Bonding agent for wax processing of wafer and preparation method thereof

A technology of adhesive and wafer, applied in the directions of wax adhesive, shellac adhesive, rosin adhesive, etc., can solve the problems of inability to meet wafer processing, poor selectivity, low melting point, etc., and improve wafer processing efficiency , easy to store, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

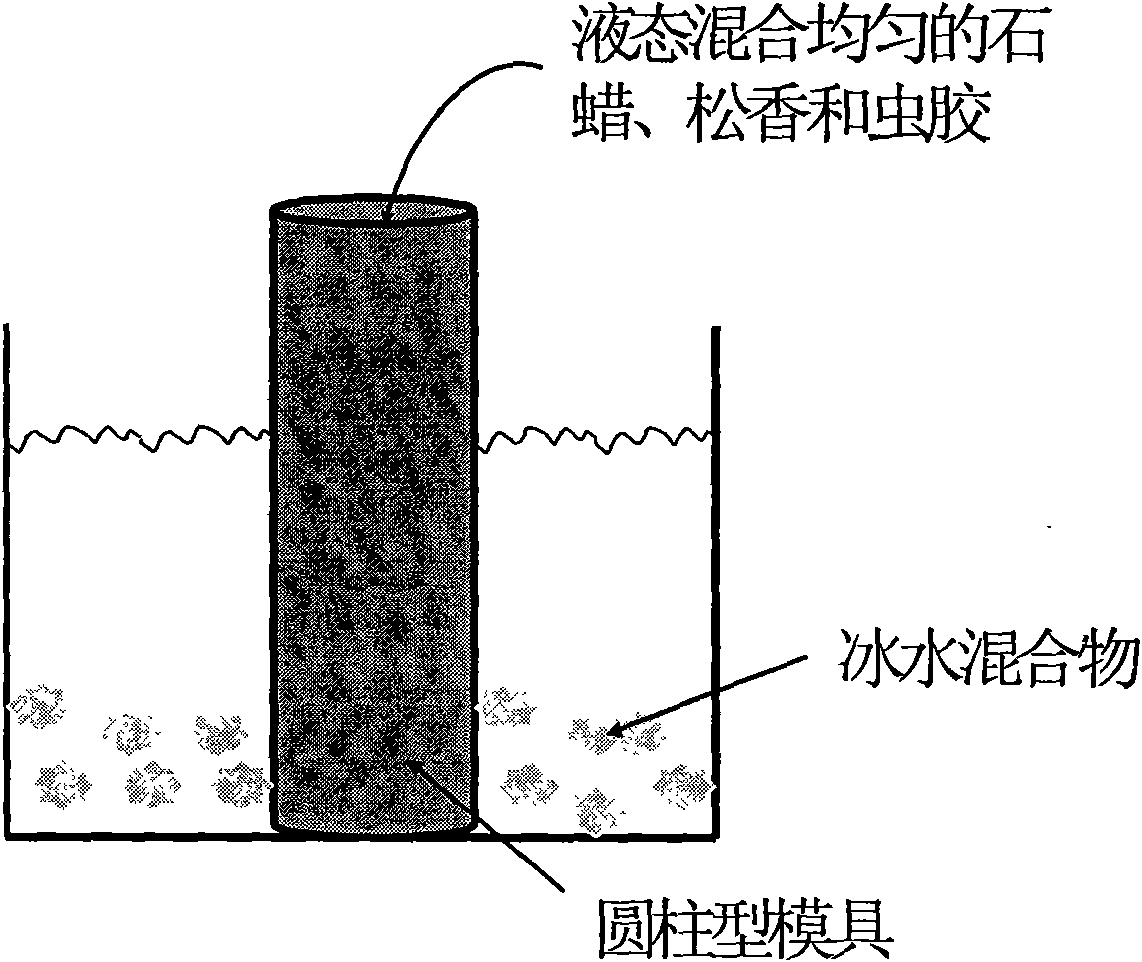

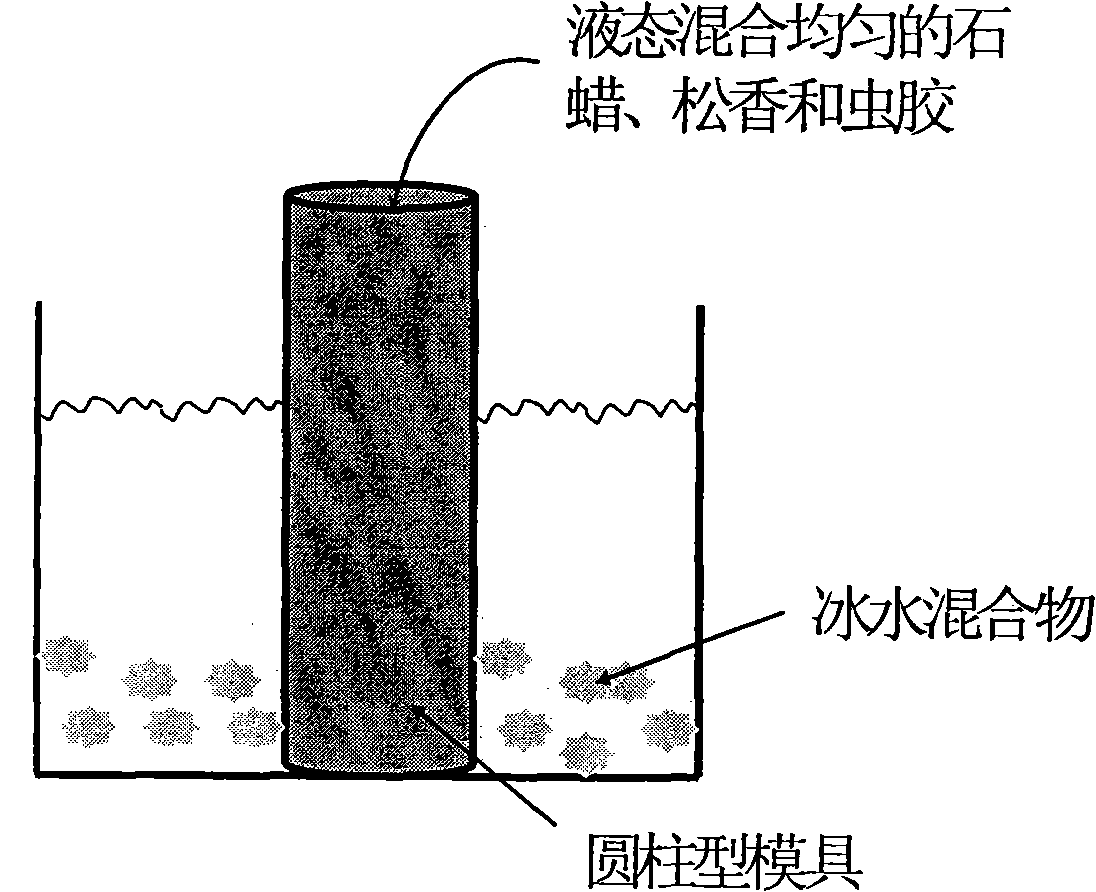

[0021] Paraffin, rosin, and shellac are placed in a heatable container with an electric furnace for heating and melting in a mass ratio of 20:75:5. Heating for 30 minutes, so that the three solids are evenly melted into a liquid state, stirring is required during the melting process, and the mixture is uniform. The uniformly stirred melt is left to stratify, and the upper layer is a transparent liquid after stratification. Fill a large container with deionized water and add a little ice to make an ice-water mixture.

[0022] The mold for preparing the adhesive is cylindrical, and the diameter is selected according to the needs of wafer processing. Put the sealed end of the mold into the ice-water mixture, inject the liquid mixed uniform raw materials into the mold, let it cool and let it solidify (device such as figure 1 shown). The melting point of the prepared binder is between 70°C and 90°C.

Embodiment 2

[0024] Paraffin, rosin, and shellac are placed in a heatable container with an electric furnace for heating and melting in a mass ratio of 50:40:10. Heating for 35 minutes, so that the three solids are uniformly melted into a liquid state, stirring is required during the melting process, and the mixture is uniform. The uniformly stirred melt is left to stratify, and the upper layer is a transparent liquid after stratification. Fill a large container with deionized water and add a little ice to make an ice-water mixture.

[0025] The mold for preparing the adhesive is cylindrical, and the diameter is selected according to the needs of wafer processing. Put the sealed end of the mold into the ice-water mixture, inject the liquid mixed uniform raw materials into the mold, let it cool and let it solidify (device such as figure 1 shown). The melting point of the prepared binder is between 90°C and 110°C.

Embodiment 3

[0027] Paraffin, rosin, and shellac are placed in a heatable container with an electric furnace for heating and melting in a mass ratio of 30:50:20. Heating for 40 minutes, so that the three solids are uniformly melted into a liquid state, stirring is required during the melting process, and the mixture is uniform. The uniformly stirred melt is left to stratify, and the upper layer is a transparent liquid after stratification. Fill a large container with deionized water and add a little ice to make an ice-water mixture.

[0028] The mold for preparing the adhesive is cylindrical, and the diameter is selected according to the needs of wafer processing. Put the sealed end of the mold into the ice-water mixture, inject the liquid mixed uniform raw materials into the mold, let it cool and let it solidify (device such as figure 1 shown). The melting point of the prepared binder is between 110°C and 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com