Pure walnut skim powder and manufacturing method and application thereof

A technology for walnuts and walnut meal, which is applied in the field of walnut defatted whole powder and its preparation, which can solve the problems of inappropriate addition of flavor and color, product browning, and bitterness to the walnut defatted whole powder, so as to avoid difficult storage and reduce quality deterioration Poor, nutritional and safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

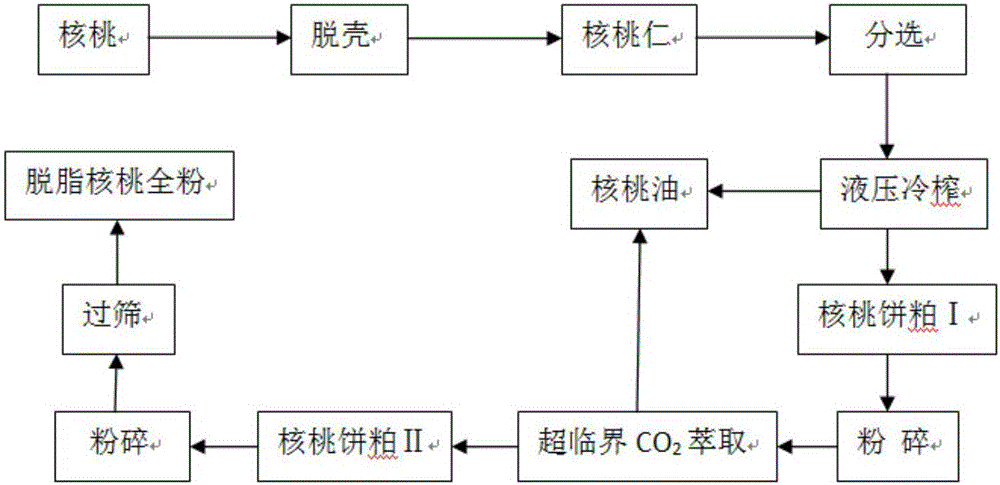

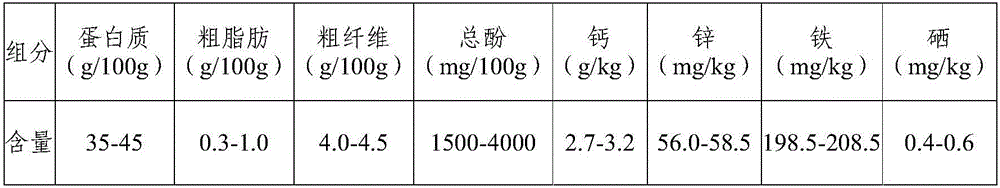

Method used

Image

Examples

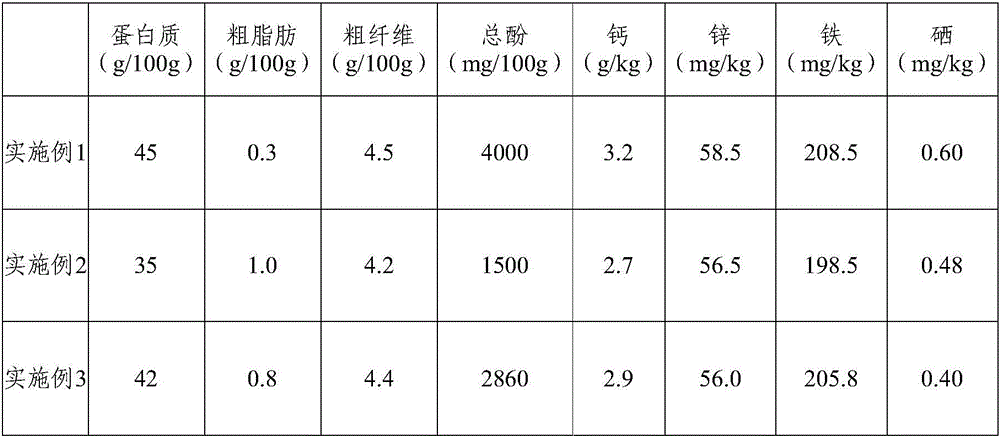

Embodiment 1

[0047] Embodiment 1 Degreased whole walnut powder and preparation method thereof

[0048] 1. Sorting of walnut kernels: After shelling walnuts and extracting kernels, select walnut kernels without mildew and with seed coats, and remove broken walnut shells and other impurities.

[0049] 2. Hydraulic oil press pressing: the raw material used is 30kg, the temperature of the pressing chamber is controlled at 50°C, and then the following operations are performed: ①The pressure rises to 20Mpa and maintains for 15min, ②Then the pressure drops to 0Mpa, and then the pressure rises to 30Mpa , maintain for 20 minutes, repeat ①~②, can squeeze for many times, and the residual oil in walnut meal Ⅰ can reach 10%.

[0050] 3. Crushing of the walnut cake I: use a crusher to break the walnut cake I into powders with a particle size below 0.3cm.

[0051] 4. Supercritical CO 2 Extraction: Weigh 15kg of walnut meal I powder, put it into the barrel and put it into the extraction kettle, turn on ...

Embodiment 2

[0053] Embodiment 2 Degreased whole walnut powder and preparation method thereof

[0054] 1. Sorting of walnut kernels: After shelling walnuts and extracting kernels, select walnut kernels without mildew and with seed coats, and remove broken walnut shells and other impurities.

[0055] 2. Pressing by hydraulic oil press: The raw material used is 1kg, the temperature of the press chamber is controlled at 30°C, and then the following operations are performed: ①The pressure rises to 5Mpa and maintains for 5min, ②Then reduce the pressure to 0Mpa, and then raise the pressure to 20Mpa , maintain for 5 minutes, repeat ①~②, can squeeze for many times, the residual oil in walnut meal Ⅰ reaches 20%.

[0056] 3. Crushing of the walnut cake I: use a crusher to break the walnut cake I into powders with a particle size below 0.3cm.

[0057] 4. Supercritical CO 2 Extraction: Weigh 1kg of walnut meal I powder, put it into the barrel and put it into the extraction kettle, turn on the refrig...

Embodiment 3

[0059] Embodiment 3 walnut defatted whole powder and preparation method thereof

[0060] 1. Sorting of walnut kernels: After shelling walnuts and extracting kernels, select walnut kernels without mildew and with seed coats, and remove broken walnut shells and other impurities.

[0061] 2. Hydraulic oil press pressing: the raw material used is 50kg, the temperature inside the oil press is controlled at 60°C, and then the following operations are carried out: ①The pressure rises to 30Mpa and maintains for 20min, ②Then reduce the pressure to 0Mpa, and then reduce the pressure Raise to 40Mpa, maintain for 30 minutes, repeat ①~②, can squeeze for many times, and the residual oil in walnut meal Ⅰ reaches 15%.

[0062] 3. Crushing of the walnut cake I: use a crusher to break the walnut cake I into powders with a particle size below 0.3cm.

[0063] 4. Supercritical CO 2 Extraction: Weigh 20kg of walnut meal I powder, put it into the barrel and put it into the extraction kettle, turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com