Electrically-driven solid phase micro-extraction method and device thereof

A solid-phase microextraction column and electric-driven technology, which is applied in the field of electric-driven solid-phase microextraction and its devices, can solve the problems of adsorption and extraction of various target analytes, damage of solid-phase microextraction fiber head, unfavorable double Electric layer generation and other issues, to achieve the effect of improving analysis and detection sensitivity, easy assembly and adjustment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0036] 1) Pretreatment of metal wire 2: Take a section of stainless steel wire (30mm×1.2mm i.d.), clean it, and apply a thin layer of commercially available epoxy resin adhesive after drying, and wait until it is completely cured for later use.

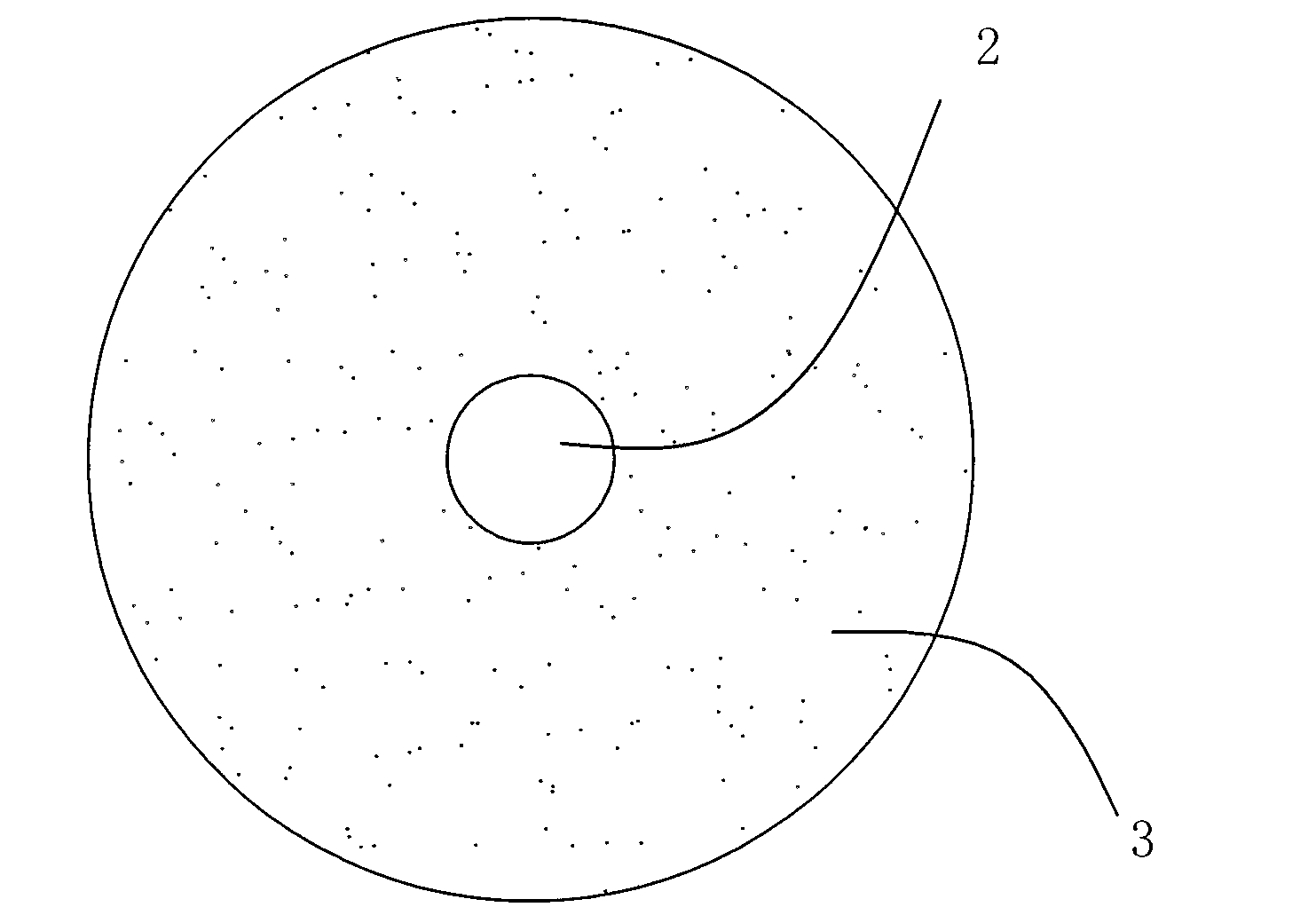

[0037] 2) Preparation of solid-phase microextraction column 3: take 4.0g PEG-1540 and heat it to melt, add 2.0g epoxy resin and mix for 2 minutes, cool to room temperature, then add 0.5g diethylenetriamine, and mix thoroughly for 2 minutes Obtain a uniform, transparent viscous liquid, pour it into a 1mL disposable syringe (made of polypropylene, the inner diameter of the tube is about 5mm), inject the liquid with a length of about 10-15mm, and immerse the aforementioned treated stainless steel wire 2 vertically in the reaction In the liquid, leave a section out of the reaction liquid, seal it and place it in an oven at 60°C for 24 hours of reaction, and take the prepared solid-phase microextraction column 3 out of the container.

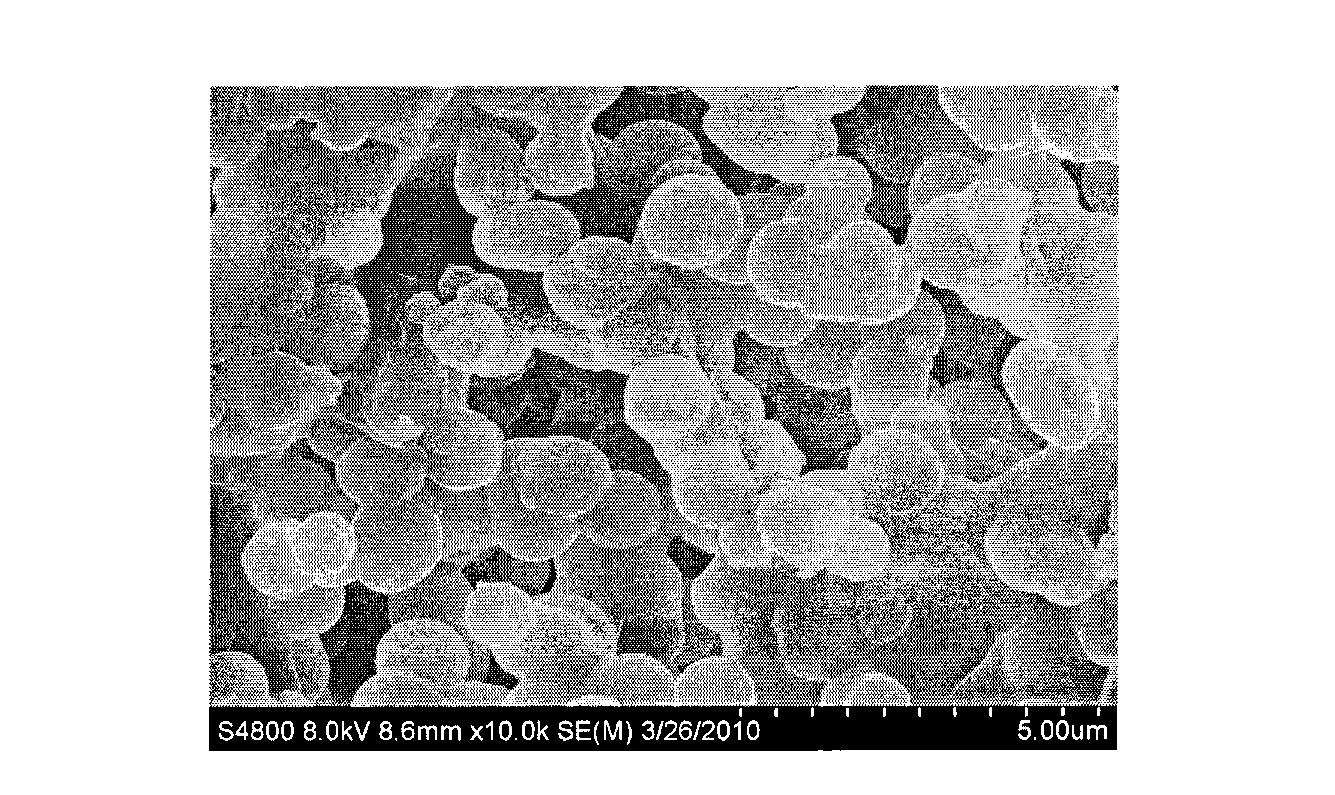

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com