Method for demulsification for extracting wheatgerm oil by using aqueous enzymatic method

A technology of wheat germ oil and wheat germ, which is applied in the direction of fat oil/fat production, fat production, etc., to achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

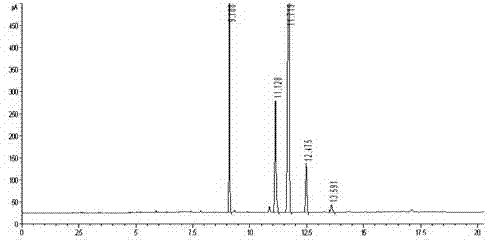

Image

Examples

Embodiment 1

[0041] The method for demulsification in extracting wheat germ oil by aqueous enzymatic method comprises the following steps:

[0042] Raw material pretreatment: take the raw material wheat germ, dry it at 105°C for 15 minutes, and cool it to room temperature for later use;

[0043] Superfine pulverization: Superfine pulverization of the dried and cooled wheat germ to 800 meshes;

[0044] Compound enzymatic hydrolysis and oil extraction: Take the crushed raw material wheat germ, add water at a ratio of 1:6 between material and water, and then add a compound enzyme of cellulase and protease for enzymolysis. The protease is acid protease, cellulose The weight ratio of enzyme to acid protease is 1:5, and the amount of compound enzyme accounts for 2.27% of the weight of wheat germ; the enzymolysis conditions are: pH5, enzymolysis temperature 50°C, enzymolysis time 6h;

[0045] Centrifugal separation: After enzymatic hydrolysis, centrifuge at a speed of 4000-4500r / min for 15-20min...

Embodiment 2

[0057] The method for demulsification in extracting wheat germ oil by aqueous enzymatic method comprises the following steps:

[0058] Raw material pretreatment: take the raw material wheat germ, dry it at 100-105°C for 15-20min, and cool it to room temperature for later use;

[0059] Superfine pulverization: superfine pulverization of dried and cooled wheat germ to 800-1000 mesh;

[0060] Compound enzymatic hydrolysis and oil extraction: take the crushed raw material wheat germ, add water at a ratio of 1:6 between material and water, and then add a compound enzyme of cellulase and protease for enzymolysis. The protease is papain, cellulose The weight ratio of enzyme to papain is 1:5, and the amount of compound enzyme accounts for 2.27% of the weight of wheat germ; the enzymolysis conditions are: pH6, enzymolysis temperature 60°C, enzymolysis time 5h;

[0061] Centrifugal separation: After enzymatic hydrolysis, centrifuge at a speed of 4000-4500r / min for 15-20min: after centr...

Embodiment 3

[0069] The method for demulsification in extracting wheat germ oil by aqueous enzymatic method comprises the following steps:

[0070] Raw material pretreatment: take the raw material wheat germ, dry it at 100-105°C for 15-20min, and cool it to room temperature for later use;

[0071] Superfine pulverization: superfine pulverization of dried and cooled wheat germ to 800-1000 mesh;

[0072] Compound enzymatic hydrolysis and oil extraction: Take the crushed raw material wheat germ, add water according to the ratio of 1:6 between material and water, and then add a compound enzyme of cellulase and protease for enzymolysis. The protease is neutral protease, fiber The weight ratio of suzyme and neutral protease is 1:5, and the amount of compound enzyme accounts for 2.27% of the weight of wheat germ; the enzymolysis conditions are: pH7, enzymolysis temperature 55°C, enzymolysis time 6h;

[0073] Centrifugal separation: After enzymatic hydrolysis, centrifuge at a speed of 4000-4500r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com