A special ultra-low hydrogen electrode for welding e911 steel high-pressure steam pipelines and its preparation method

A technology of high-pressure steam and E911, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of uniform melting of the coating, good operability, and increased hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

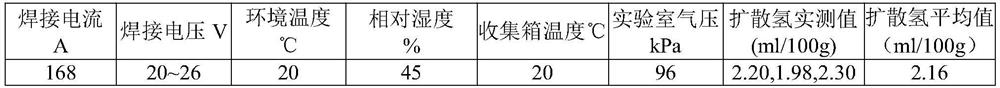

Examples

specific Embodiment approach 1

[0039] Embodiment 1: A special ultra-low hydrogen electrode for welding E911 steel high-pressure steam pipelines in this embodiment is characterized in that the electrode is prepared from a welding core and a coating, and the coating is made of a coating The powder is mixed with potassium sodium water glass, and the coating powder is composed of 20-40 parts of calcite, 2-10 parts of barium carbonate, 17-28 parts of fluorite, 1-8 parts of quartz, and 1 part of rutile in parts by mass. ~7 parts, 0.5~2 parts of soda ash, 1~6 parts of ferrosilicon, 1~5 parts of electrolytic manganese, 0.5~5 parts of metal chromium powder, 0.5~4 parts of medium carbon ferrochromium, 0.5~4 parts of metal molybdenum powder, iron 2 to 15 parts of powder, 0.5 to 2 parts of aluminum-magnesium alloy, 2 to 5 parts of metal tungsten and 0.5 to 3 parts of titanium boron iron; the mass ratio of the coating to the welding core is 1: (2.0 to 5.0) , the mass ratio of the skin powder and potassium sodium water g...

Embodiment 1

[0043]Embodiment 1. A special ultra-low hydrogen electrode for welding E911 steel high-pressure steam pipelines in this embodiment is characterized in that the electrode is prepared from a welding core and a coating, and the coating is made of coating powder Material and potassium sodium water glass are mixed, and described coating powder is made of 36 parts of calcite, 7 parts of barium carbonate, 22 parts of fluorite, 3 parts of quartz, 7 parts of rutile, 0.5 part of soda ash, 45# silicon 3 parts of iron, 4 parts of electrolytic manganese, 1.5 parts of metal chromium powder, 3 parts of medium carbon ferrochrome, 1.3 parts of metal molybdenum powder, 13 parts of iron powder, 2 parts of aluminum-magnesium alloy, 4.4 parts of metal tungsten and 2 parts of ferro-titanium boron made;

[0044] The chemical composition and mass percentage of the welding core are C: 0.07%, Si: 0.1%, Mn: 0.35%, S: 0.002%, P: 0.003%, Cr: 8.0%, Ni: 0.3%, Mo: 0.85%, Nb: 0.06%, V: 0.2%, Cu: 0.03%, Ti: 0...

Embodiment 2

[0058] Embodiment 2, a special ultra-low hydrogen electrode for welding E911 steel high-pressure steam pipelines according to this embodiment is characterized in that the electrode is prepared from a welding core and a coating, and the coating is made of coating powder Material and potassium sodium water glass are mixed, and described coating powder is made of 38 parts of calcite, 5 parts of barium carbonate, 24 parts of fluorite, 4 parts of quartz, 6 parts of rutile, 1 part of soda ash, 45# silicon 3.2 parts of iron, 3.5 parts of electrolytic manganese, 1.8 parts of metal chromium powder, 2.8 parts of medium-carbon ferrochrome, 1 part of metal molybdenum powder, 10 parts of iron powder, 1.5 parts of aluminum-magnesium alloy, 4.8 parts of metal tungsten and 1 part of ferro-titanium boron made;

[0059] The chemical composition and mass percentage of the welding core are C: 0.07%, Si: 0.1%, Mn: 0.35%, S: 0.002%, P: 0.003%, Cr: 8.0%, Ni: 0.3%, Mo: 0.85%, Nb: 0.06%, V: 0.2%, Cu:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com