Flaxseed oil microcapsule and production method thereof

A linseed oil and microcapsule technology, which is applied in the directions of edible oil/fat, food forming, food science, etc., can solve the problems of difficulty in guaranteeing the shelf life of linseed oil products, affecting product safety and quality, reducing nutritional value, etc. Conducive to industrialization and large-scale production, good taste and flavor, long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Add 80g of maltodextrin, 70g of modified starch and 50g of sodium caseinate into 600g of hot water at 50°C, and stir at high speed to completely dissolve them to form an aqueous phase;

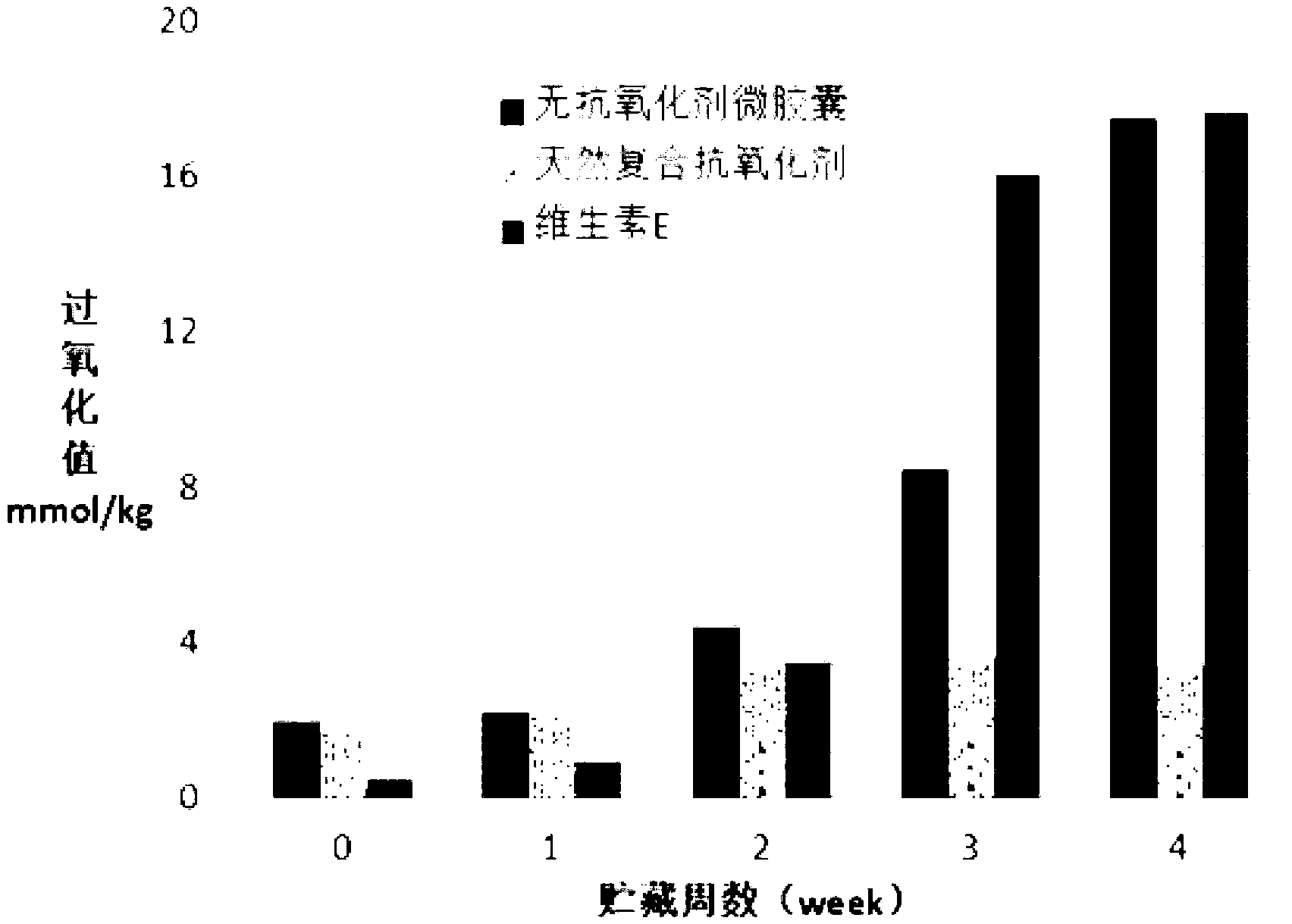

[0038] 2) Weigh 50g of linseed oil, gradually add vitamin E to 200ppm, rosemary to 50ppm and tea polyphenols to 50ppm and stir to dissolve completely to form an oil phase;

[0039] 3) Use a shear to shear the water phase obtained in step 1) at 10,000 rpm at high speed, and slowly add the oil phase obtained in step 2). After the oil phase is completely added, keep shearing for 10 minutes to obtain an emulsion.

[0040] 4) Use a high-pressure homogenizer to homogenize the emulsion obtained in the above step 3) at 30-50°C for 3 times, and the homogenization pressure is 20MPa.

[0041]5) Use an ultra-high temperature instant sterilizer to sterilize the homogenized emulsion obtained in step 4) at 110°C for 15s;

[0042] 6) Spray-dry the sterilized emulsion obtained in step 5), the air in...

Embodiment 2

[0047] 1) Weigh 100g of maltodextrin, 50g of modified starch and 50g of sodium caseinate into 800g of hot water at 60°C, stir at high speed to dissolve them completely, and form an aqueous phase;

[0048] 2) Weigh 100g of linseed oil, gradually add vitamin E to 100ppm, rosemary to 200ppm and tea polyphenols to 100ppm and stir to dissolve completely to form an oil phase;

[0049] 3) Use a shearer to shear the water phase obtained in step 1) at 15,000 rpm at high speed, and slowly add the oil phase obtained in step 2). After the oil phase is completely added, keep shearing for 15 minutes to obtain an emulsion.

[0050] 4) Use a high-pressure homogenizer to homogenize the emulsion obtained in the above step 3) at 30-50°C for 3 times, and the homogenization pressure is 20MPa.

[0051] 5) Use an ultra-high temperature instant sterilizer to sterilize the homogenized emulsion obtained in step 4) at 115°C for 10s;

[0052] 6) Spray-dry the sterilized emulsion obtained in step 5), the...

Embodiment 3

[0054] 1) Add 50g of maltodextrin, 50g of modified starch and 50g of sodium caseinate into 450g of hot water at 45°C, and stir at high speed to completely dissolve them to form a water phase;

[0055] 2) Weigh 150g of linseed oil, gradually add vitamin E to 50ppm, rosemary to 200ppm and tea polyphenols to 50ppm and stir to completely dissolve to form an oil phase;

[0056] 3) Use a shear to shear the water phase obtained in step 1) at 20,000 rpm at high speed, and slowly add the oil phase obtained in step 2). After the oil phase is completely added, keep shearing for 15 minutes to obtain an emulsion.

[0057] 4) Use a high-pressure homogenizer to homogenize the emulsion obtained in the above step 3) at 30-50°C for 3 times, and the homogenization pressure is 20MPa.

[0058] 5) Use an ultra-high temperature instant sterilizer to sterilize the homogenized emulsion obtained in step 4) at 110°C for 10s;

[0059] 6) Spray-dry the sterilized emulsion obtained in step 5), the air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com