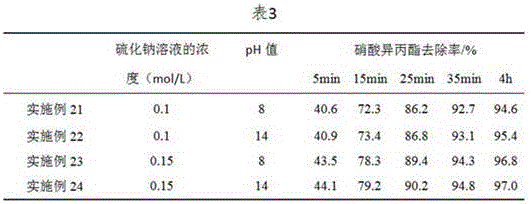

The invention relates to the technical field of nitrate ester energy material safety processing, in particular to the technical field of treatment of wastewater containing energy materials, and particularly discloses a safe and efficient processing method of iso-propyl nitrate. The method includes the following steps that iso-propyl nitrate or an aqueous solution of iso-propyl nitrate is added into an excessive sodium sulfide aqueous solution with the concentration of 0.1-0.2 mol / L for reaction, the pH of the reaction solution is controlled to be 6-14, and the temperature is controlled to be 50-70 DEG C. By means of the method, iso-propyl nitrate and the aqueous solution of iso-propyl nitrate can be efficiently and safely processed so as to be decomposed, and the method has the advantages of being high in processing ability, high in efficiency and removal rate, easy to operate, and easy to implement.

Owner:NO 63908 TROOPS PLA

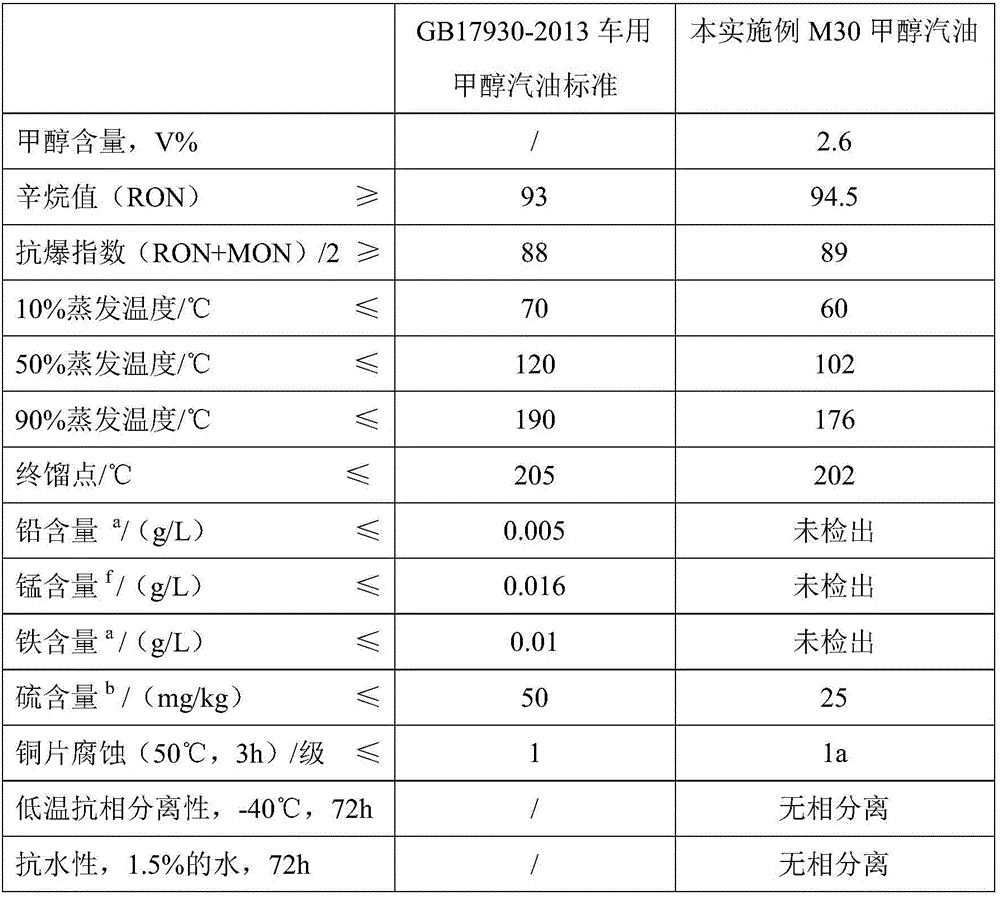

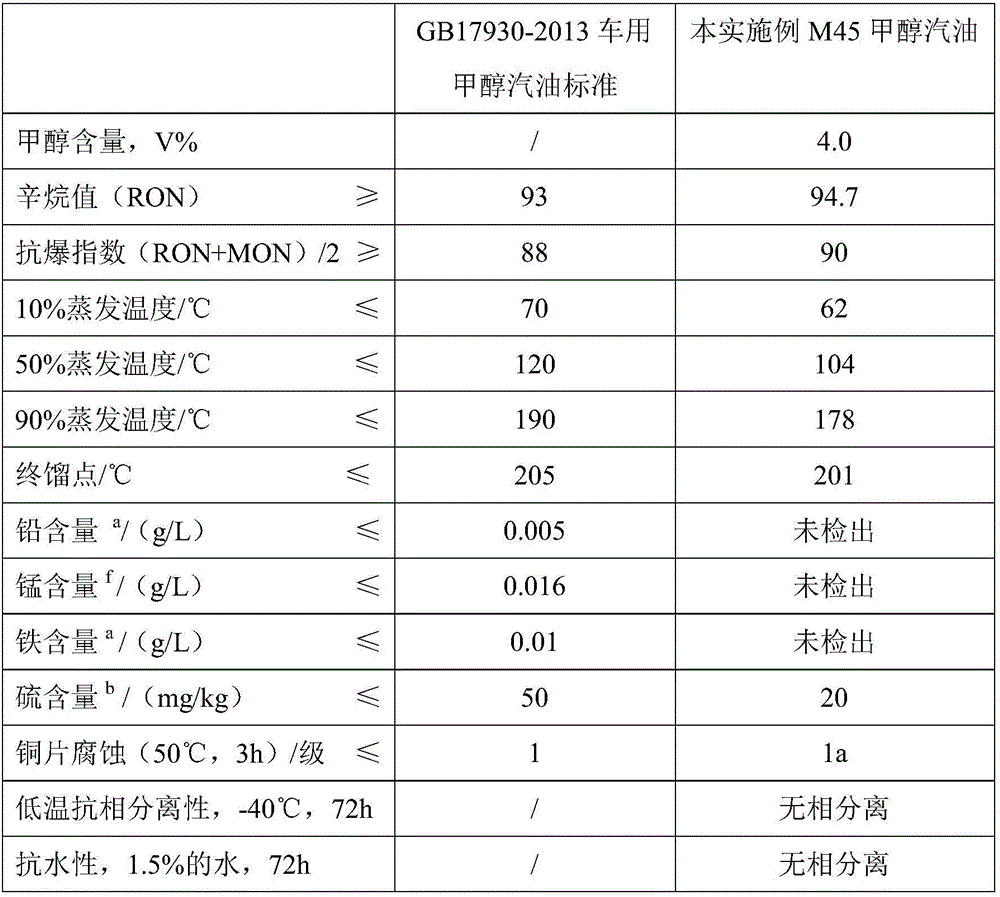

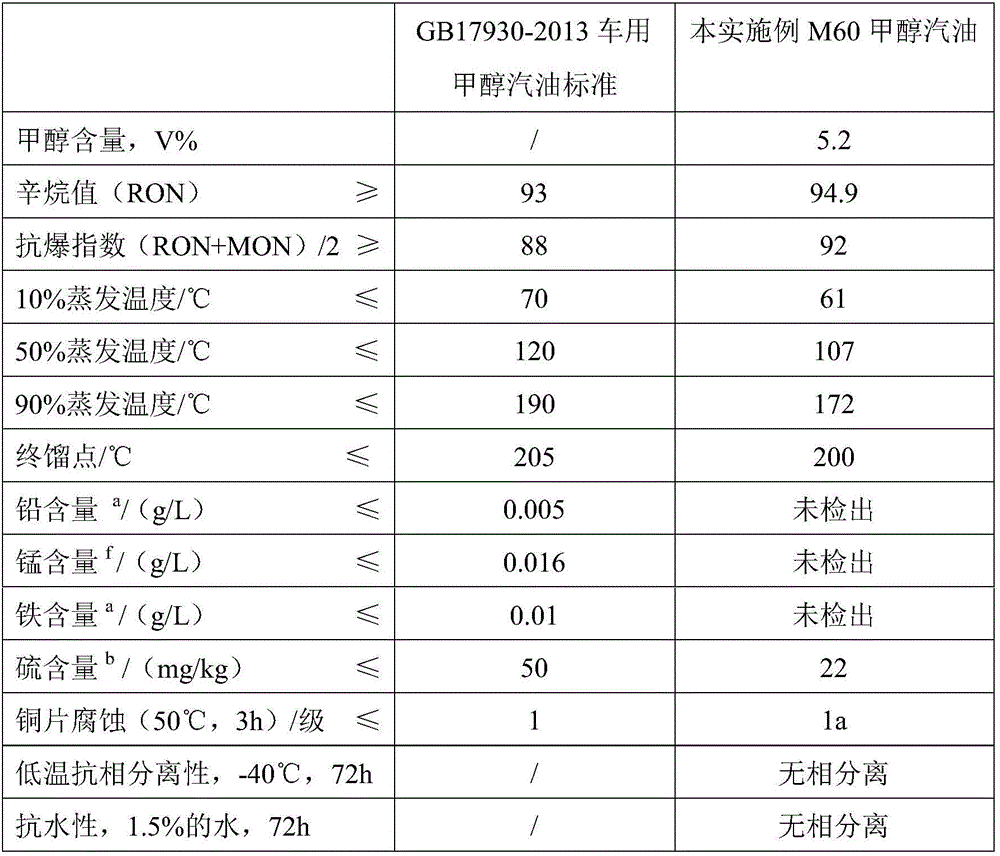

Methanol gasoline composite additive, and preparation method and application thereof

InactiveCN106566584AExtended service lifeBoost octaneLiquid carbonaceous fuelsFuel additivesPotassium hydroxideAlkylbenzenes

The invention relates to a methanol gasoline composite additive, and a preparation method and application thereof. The methanol gasoline composite additive is prepared from the following raw materials in percentage by weight: 68 to 72 percent of animal oil, 0.5 to 1.0 percent of plant oil, 0.2 to 0.5 percent of alkylbenzene, 0.1 to 0.7 percent of monoethanolamine, 0.1 to 0.7 percent of diethanolameine, 0.1 to 0.6 percent of triethanolamine, 1.0 to 2.1 percent of isooctyl nitrate, 1.0 to 2.1 percent of isopropyl nitrate, 1.0 to 2.1 percent of ethyl nitrate, 1.0 to 2.1 percent of sodium hydroxide, 1.0 to 2.1 percent of potassium hydroxide and 18 to 22 percent of water. According to the preparation method, the raw materials are sequentially put into a mixing container according to the proportion, and are stirred at the same time; then, the mixing container is put into ultrasonic waves, and agitation is performed for 15 to 25 min; and the composite additive is obtained. The composite additive provided by the invention can be applied to M25 to M60; the corrosion of methanol gasoline on an automobile can be reduced; and the octane value, the blasting point, the combustion heat value, the oil product quality and the power of the methanol gasoline can be improved.

Owner:XUZHOU LANHAI ENERGY TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com