Catalyst used for production of high-purity terephthalic acid di(2-ethylhexyl) acrylate

A terephthalic acid di-catalyst technology, applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, carboxylate preparation, etc., can solve the problem that the content is difficult to achieve and affects product purity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

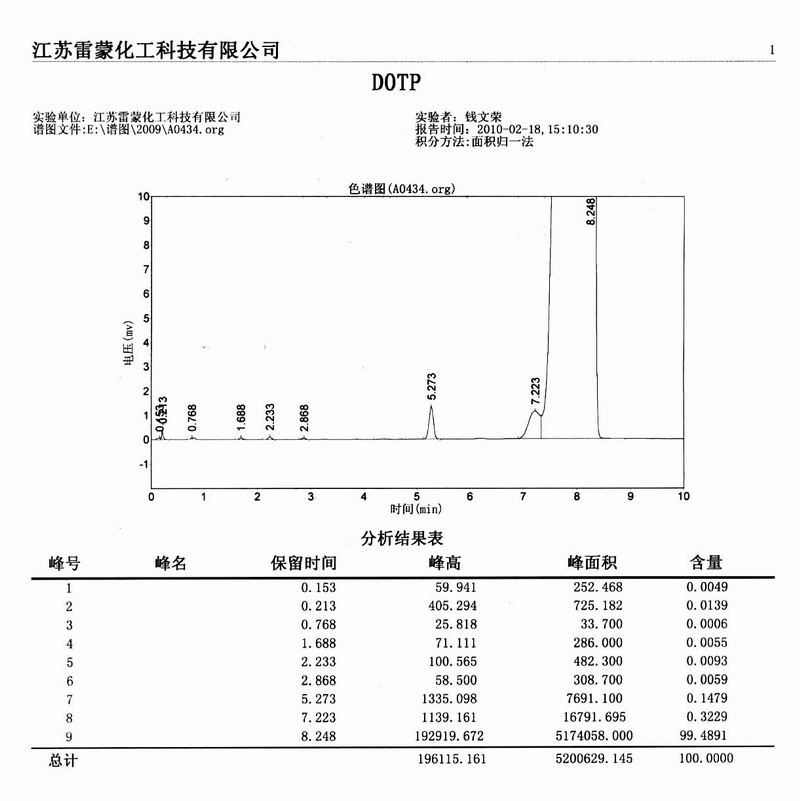

[0026] Example 1 A mixture of 70% tetraisopropyl titanate and 30% tetrabutyl titanate is used as a catalyst (the amount is also 0.43% of PTA, i.e. 3g), the specific operation is:

[0027] Add 700g of PTA, 1650g of octanol, and 2g of active carbon into a 3-liter flask with a stirrer and a distillation device, stir and rapidly heat the mixture in the flask to 170°C, add a mixed catalyst (70% tetraisopropyl titanate and 30% titanium ester tetrabutyl ester mixture) 1.8g for esterification reaction, when the temperature of the mixture in the flask was raised to 205°C, 1.2g of catalyst was added, the esterification time was 6 hours, 153.5ml of reaction water was removed by distillation, and the mixture was The temperature rises to about 225°C, and the acid value of the material is 0.08mgKOH / g, stop heating, cool down to 90°C, add 700ml of 3% NaOH lye (about 40% of the total material), stir for 30min, and stand still for 1 Hours, the lower layer of alkaline water was removed. Add th...

Embodiment 2

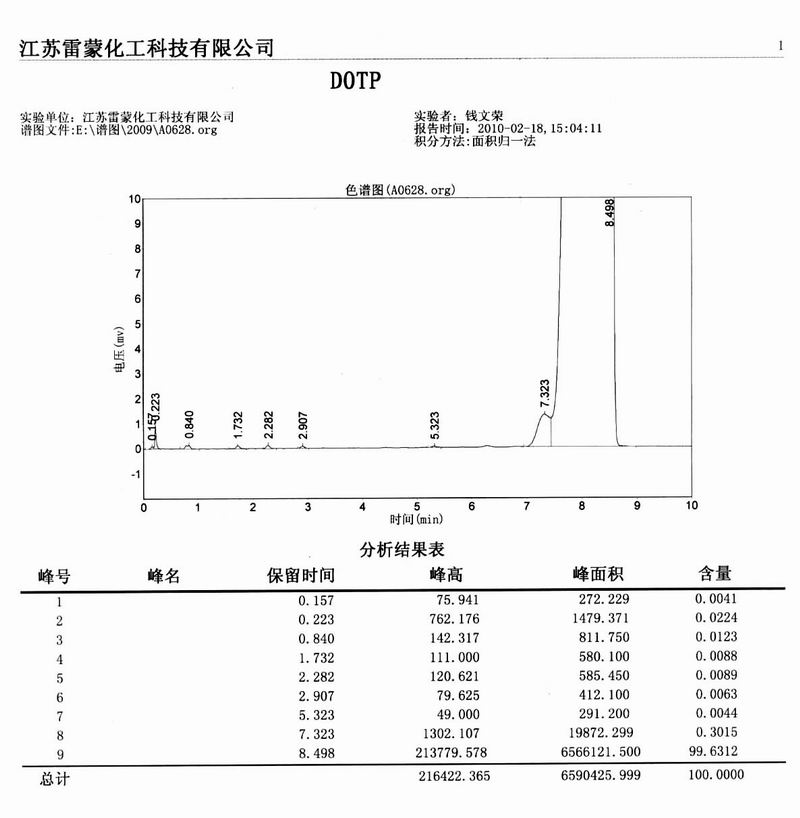

[0029] Example 2 The mixed titanate ester of 75% tetraisopropyl titanate and 25% tetrabutyl titanate was also used as a catalyst, the amount of which was also 0.43% of PTA, i.e. 3g), the specific operation was:

[0030] Add 700g of PTA, 1650g of octanol, and 2g of active carbon into a 3-liter flask with a stirrer and a distillation device, stir and rapidly heat the mixture in the flask to 170°C, add a mixed catalyst (75% tetraisopropyl titanate and 25% mixture of titanium ester tetrabutyl ester) 1.8g for esterification reaction, when the temperature of the mixture in the flask was raised to 205°C, 1.2g of catalyst was added, the esterification time was 6 hours, 153.5ml of reaction water was removed by distillation, and the mixture The temperature of the material rises to about 225°C, and the acid value of the material is 0.08mgKOH / g, stop heating, cool down to reduce the temperature of the material to 90°C, add 700ml of 3% NaOH lye (about 40% of the total material), stir for 30...

Embodiment 3

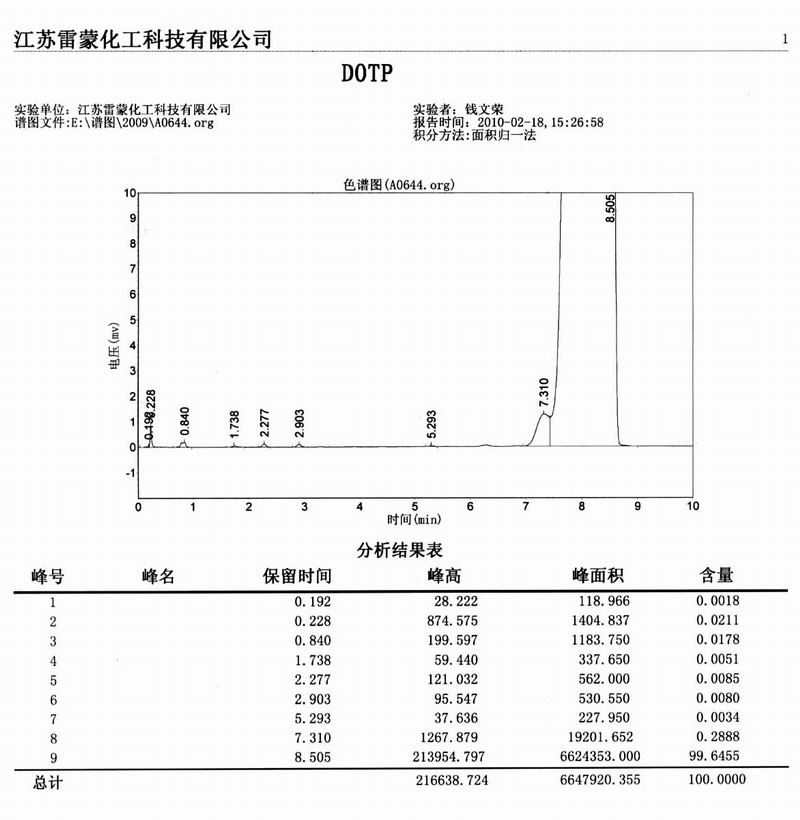

[0033] Embodiment 3 Referring to the manufacturing method of Example 1 or 2, the catalyst used in the process is a combination of tetraisopropyl titanate and tetrabutyl phthalate, and the weight ratio of tetraisopropyl titanate and tetrabutyl phthalate It is 50:50, the amount of catalyst added is 0.2% of the weight of purified terephthalic acid, the temperature of the first addition is 175 ° C, the amount of addition is 60% of the total amount of catalyst, the remaining catalyst is added for the second time, and the temperature The temperature is 203°C, and the purity of the obtained product is 99.5811%.

[0034] The gas chromatographic detection of the product obtained at last refers to the attached Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com