Lab high-temperature aging experiment system for gel state composite fuel

A high-temperature aging and experimental system technology, applied in the field of energetic material performance testing and research, can solve problems such as inability to obtain continuous data, and achieve the effect of large amount of information, not easy to leak, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

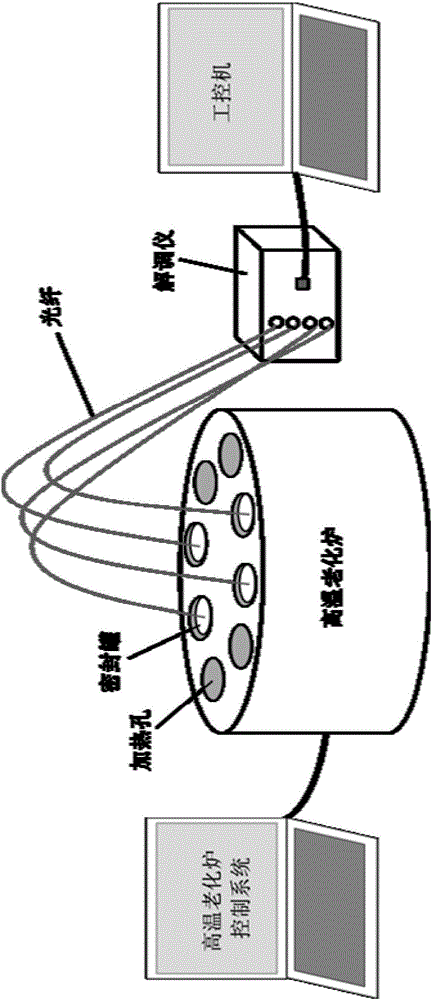

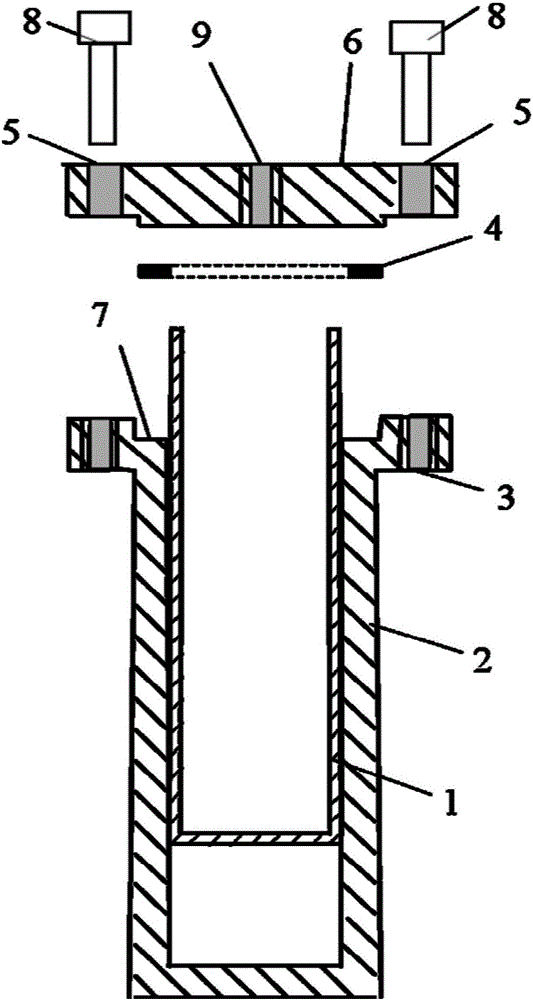

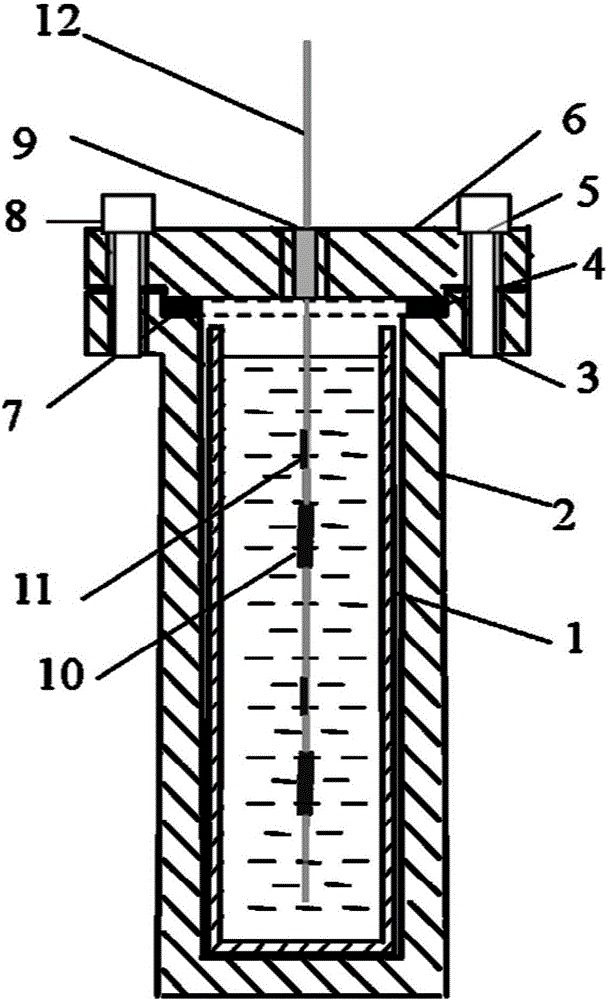

[0042] Such as figure 1 As shown, the laboratory high-temperature aging test system for gel-state cloud explosion agent provided by the present invention includes a sealed tank, an open high-temperature aging system, a fiber grating sensing system, and the like. according to figure 2 , The sealed tank mainly includes components such as a glass reactor 1, a tank body 2, a cover 6, a fixing nut 8, and a sealing ring 4. The tank body 2 is a cylinder with no seal on the top, and an outer fixing ring protruding outwards on the outer ring of the upper end, and 6 through holes 3 for fixing are equidistantly distributed on the outer fixing ring, and the inner edge of the upper end of the tank body is 7 more than the outer edge. The upper end face of the fixed ring is 3mm lower. The glass reactor 1 is an unsealed cylinder whose outer diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com