Integrated porous polymer adsorption extraction stirring bar and its manufacturing method

A technology of porous polymers and stirring rods, applied in the direction of selective adsorption, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of limiting the sensitivity of sample analysis and the inability to use the depletion principle, etc., to achieve good mechanical properties and prolong service life , the effect of large extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

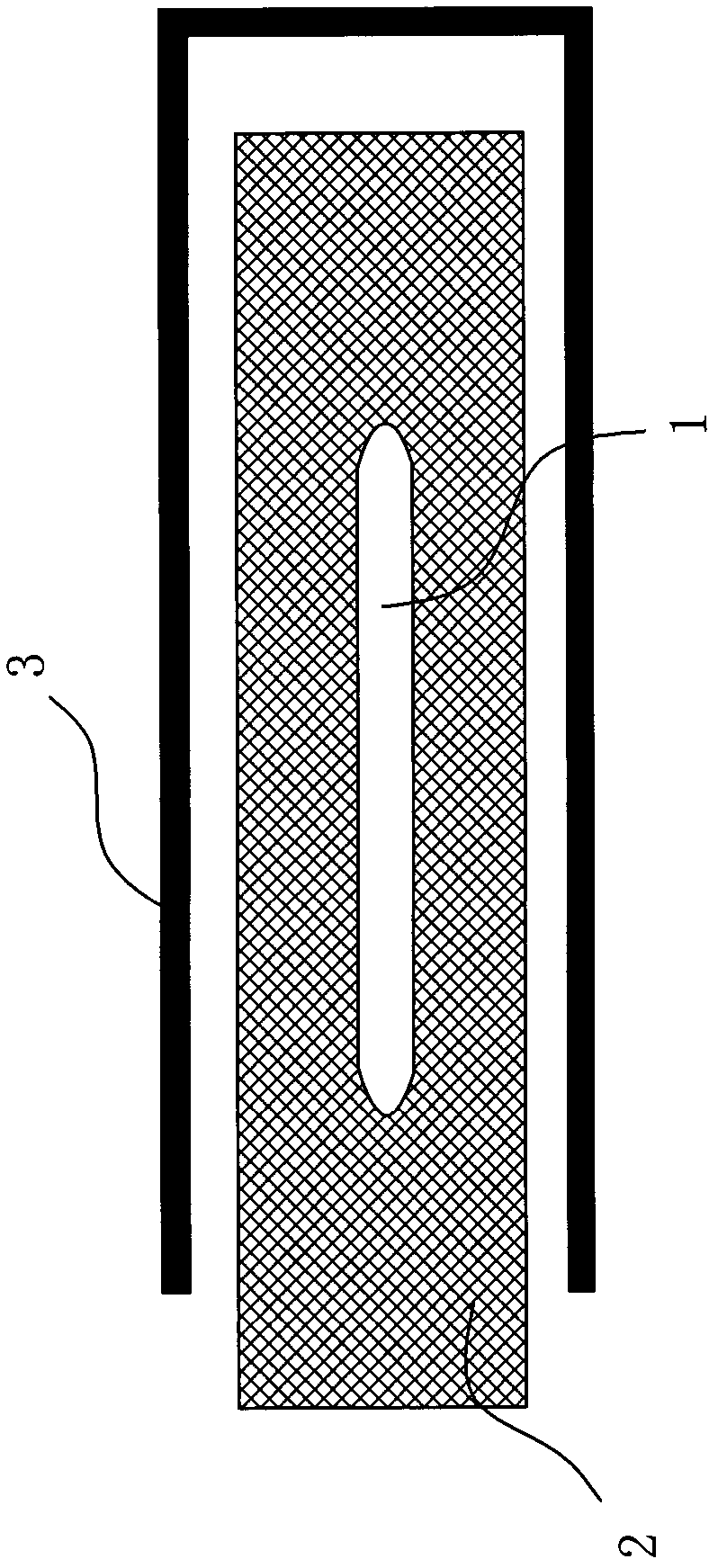

[0023] 1) Preparation of the stirring magnet: cut a section of 0.5mm stainless steel wire with a diameter of 10mm, clean it and dry it, then coat it with a commercially available acrylic modified epoxy or epoxy resin system glue, and wait until it is completely cured for later use.

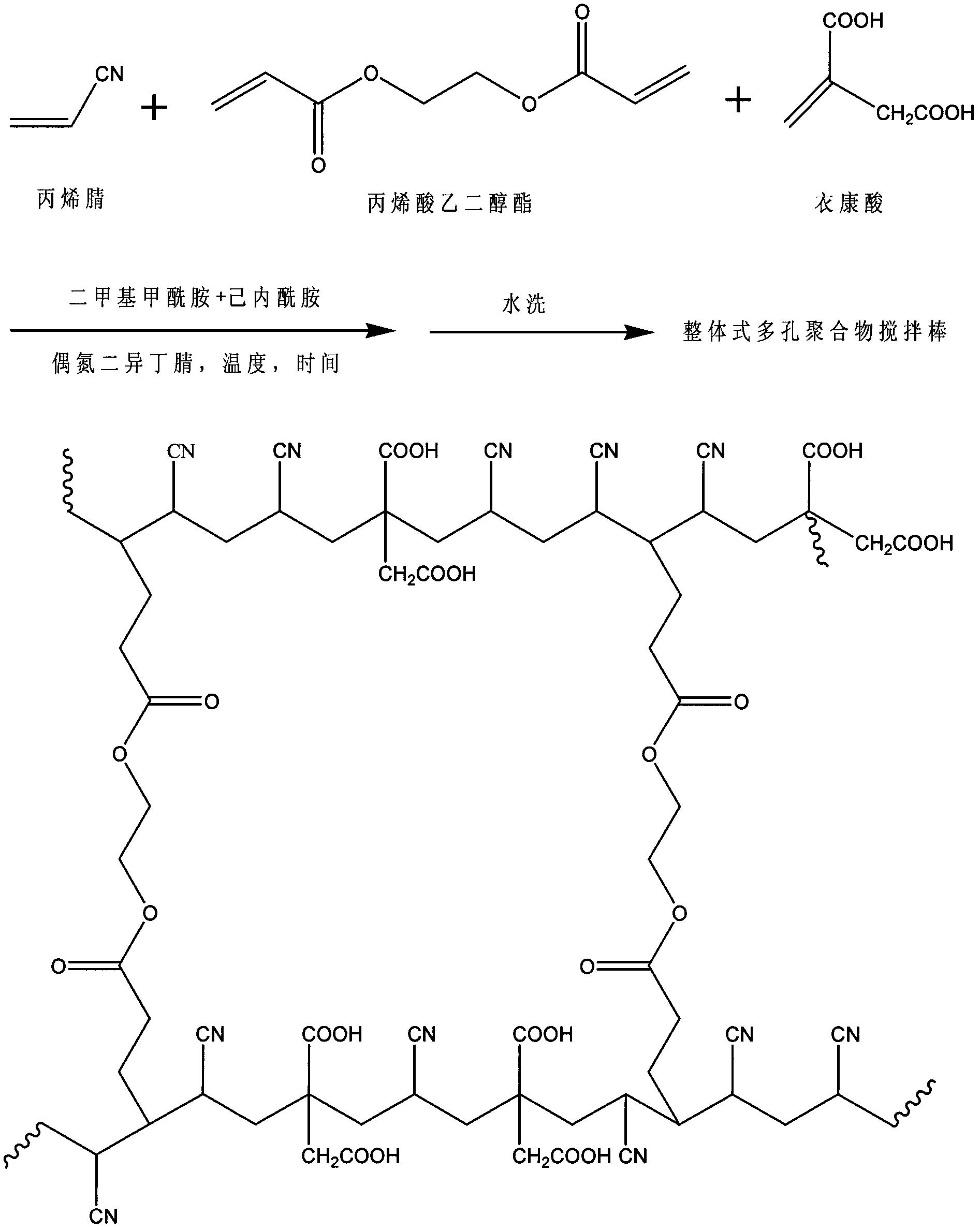

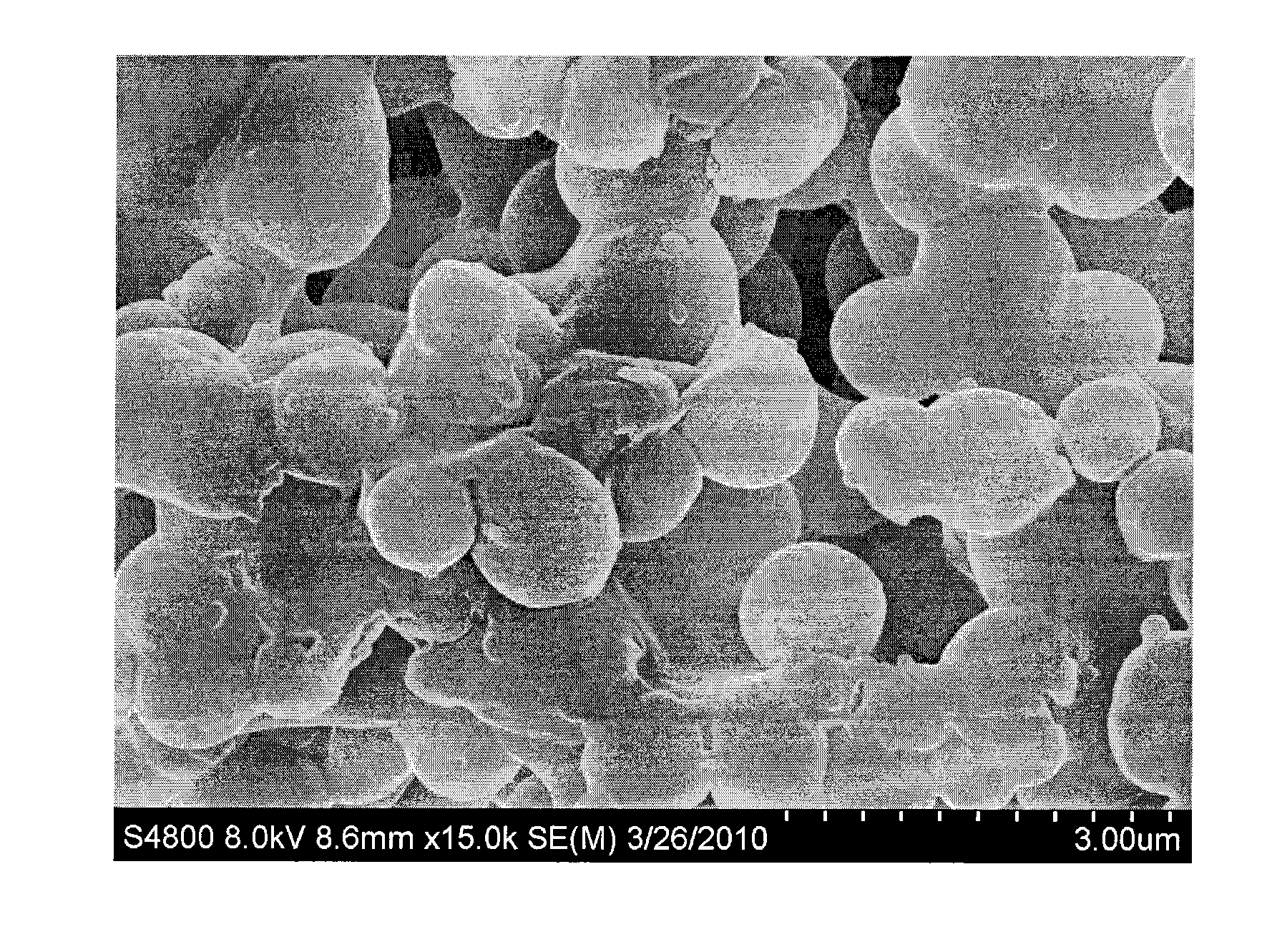

[0024] 2) Preparation of stirring bar for adsorption extraction: Take 8.0g acrylonitrile, 0.6g ethylene glycol acrylate, 0.2g itaconic acid, 6.0g dimethylformamide, 10.0g caprolactam, 20mg azobisisobutyronitrile, mix uniform. Pour it into a 0.5mL stainless steel tube (the inner diameter of the tube is about 2.5mm), inject the liquid with a length of about 12mm, seal it and place it in a 60°C oven for 1 hour to react, dip the aforementioned stainless steel wire vertically into the center of the reaction system, seal it and put it in the React in an oven at 65°C for 12 hours, and take out the prepared stirring rod. The schematic diagram of the polymerization process and the molecular structure of t...

Embodiment 2

[0027] The preparation of the stirring magnet is the same as in Example 1.

[0028]Take 8.0g of acrylonitrile, 1.2g of ethylene glycol acrylate, 0.8g of itaconic acid, 4.0g of dimethylformamide, 12.0g of caprolactam, and 30mg of azobisisobutyronitrile, and mix them evenly. Pour it into a 1mL stainless steel tube (the inner diameter of the tube is about 5mm), inject the liquid with a length of about 16mm, seal it and place it in a 70°C oven for 0.5h, dip the aforementioned stainless steel wire vertically into the center of the reaction system, seal it and place it in the After reacting in an oven at 70°C for 6 hours, the prepared stirring rod was taken out, washed repeatedly with deionized water until the porogen was completely removed, and placed in deionized water for later use.

Embodiment 3

[0030] Prepare the copper ion standard solution, adjust the pH=5 and place it in a small beaker, put the stirring rod prepared according to Example 1, at room temperature at a speed of 200r min -1 Under adsorption extraction for 20min, take out the stirring rod. with 2 mL of 5% HNO 3 Analyze at a certain stirring speed, and measure the ion concentration in the eluent by atomic emission spectrometry, and select 324.754nm as the measuring wavelength. The recovery rate of the standard addition reached over 98%, the relative standard deviation was 4.1%, and the detection limit was 3.2ng mL -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com