Beta-carotene micro-capsule powder and preparation method thereof

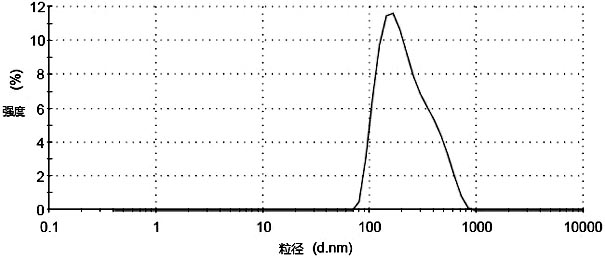

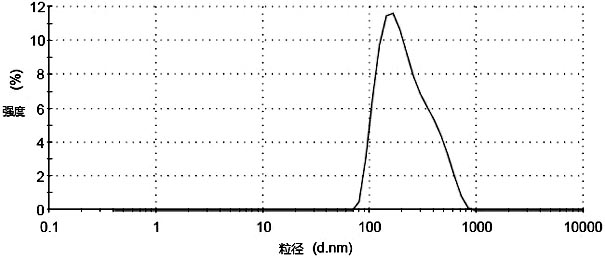

A carotene and microcapsule powder technology is applied in food preparation, chemical instruments and methods, azo dyes, etc., and can solve the problems of poor dispersibility, long time required for dissolution of beta-carotene microcapsule powder, poor stability, and the like, Achieve the effects of good stability, easy continuous and automated production, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Select 200g of fresh carrots, wash them with clean water, drain and pulverize them, then dry them in an oven at 40°C for 2 hours, then pulverize the dried carrots with a pulverizer and pass through an 8-mesh sieve.

[0050]Put the quantitative dry raw materials into a 1000 mL flask, add 400 mL of vegetable oil-edible alcohol mixed extract with a volume ratio of 3:7 for extraction, the extraction reagent is food grade, and an ultrasonic extraction device is used, and the extraction temperature is 45 °C. The ultrasonic extraction frequency is 2500MHz, the extraction time is 90min, and then the extract is filtered to remove solid matter. Concentrate the filtrate with a rotary evaporator, recover the solvent, and then dry it in a vacuum freeze dryer to obtain a β-carotene extract.

[0051] Add 5.0% of β-carotene, 5.0% of soybean lecithin and 5.0% of vitamin C palmitate into the organic phase with edible alcohol as the solvent, the concentration of the organic phase solution...

Embodiment 2

[0054] Select 200g of fresh carrots, wash them with clean water, drain them, and crush them, then dry them in an oven at 40°C for 2.5 hours, then crush them with a grinder and pass them through an 8-mesh sieve.

[0055] Put the quantitative dry raw materials into a 1000 mL flask, add 300 mL vegetable oil-edible alcohol volume ratio of 5:5 mixed extraction solution, the extraction reagent is food grade, use an ultrasonic extraction device, the extraction temperature is 35 ° C, ultrasonic The extraction frequency was 1500MHz, the extraction time was 120 min, and then the extract was filtered to remove solid matter. Concentrate the filtrate with a rotary evaporator, recover the solvent, and then dry it in a vacuum freeze dryer to obtain a β-carotene extract.

[0056] Add 4.0% of β-carotene, 3.0% of soybean lecithin and 3.0% of vitamin C palmitate into the organic phase of edible alcohol and vegetable oil 1:1 as the solvent, the concentration of the organic phase solution is 25%; ...

Embodiment 3

[0059] Select 250g of fresh carrots, wash them with clean water, drain them, and crush them, then dry them in an oven at 40°C for 2.5 hours, then crush them with a grinder and pass them through an 8-mesh sieve.

[0060] Put the quantitative dry raw materials into a 1000 mL flask, add 500 mL of vegetable oil-edible alcohol mixed extract solution with a volume ratio of 4:6 for extraction, the extraction reagent is food grade, use an ultrasonic extraction device, the extraction temperature is 50 ° C, ultrasonic The extraction frequency was 3000MHz, the extraction time was 60 min, and then the extract was filtered to remove solid matter. Concentrate the filtrate with a rotary evaporator, recover the solvent, and then dry it in a vacuum freeze dryer to obtain a β-carotene extract.

[0061] Add 6% of β-carotene, 2.5% of soybean lecithin and 3.5% of vitamin C palmitate into the organic phase with edible vegetable oil as the solvent, the concentration of the organic phase solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com