A kind of ternary copolymerization high temperature resistant nylon and preparation method thereof

A high temperature resistant nylon technology, applied in the field of ternary copolymerization high temperature resistant nylon and its preparation, can solve the problems of less development of high temperature resistant nylon, low monomer activity, complex synthesis route, etc. A variety of effects with a simple synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

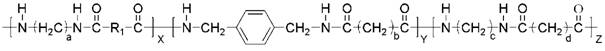

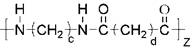

[0092] 1mol of 2,4-bisphenyl symmetric triazine-N-carboxyphenylphthalimide dibasic acid and 1mol or (116g) hexamethylenediamine are salted in water to obtain component A;

[0093] 1mol p-xylylenediamine and 1mol or adipic acid are salified in water to obtain component B;

[0094] Component A, B and nylon 66 salt mass are respectively 3kg, 5kg and 2kg into the reactor, and add 50g sodium hypophosphite and 500g deionized water, replace the air in the reactor with high-purity nitrogen 4 times, be warming up to 200 ℃, keep the pressure in the kettle at 2.5MPa;

[0095] Continue to heat up to 300°C, keep the pressure in the kettle at 2.0MPa, hold the pressure for 2h, release the air to normal pressure, drain the water in the system, and then gradually evacuate the system to depressurize the system to -0.05MPa, and discharge the material to obtain a ternary Copolymerized high temperature nylon.

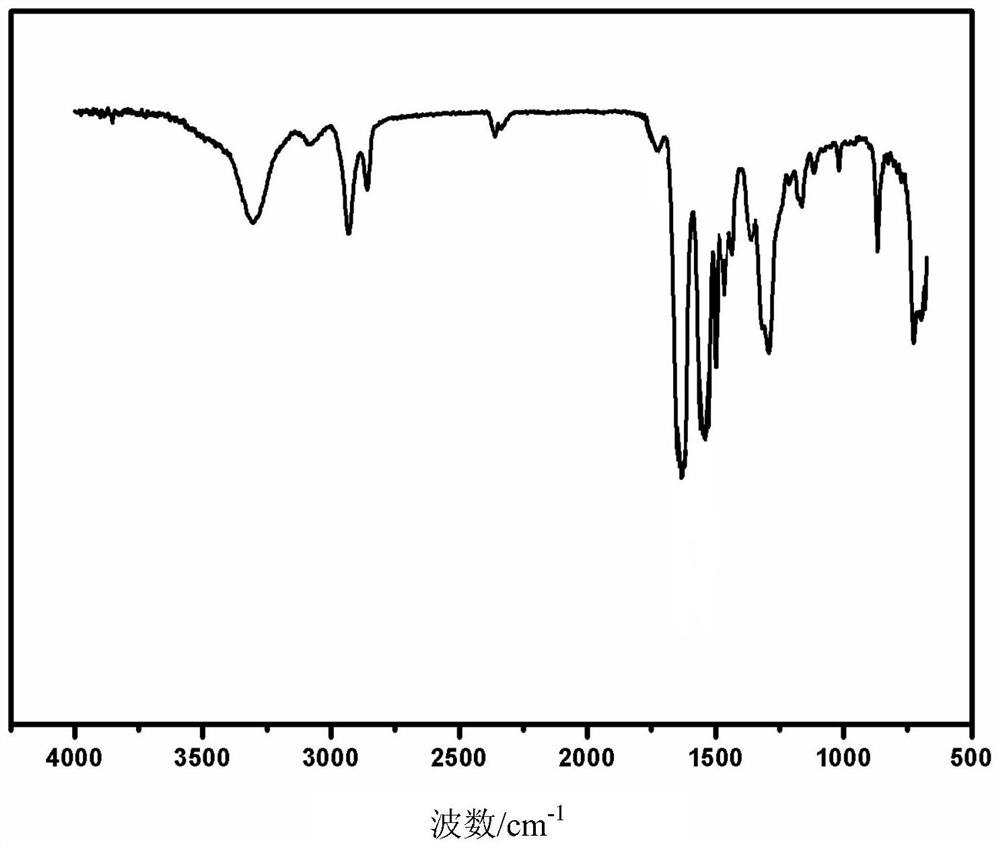

[0096] Infrared test is carried out on the obtained final product ternary copolymeriz...

Embodiment 2

[0098] 1mol of 3,3',4,4'-p-terphenyl-N-carboxyphenylphthalimide and 1mol of hexamethylenediamine are salted in water to obtain component A;

[0099] 1mol of p-xylylenediamine and 1mol of adipic acid are salified in water to obtain component B;

[0100] Component A, B and nylon 66 salt are respectively 3kg, 5kg and 2kg into the reactor according to the mass, and an appropriate amount of sodium hypophosphite and deionized water are added, and the air in the reactor is replaced with high-purity nitrogen 4 times, and the temperature is increased to 200℃, keep the pressure in the kettle at 2.5MPa;

[0101] Continue to heat up to 320 °C, keep the pressure in the kettle at 2.0 MPa, after maintaining the pressure for 2 hours, release the air to normal pressure, discharge the water in the system, and then gradually vacuumize the system to depressurize the system to -0.05 MPa, and discharge the material to obtain a ternary Copolymerized high temperature nylon. The relative viscosity o...

Embodiment 3

[0103] 1mol of 3,3',4,4'-m-terphenyl-N-carboxyphenylphthalimide and 1mol of hexamethylenediamine are salted in water to obtain component A;

[0104] 1mol of p-xylylenediamine and 1mol of adipic acid are salified in water to obtain component B;

[0105] Component A, B and nylon 66 salt are respectively 3kg, 5kg and 2kg into the reactor according to the mass, and an appropriate amount of sodium hypophosphite and deionized water are added, and the air in the reactor is replaced with high-purity nitrogen 4 times, and the temperature is increased to 200 °C, keep the pressure in the kettle at 2.5MPa, continue to heat up to 320 °C, keep the pressure in the kettle at 2.0MPa, after maintaining the pressure for 2 hours, vent to normal pressure, drain the water in the system, and then gradually vacuumize the system to reduce the pressure to -0.04MPa, the ternary copolymerization high temperature resistant nylon is obtained after discharging. The relative viscosity of the obtained terpol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com