Method for preparing zirconium by TBP extraction method

A technology of extraction and zirconia, applied in the field of hydrometallurgy, which can solve the problems of emulsification and high silicon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

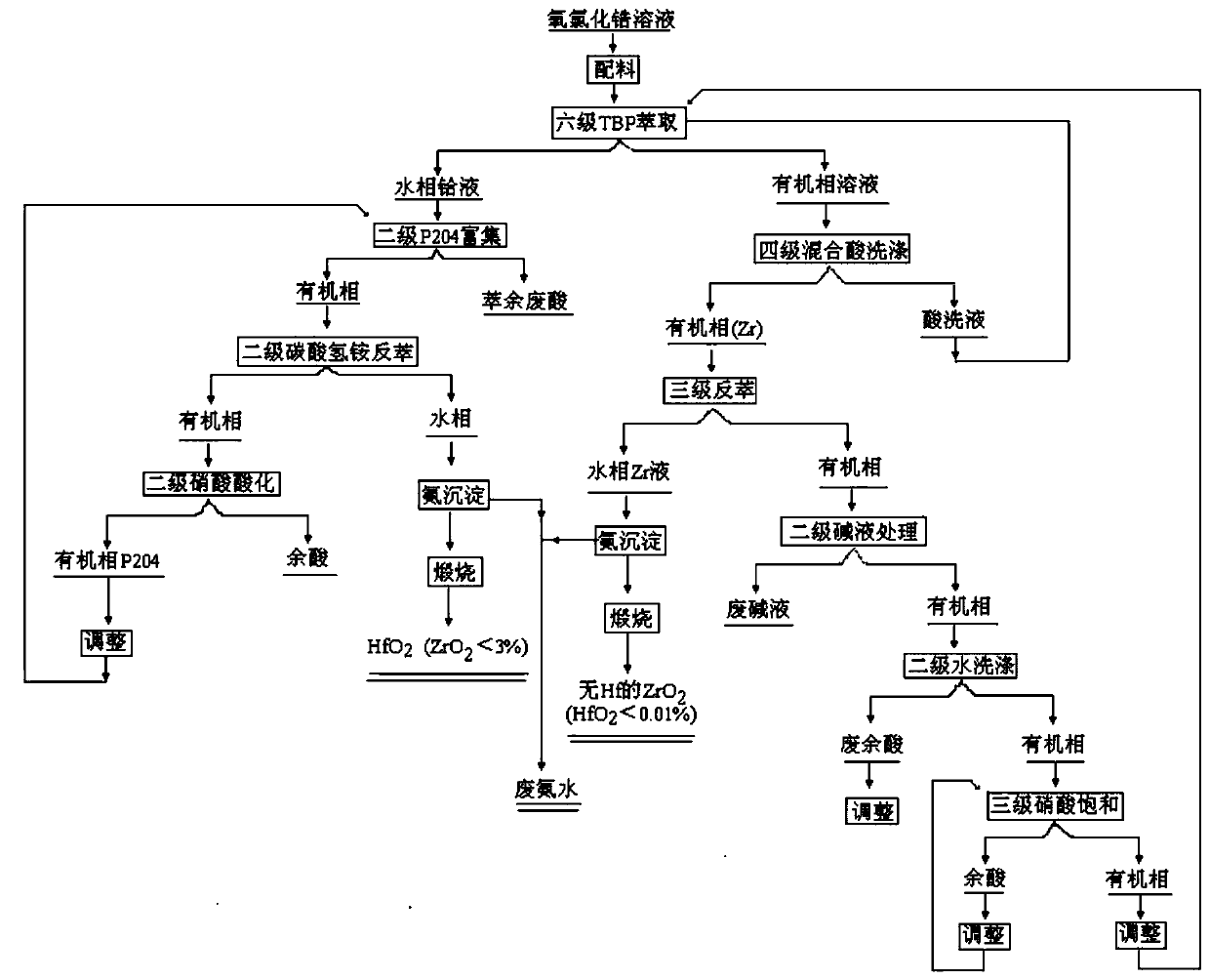

[0032] Embodiment 1: technological process

[0033] Step 1: After adding ingredients into the zirconium oxychloride solution, carry out six-stage TBP extraction. The ingredients are a mixture of hydrochloric acid and nitric acid. The TBP organic phase used for extraction is made of 60% tributyl phosphate and 40% kerosene to obtain water Phase hafnium liquid and organic phase solution.

[0034] Step 2: the aqueous phase hafnium liquid obtained in step 1 is enriched and extracted with secondary diisooctyl phosphate (P204) to obtain an organic phase and raffinate waste acid, and the P204 organic phase is composed of 10% diisooctyl phosphate, 85% kerosene and 5% tributyl phosphate made.

[0035] Step 3: The organic phase obtained in step 2 is subjected to secondary ammonium bicarbonate back extraction to obtain an organic phase and an aqueous phase.

[0036] Step 4: The organic phase obtained in step 3 is acidified with secondary nitric acid to obtain an organic phase of diisooc...

Embodiment 2

[0044] Embodiment 2: operation process

[0045] The control and operating method of the equipment designed according to the technological process of embodiment 1 are as follows:

[0046] (1) Connection of the extraction tank: The extraction tank must first be cleaned and connected. Check that the switches (valves), flow meters, and pipelines of each inlet and outlet are smooth and normal. Check that upstream and downstream device settings are in place.

[0047] (2) Filling: according to the technical conditions - the ratio and the series are filled with each solution, and the empty tank does not move.

[0048] (3) Turn on the mixer, and measure the static and dynamic liquid level height difference of each extraction tank.

[0049] (4) Carry out normal operation according to the determined flow rate.

[0050] (5) Determination of acidity and ZrO in extraction grade 2 content.

[0051] (6) When the operation reaches equilibrium, directly determine whether the Hf liquid wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com