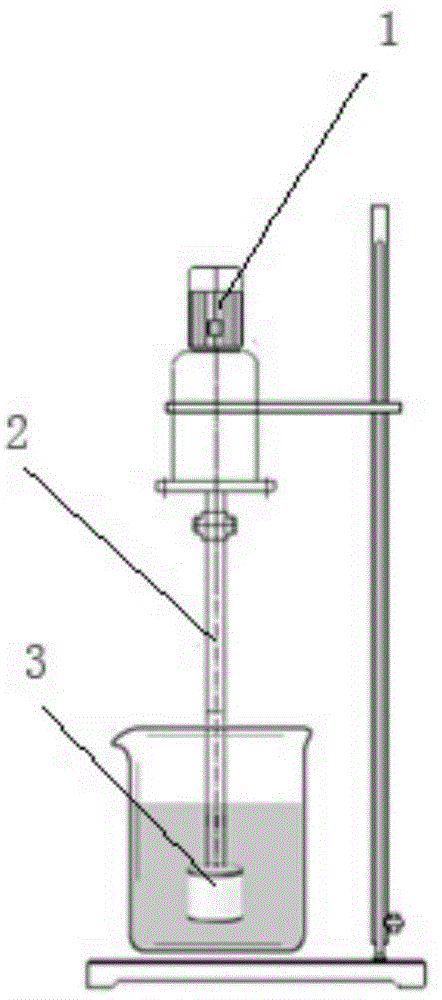

Rotational detachable film solid phase micro extraction device

An extraction device and a rotary technology, which is applied in the field of rotary detachable thin-film solid-phase microextraction devices, can solve the problems that the solid-phase microextraction stirring rod is easy to wear and it is difficult to use magnetic stirring, so as to improve the extraction volume and detection sensitivity, The effect of easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add the carbon molecular sieve particles into the polydimethylsiloxane prepolymer and stir evenly, then add the curing agent according to the ratio of 10:1, stir again for 10 minutes, mix well, put the mixture on the spin coater to make a mold, and then put it on the 80 Curing is carried out at a temperature of ℃ for 1 hour. After curing, the polydimethylsiloxane composite film embedded with carbon molecular sieves is heated to 120 ℃ and kept for 2 hours.

Embodiment 2

[0020] Add the carbon molecular sieve particles into the polydimethylsiloxane prepolymer and stir evenly, then add the curing agent according to the ratio of 10.5:1, stir again for 15 minutes, mix well, put the mixture on the spin coater to make a mold, and then put it on the 90 Cure at a temperature of 1.5 h. After curing, heat the polydimethylsiloxane composite film embedded with carbon molecular sieves to 130° C. and keep for 3 h.

Embodiment 3

[0022] Add the carbon molecular sieve particles into the polydimethylsiloxane prepolymer and stir evenly, then add the curing agent according to the ratio of 10:1~10.5:1, stir again for 10~15min, mix evenly and put the mixture on the spin coater Make molds, and then cure at 80-90°C for 1-1.5 hours. After curing, heat the polydimethylsiloxane composite film embedded with carbon molecular sieves to 120-130°C and keep it for 2-3 hours. Can.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com