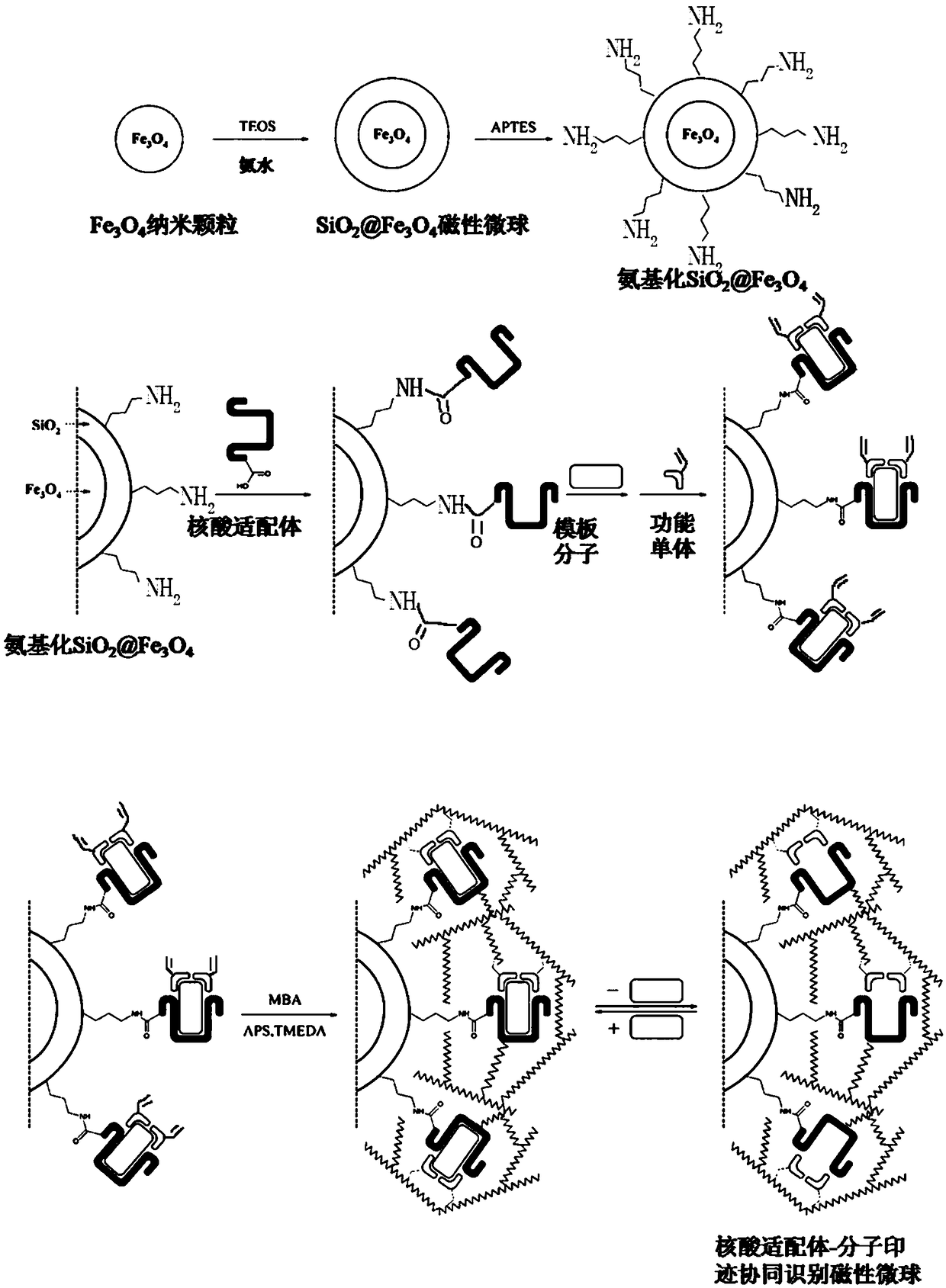

Nucleic acid aptamer-molecular imprinting synergistic recognition magnetic microspheres and preparation method and application thereof

A nucleic acid aptamer, magnetic microsphere technology, applied in chemical instruments and methods, material separation, analysis of materials, etc., can solve the problem of limited bonding amount of solid-phase microextraction head aptamer, restricting method application, and limiting service life and other problems to achieve the effect of maintaining activity and stability, not easy to enzymatic hydrolysis, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of amino-modified magnetic microspheres

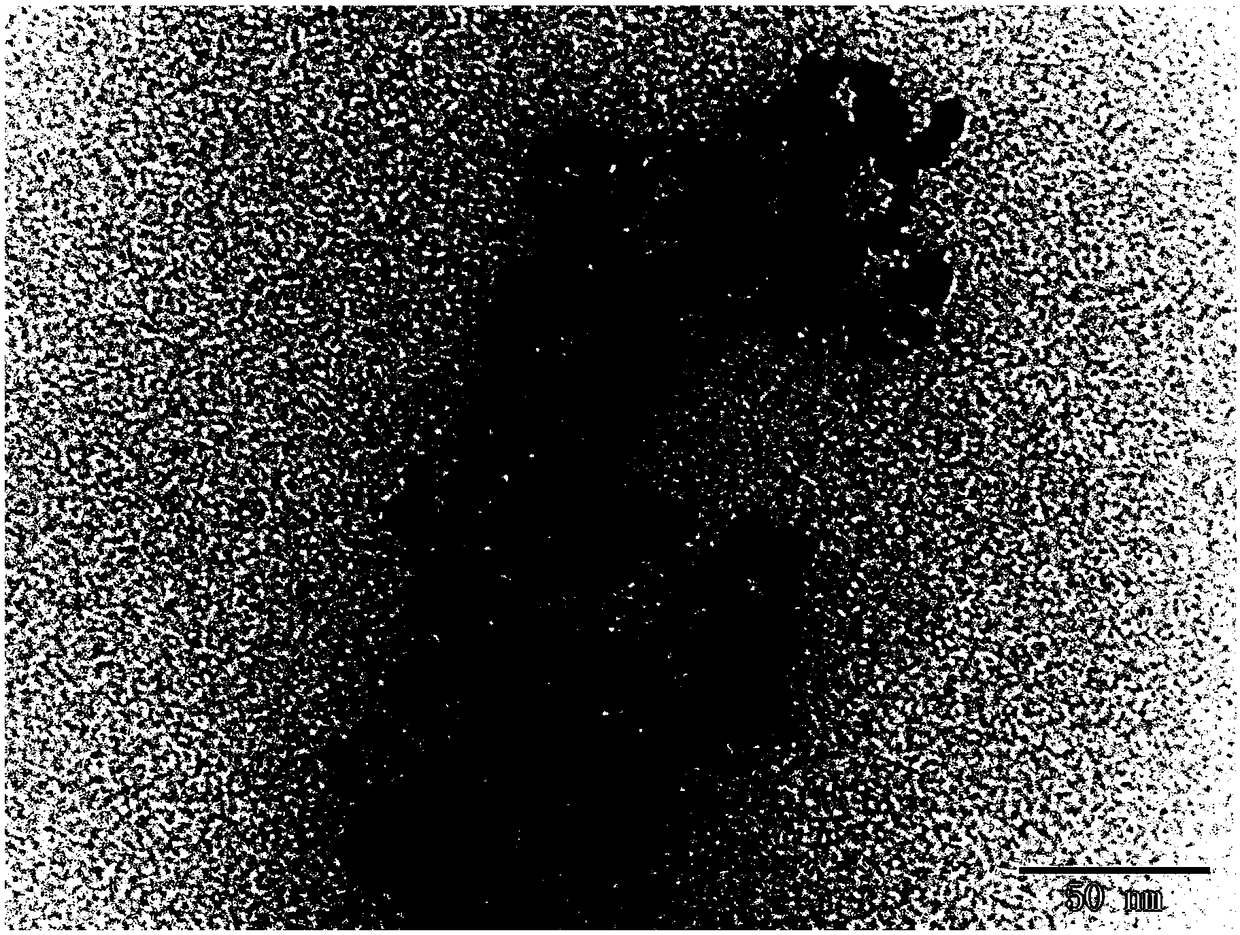

[0035] Weigh 2.00g PEG-6000, 2.40g NaOH in a 100mL beaker, add 50mL boiled and cooled deionized water to dissolve, transfer to a 500mL two-neck flask. Weigh 2.70g FeCl again 3 ·6H 2 O and 1.96 g FeCl 2 4H 2 O was dissolved in a 250mL beaker by adding 100mL of boiled and cooled deionized water and added dropwise to the mixture of PEG-6000 and NaOH. Keep the temperature of the water bath at 40°C, stir and react for 1 hour to get Fe 3 o 4 magnetic microspheres.

[0036] Fe 3 o 4 The magnetic microspheres were placed in a flask containing 50mL of n-propanol, 5mL of ammonia water was added after ultrasonication for 15min, 1ml of TEOS was added after an interval of 10min, and the reaction was stirred for 12h, then 10mL of 10% HCl was added for ultrasonic pickling, and finally 10mL of no Alcohol wash with water and ethanol to get SiO 2 / Fe 3 o 4 magnetic microspheres.

[0037] SiO obtained above 2 / ...

Embodiment 2

[0041] Example 2: Preparation of OTA nucleic acid aptamer-modified magnetic microspheres

[0042] Weigh 5 mg of amino-modified SiO obtained in Example 1 2 / Fe 3 o 4 Magnetic microspheres, add 800 μL Tris-HCl buffer solution (pH is 7.5, containing 0.1mol / L NaCl, 50mmol / L Tris, 1mmol / L MgCl 2 ), ultrasonic for 10min. Then add 1.2mL of LEDC / NHS mixture (molar ratio EDC:NHS=1:4), let it stand for 10min to activate, add 40μL of OTA aptamer solution (6.5μg / mL), shake and react at 25℃ for 16h to obtain OTA nucleic acid Aptamer-modified magnetic microspheres, labeled Apt-SF.

Embodiment 3

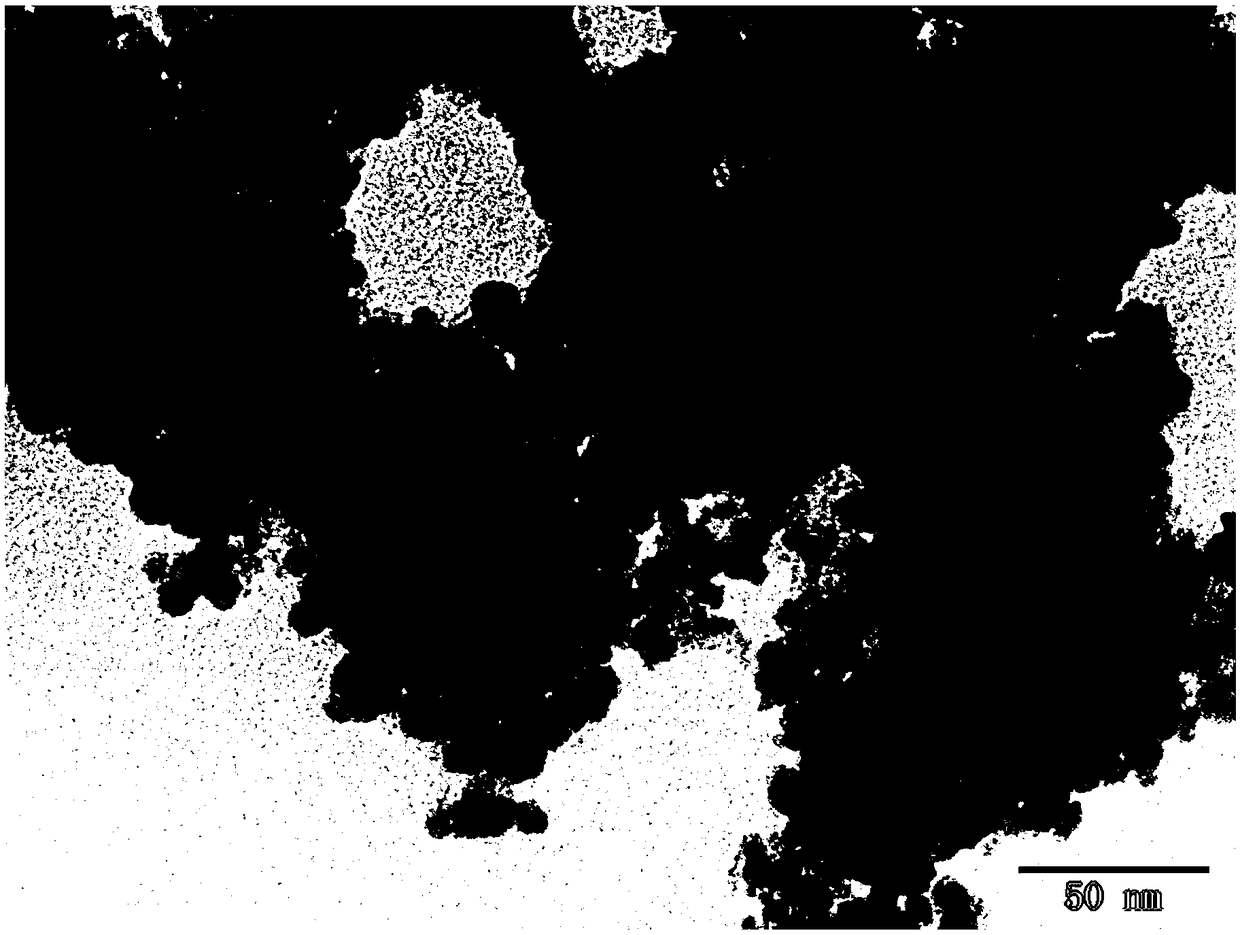

[0043] Example 3: Preparation of OTA nucleic acid aptamer-molecularly imprinted coated magnetic microspheres

[0044] Disperse the OTA nucleic acid aptamer-modified magnetic microspheres obtained in Example 2 in 5mL Tris-HCl buffer solution (pH is 7.5, containing 0.1mol / L NaCl, 50mmol / L Tris, 1mmol / L MgCl 2 ), add 0.205 μmol / L template molecule OTA, shake and incubate for 90 min, then perform magnetic separation, and then wash repeatedly with buffer solution to remove unbound template molecules. Then, 145 μmol functional monomer MAA (methacrylic acid) was added, and the reaction was shaken at room temperature for 30 minutes.

[0045] Next, 11.1 mg of N,N-methylenebisacrylamide, 33.3 μL of 0.0438 mol / L ammonium persulfate and 1 μL of tetramethylethylenediamine were added to the reaction mixture, and the reaction was shaken at 25°C for 4 hours under anaerobic conditions. Obtain OTA nucleic acid aptamer-molecularly imprinted coated magnetic microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com