Storage method of iso-propyl nitrate

A technology of isopropyl nitrate and molecular sieve, applied in the storage field of isopropyl nitrate, can solve the problems of poor storage stability, easy discoloration and the like of isopropyl nitrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

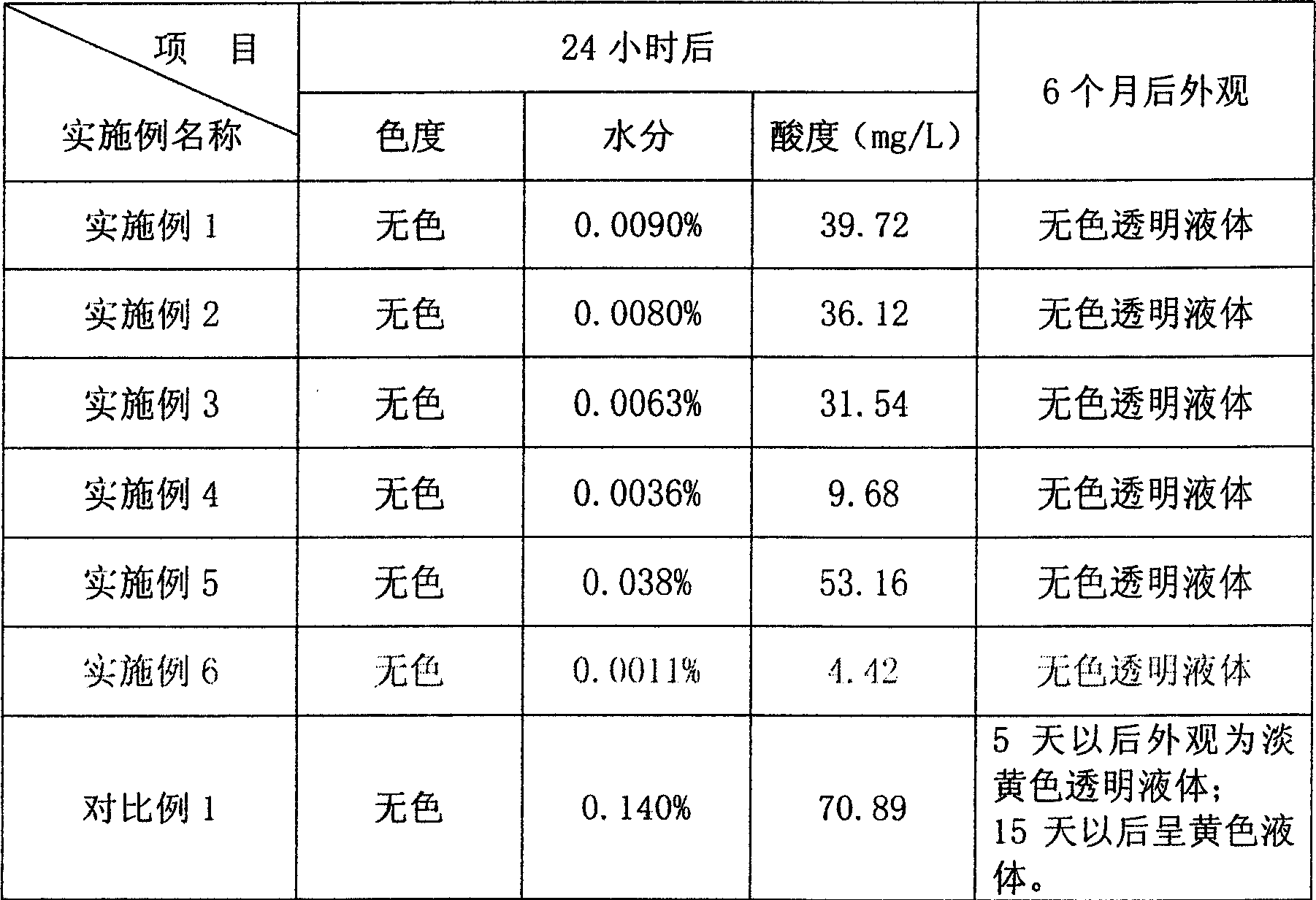

[0013] The industrial product isopropyl nitrate with obvious yellow was dried with anhydrous sodium sulfate for 30 minutes, then distilled, and the colorless main distillate was taken as a sample. The sample is a colorless transparent liquid with a purity of 99.5%, a water content of 0.138%, and an acid value of 69.44 mg / L.

[0014] 4 Å molecular sieves were activated at 500°C for 2 hours, and then placed in a desiccator to cool naturally.

[0015] Get 200 milliliters of isopropyl nitrate samples and add in the Erlenmeyer flask, add 1.0 g of 4 Å molecular sieves, cover the bottle stopper, and seal the bottle stopper with a polyethylene film, and place it in the dark at room temperature. Investigate the appearance, water content and acidity of the sample after 24 hours and the appearance after six months respectively. The test results are shown in Table 1.

Embodiment 2

[0017] 4. Molecular sieve consumption is 2.0 grams, and all the other are the same as implementing 1. The test results are shown in Table 1.

Embodiment 3

[0019] 4. Molecular sieve consumption is 4.0 grams, all the other are with implementing 1. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com