Expansibility characterization method of gel-state solid-liquid high-energy fuel filling explosive body

A high-energy fuel, gel state technology, used in the field of physical and chemical performance testing and research of explosives, can solve the problems of inability to use, high test results, poor mechanical strength of high-energy fuels, etc., to increase structural stability, eliminate potential safety hazards, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

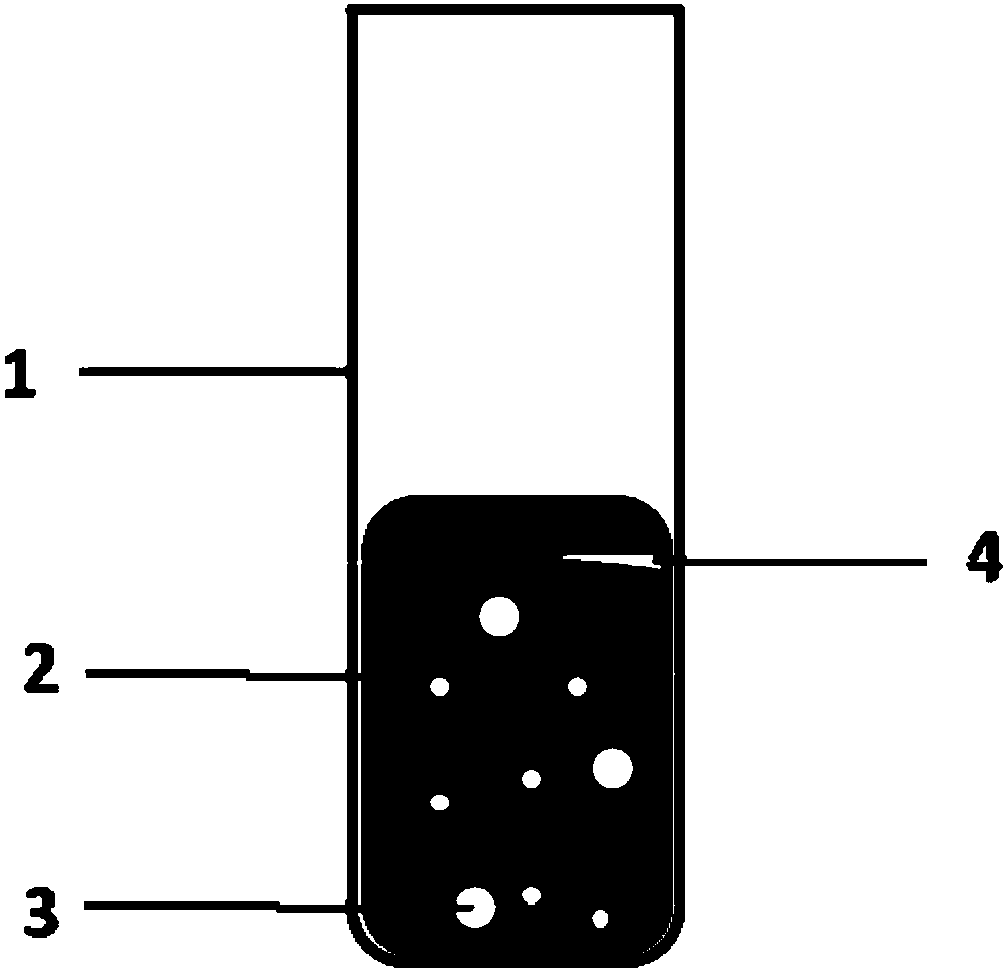

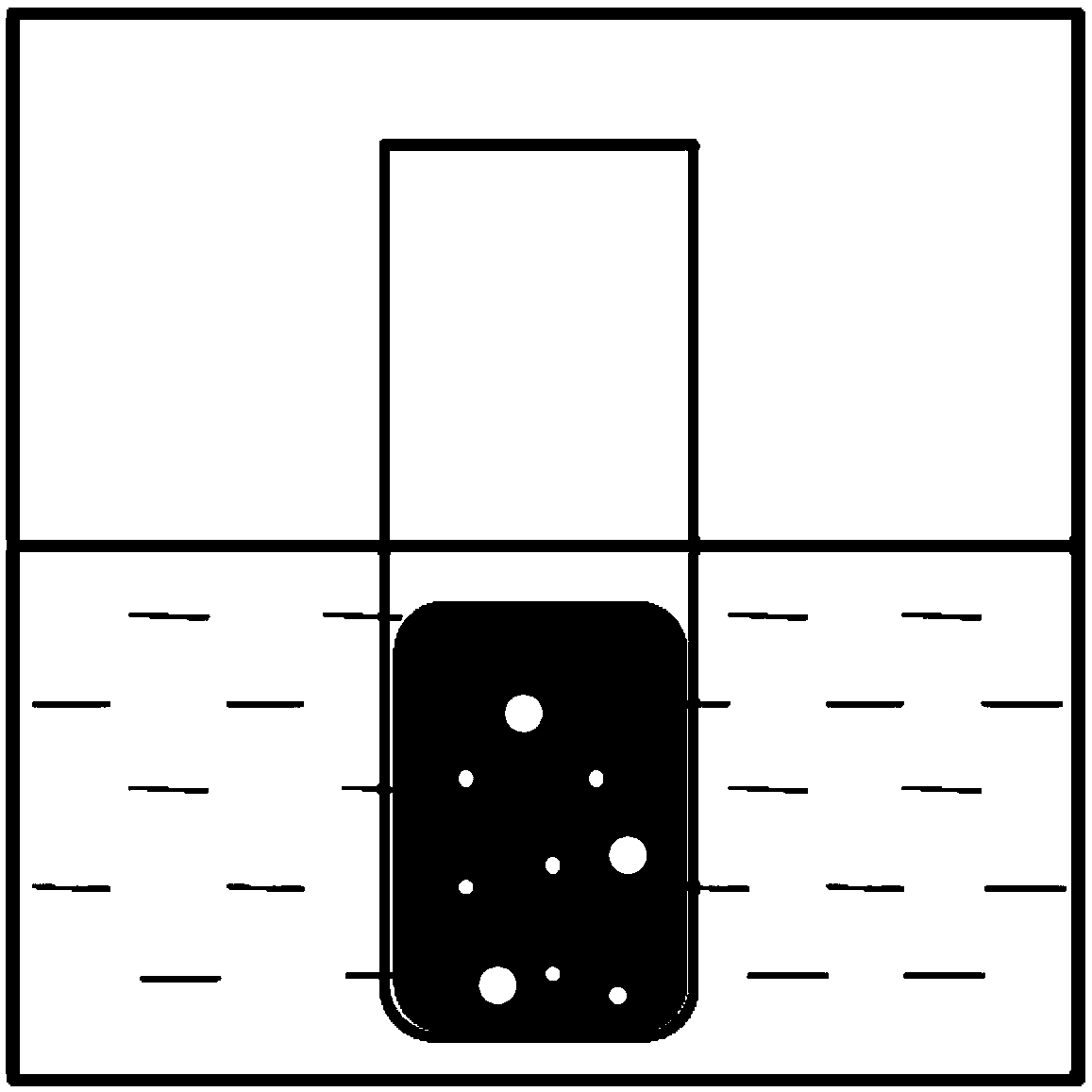

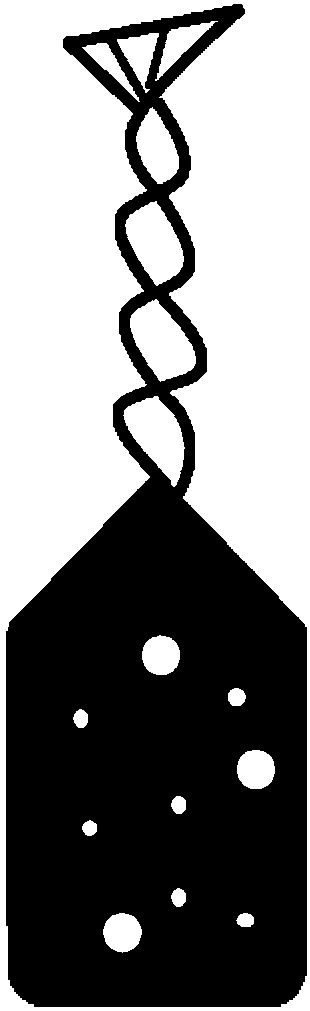

[0036] A gel-state solid-liquid high-energy fuel is composed of fuel hydrocarbon, isopropyl nitrate (sensitizer), aluminum powder and gelling agent. The gelling agent in the sample forms a physically cross-linked spatial network, sealing the fuel hydrocarbon, isopropyl nitrate and aluminum powder in the network space. The sample strength is low, and the volume expansion coefficient cannot be calculated by GJB 770B-2005 method 408.1. Due to the large number of air bubbles in the sample, there are large differences in the volume expansion degree of the sample in the unconfined state, semi-confined state, and constrained state. In order to make the laboratory test results reflect the actual charging situation, the volume expansion in the constrained state should be detected. Coefficient of expansion. The specific research content is described in detail below.

[0037] 1. The bulk expansion coefficient of the sample in an unconstrained state

[0038] Inspired by the liquid volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com