Method for extracting and separating light rare earth elements by using dual-functional ionic liquid

A technology of light rare earth elements and ionic liquids, which is applied in the field of extraction and separation of light rare earth elements using dual-functional ionic liquids, can solve the problems of stripping difficulties, secondary pollution, etc., and achieve broad application prospects, short equilibration time, and good separation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the method for extracting and separating light rare earth elements using a bifunctional ionic liquid is carried out according to the following steps:

[0035] (1) The rare earth chloride solution containing lanthanum is used as the raw material solution, the concentration of lanthanum in the raw material solution is 0.04mol / L, and the pH is 5.5.

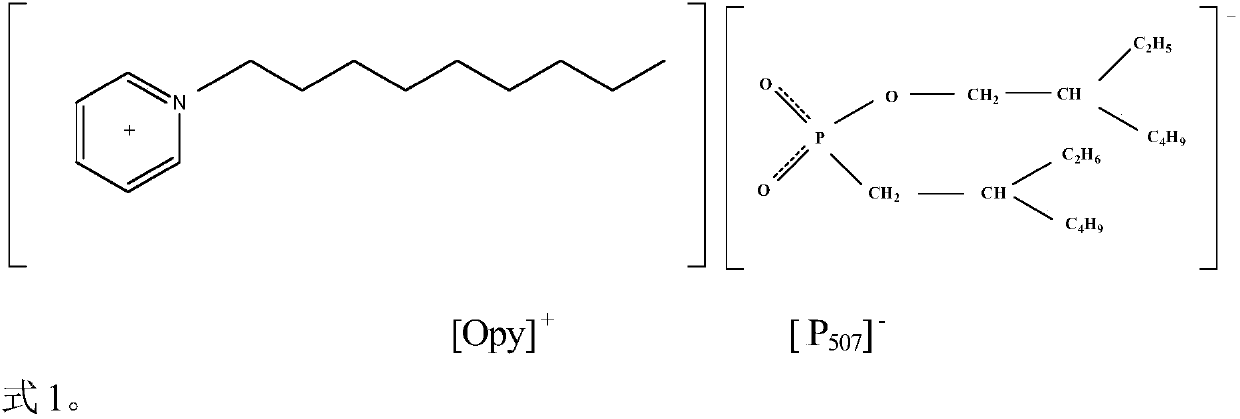

[0036] (2) Configure bifunctional ionic liquid as extractant, select n-amyl alcohol as diluent, N-octylpyridinium chloride salt and P 507 The molar ratio is 1:1, P 507 The concentration of 0.1mol / L, the concentration of N-octylpyridinium chloride salt is 0.1mol / L, P 507 The saponification rate is 100%.

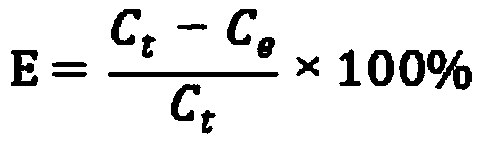

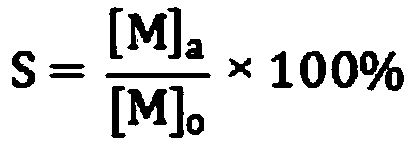

[0037] (3) Mix and extract the raw material liquid and the bifunctional ionic liquid in an oscillator, the mixing ratio is O / A=1:1, the rotation speed during the extraction process is 50r / min, the extraction time is 30min, the extraction temperature is 25°C, and the extraction After completion, the mixed...

Embodiment 2

[0040] In this embodiment, the method for extracting and separating light rare earth elements using a bifunctional ionic liquid is carried out according to the following steps:

[0041] (1) A rare earth chloride solution containing cerium is used as a raw material solution, the concentration of cerium in the raw material solution is 0.02mol / L, and the pH is 1.

[0042] (2) Configure bifunctional ionic liquid as extractant, select n-amyl alcohol as diluent, N-octylpyridinium chloride salt and P 507 The molar ratio is 1:3, P 507 The concentration of 0.08mol / L, the concentration of N-octylpyridinium chloride salt is 0.08mol / L, P 507 The saponification rate is 100%.

[0043] (3) Mix and extract the raw material liquid and the bifunctional ionic liquid in an oscillator, the mixing ratio is O / A=1:1, the rotation speed during the extraction process is 75r / min, the extraction time is 25min, the extraction temperature is 35°C, and the extraction After completion, the mixed solution wa...

Embodiment 3

[0046] In this embodiment, the method for extracting and separating light rare earth elements using a bifunctional ionic liquid is carried out according to the following steps:

[0047] (1) The rare earth chloride solution containing praseodymium is used as the raw material solution, the concentration of praseodymium in the raw material solution is 0.01mol / L, and the pH is 2.5.

[0048] (2) Configure bifunctional ionic liquid as extractant, select n-amyl alcohol as diluent, N-octylpyridinium chloride salt and P 507 The molar ratio is 1:1, P 507 The concentration of 0.05mol / L, the concentration of N-octylpyridinium chloride salt is 0.05mol / L, P 507 The saponification rate is 100%.

[0049] (3) Mix and extract the raw material liquid and the bifunctional ionic liquid in an oscillator, the mixing ratio is O / A=1:1, the rotation speed during the extraction process is 100r / min, the extraction time is 20min, the extraction temperature is 15°C, and the extraction After completion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com